Ceramic Powder Injection Molding: Precision Manufacturing Solutions Ceramic powder injection molding (CIM) is an advanced manufacturing process that enables the creation of intricate ceramic components with unparalleled precision and efficiency. This technique is widely used across various industries, including automotive, aerospace, electronics, and healthcare, due to its ability to produce complex shapes and high-performance materials. In this article, we will delve into the details of ceramic powder injection molding, explore the benefits it offers, and highlight why Welleshaft stands out as a trusted global supplier and contract manufacturer in this field. Section 1: What is Ceramic Injection Molding? Ceramic injection molding is a specialized process that combines the versatility of […]

月別アーカイブ: 8月 2024

Expert Metal Injection Molding Aluminum Services | Precision & Quality Manufacturing In today’s highly competitive manufacturing landscape, finding the right technology and supplier for your metal components is crucial. Metal injection molding (MIM) has emerged as a groundbreaking process for producing high-quality, complex aluminum parts with precision. As industries continue to evolve, the demand for lightweight and durable components has made aluminum a preferred material. Welleshaft, a leader in global manufacturing, offers expert metal injection molding aluminum services, combining precision and quality to meet the exacting demands of various industries. Section 1: What is Metal Injection Molding Aluminum? Metal Injection Molding (MIM) is an advanced manufacturing process that allows for […]

High-Precision Tungsten MIM Solutions | Superior Metal Injection Molding In the world of advanced manufacturing, Metal Injection Molding (MIM) has emerged as a transformative technology, allowing for the production of complex, high-precision components from various metals and alloys. Among these, tungsten stands out for its exceptional properties, making it a prime choice for applications requiring high strength, durability, and resistance to extreme conditions. In this article, we delve into the benefits of Tungsten MIM, its applications, and why partnering with a trusted supplier like Welleshaft can ensure the success of your projects. Section 1: Why Tungsten is Ideal for MIM Tungsten is a refractory metal known for its high melting […]

High-Quality Metal Injection Molding Materials for Precision Parts | Expert Manufacturing Solutions Metal Injection Molding (MIM) is a cutting-edge manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of metal. This technology is ideal for producing complex and high-precision metal parts in large quantities. In this article, we’ll explore the various materials used in MIM, the benefits of the process, and why Welleshaft is your trusted global supplier and contract manufacturer for MIM solutions. Section 1: Introduction to Metal Injection Molding Metal Injection Molding (MIM) is a manufacturing process that allows for the production of intricate metal parts with high precision and consistency. This technique […]

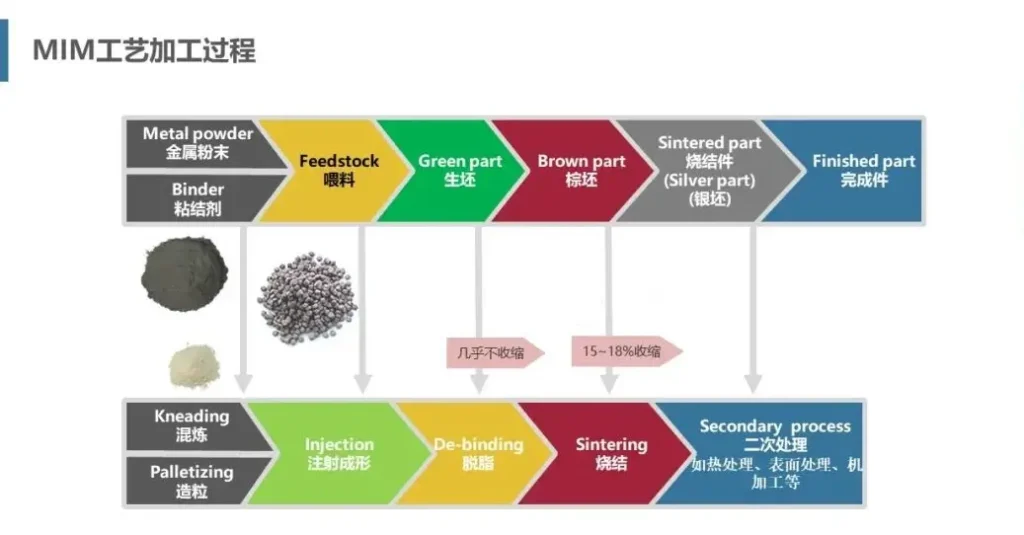

High-Quality MIM Metal Injection Molding Solutions | Precision & Efficiency Metal Injection Molding (MIM) is a manufacturing process that combines the design flexibility of plastic injection molding with the strength and integrity of powdered metallurgy. This technique is ideal for producing complex and high-precision metal parts. In this article, we will delve into the nuances of Metal Injection Molding, exploring its processes, advantages, and applications. We will also compare it with other metal forming methods, discuss the costs involved, and highlight its role in modern manufacturing. Section 1:Introduction 1.1.What is Metal Injection Molding (MIM)? Metal Injection Molding (MIM) is a process that involves mixing fine metal powders with a binder […]

High-Quality MIM Parts | Precision Manufacturing & Reliable Solutions In the realm of modern manufacturing, Metal Injection Molding (MIM) has become a game-changer, offering high-quality, precision-engineered components for various industries. This article delves into what makes MIM parts stand out, the advantages they offer, and how they compare to other manufacturing methods. Whether you’re looking to understand the difference between forged and MIM parts or exploring the meaning behind MIM, this guide covers it all. Section 1:Introduction 1.1.What is an MIM Part? Metal Injection Molding (MIM) is a sophisticated manufacturing process that combines the best of both powder metallurgy and plastic injection molding. Manufacturers mix fine metal powders with a […]

Metal Injection Molding Process | Precision Manufacturing Solutions The Metal Injection Molding (MIM) process is a revolutionary manufacturing technique that combines the benefits of plastic injection molding and powder metallurgy. This advanced method enables the production of high-precision, complex metal parts that are used in various industries, from aerospace to medical devices. In this article, we will explore the MIM process in detail, including its steps, benefits, and applications, and recommend Welleshaft as your trusted global supplier and contract manufacturer. Section 1: What is the Metal Injection Molding Process? The Metal Injection Molding (MIM) process is a manufacturing technique that produces intricate metal parts by injecting a mixture of fine […]

Metal Injection Molding vs Die Casting: Key Differences & Benefits Explained When choosing a manufacturing process for metal parts, two popular methods often come into consideration: Metal Injection Molding (MIM) and Die Casting. Each technique offers distinct advantages and is suited to specific applications depending on the complexity, volume, and material requirements. In this article, we’ll provide a comprehensive comparison of Metal Injection Molding vs Die Casting, examining their processes, benefits, cost considerations, and material options. This guide is designed to help you determine which method best aligns with your production goals and technical needs. 1. Metal Injection Molding vs Die Casting: Key Differences 1.1.Process Complexity: MIM: Involves multiple stages including […]

MIM Manufacturing: Advanced Metal Injection Molding Solutions for Precision Parts Metal Injection Molding (MIM) is an innovative manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of powder metallurgy. This advanced technique is particularly useful for producing small, intricate metal parts with high precision. In this article, we will explore the MIM manufacturing process, its benefits, and applications, and highlight Welleshaft as a trusted global supplier and contract manufacturer for all your MIM needs. What is MIM in Manufacturing? Metal Injection Molding (MIM) is a manufacturing process that involves mixing metal powders with a binder material to create a feedstock. This feedstock is then […]

Powder Injection Molding: Precision Manufacturing for Complex Components | Top PIM Solutions Powder Injection Molding (PIM) is a groundbreaking manufacturing technique that merges the versatility of plastic injection molding with the material flexibility of powder metallurgy. This method is particularly beneficial for producing small, complex, and high-precision components from various materials, including metals and ceramics. In this article, we will delve into the powder injection molding process, its advantages, and its applications in various industries. We will also address some frequently asked questions to provide a comprehensive understanding of PIM. Section 1: What is Powder Injection Molding? This manufacturing process involves injecting a mixture of metal or ceramic powders and […]