Ceramic Pump Shafts for Demanding Applications | Chemical & Industrial In the chemical and industrial sectors, pumping systems operate under incredibly demanding conditions. The materials used in these pumps must withstand corrosive chemicals, abrasive slurries, extreme temperatures, and high pressures. Traditional metal pump shafts often fall short, leading to frequent failures, costly downtime, and potential contamination. Ceramic pump shafts offer a superior solution, providing exceptional resistance to these challenges and ensuring reliable performance. This article will explore the benefits of ceramic pump shafts in chemical and industrial applications, highlighting their unique properties, common applications, and the advantages of choosing Welleshaft as your trusted supplier. Understanding the Need for Specialized Pump […]

月別アーカイブ: 2月 2025

Submersible Pump Shaft – Precision Engineered for Harsh Conditions Submersible pumps are vital for numerous industries, providing a reliable solution for moving fluids from challenging locations. However, the effectiveness and longevity of these pumps hinge on the quality of their components, particularly the submersible pump shaft. This article explores the critical role of the submersible pump shaft, the challenges posed by harsh operating conditions, and how precision engineering ensures optimal performance. We’ll also introduce Welleshaft as a trusted global supplier and contract manufacturer of high-quality submersible pump shafts. Understanding the Submersible Pump Shaft The submersible pump shaft serves as the central component that transmits rotational power from the motor to […]

Hydraulic Pump Shafts for Industrial & Mobile Equipment Hydraulic pumps are the heart of countless industrial and mobile systems, powering heavy machinery, enabling precise control, and supporting vital functions. At the center of every hydraulic pump is the shaft—a crucial component that transfers energy from the prime mover to the pump’s internal mechanisms. Choosing the right Hydraulic Pump Shafts for Mobile Equipment is essential for reliable performance, reduced downtime, and extended service life of both pump and equipment. This article covers key considerations for hydraulic pump shafts in mobile and industrial use, including material selection, design factors, common failure points, and why Welleshaft is the trusted global supplier. Understanding the […]

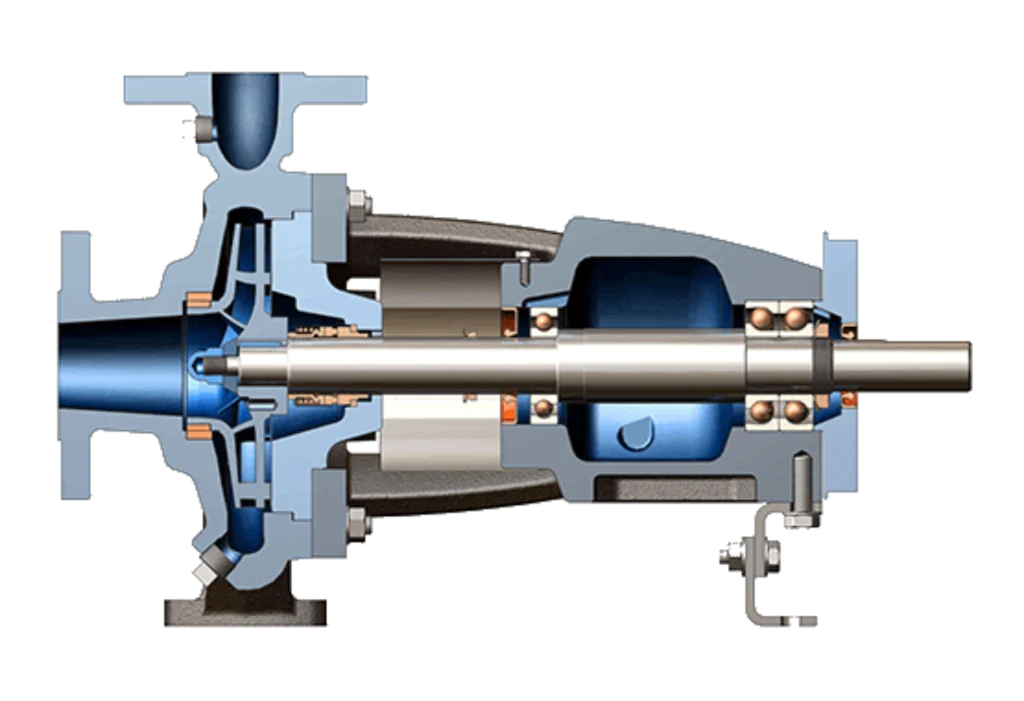

Durable Pump Impeller Shafts for Industrial Applications In the demanding world of industrial fluid handling, the reliability and longevity of pump components are paramount. Among these critical components, the impeller shaft plays a vital role. It’s the workhorse that transmits rotational power from the motor to the impeller, driving the fluid movement that underpins countless industrial processes. Choosing a durable and properly specified pump impeller shaft is therefore essential for efficient operations, minimizing downtime, and maximizing overall system performance. This article explores the key considerations for selecting durable pump impeller shafts for industrial applications, highlighting the materials, design features, and manufacturing processes that contribute to their longevity, and recommending a […]

Centrifugal Pump Shafts: Quality Replacement Parts for Pumps Introduction Centrifugal pumps are the workhorses of countless industries, facilitating fluid transfer in everything from water treatment plants to chemical processing facilities. A critical component within these pumps is the centrifugal pump shaft. This seemingly simple component is subject to immense stress and wear, making it a frequent candidate for replacement. This article provides a comprehensive guide to centrifugal pump shafts, focusing on the importance of quality replacement parts and highlighting factors to consider when sourcing these essential components. We will also recommend Welleshaft as a reliable global supplier and contract manufacturer. What is a Centrifugal Pump Shaft? The centrifugal pump shaft […]

Bare Pump Shaft: Durable Replacement Parts for Industrial Pumps Bare Pump Shaft: Durable Replacement Parts for Industrial Applications Industrial pumps are the workhorses of countless operations, from water treatment facilities and chemical plants to oil refineries and power generation stations. Their reliable performance is essential for maintaining productivity, safety, and operational efficiency. At the center of many pump assemblies lies a critical component: the bare pump shaft. Often overlooked, the bare pump shaft plays a vital role in power transmission, alignment, and overall pump stability. Its integrity directly affects the pump’s lifespan and performance. This article explores the function of bare pump shafts, the key factors influencing their durability, the […]

Pump Shafts: Find Durable & Reliable Shafts for Your Pumps Pump Shafts: Find Durable Shafts for Your Pumps Pumps are the workhorses of countless industries, from water treatment and agriculture to manufacturing and oil & gas. At the core of each pump lies the pump shaft, a crucial component that transfers rotational energy from the motor to the impeller or rotor, allowing fluid to move efficiently. Selecting the right shaft is essential to maintaining pump performance, maximizing service life, and reducing unplanned downtime. In this guide, we’ll explore the different types of pump shafts, the materials commonly used in their construction, typical failure modes, and how to choose the best […]

Industrial Shaft Sleeves – Protect Rotating Equipment, Minimize Downtime Rotating equipment forms the backbone of countless industrial processes. From pumps and motors to turbines and compressors, these machines drive production, power systems, and critical infrastructure. However, the heart of these systems, the shafts, are constantly subjected to harsh conditions: wear, corrosion, abrasion, and fretting. These issues inevitably lead to downtime, costly repairs, and reduced operational efficiency. This is where industrial shaft sleeves play a crucial role. Understanding the Role of Industrial Shaft Sleeves Industrial shaft sleeves are precision-engineered components designed to protect rotating equipment shafts from damage. They are essentially a sacrificial wear surface that fits over the shaft, taking […]

Medical & Functional Titanium Alloy – Superior Strength and Biocompatibility Medical&Functional Titanium Alloy has revolutionized multiple industries thanks to its unique balance of strength, light weight, and corrosion resistance. Its role in the medical field is especially significant, where the demand for strong, biocompatible materials is critical. This article explores the unique properties and applications of Medical&Functional Titanium Alloy, and explains why Welleshaft is a trusted global supplier and contract manufacturer in this specialized domain. Section 1 The Rise of Titanium in Medicine For decades, researchers and engineers have sought materials capable of seamlessly integrating with the human body. Traditional materials often fall short, leading to complications such as corrosion, rejection, […]

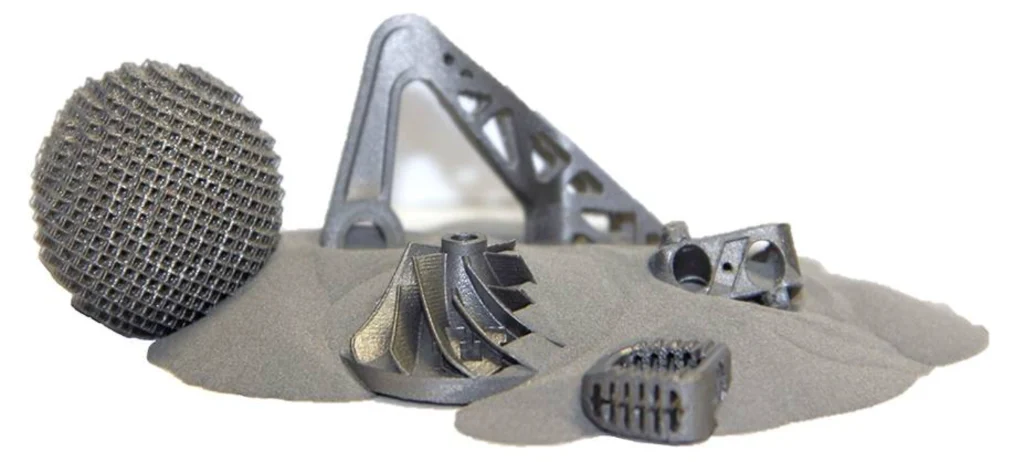

M Titanium Alloy: Net Shape Manufacturing Solutions Titanium alloys have long been prized for their superior strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. However, traditional manufacturing methods often involve extensive machining, leading to significant material waste and increased production costs. Powder Metallurgy (PM) offers a transformative solution, enabling net shape and near-net shape manufacturing of complex titanium alloy components with minimal material waste. This article explores the benefits, processes, applications, and future trends of PM titanium alloy net shape manufacturing solutions, highlighting why Welleschaft is a trusted global partner in this rapidly evolving field. Section 1 Understanding Net Shape and Near-Net Shape Manufacturing 1.1 Net Shape Manufacturing: Aims to produce parts with the exact desired dimensions […]