Understanding Roller Conveyors and Their Applications What Are Roller Conveyors? Roller conveyors are essential in material handling systems, consisting of rollers within a frame that move objects manually, by gravity, or power. Understanding roller conveyors is key to optimizing transport of boxes, crates, pallets, plastic totes, and trays in warehouses and manufacturing operations. Versatility of Roller Conveyors Roller conveyors can be adapted with ancillary equipment like bends, gates, and turntables, adding flexibility to transfers, diverters, and stops in conveyor or automation systems. Available in mild steel, galvanized steel, plastic, and stainless steel, understanding roller conveyors helps tailor solutions to specific operational and environmental needs. Historical Background of Roller Conveyors The […]

月別アーカイブ: 6月 2024

Conveyor Rollers and How They Work: A Comprehensive Guide As a leading conveyor roller manufacturer, we understand the critical role these components play in modern logistics and production. Conveyor rollers are essential elements that facilitate the smooth and efficient movement of goods within various facilities. In this guide, we delve into the intricacies of conveyor rollers, their applications, types, and the benefits they bring to your operations. What are Conveyor Rollers? Conveyor rollers are cylindrical components integrated into the upper part of a conveyor frame. They are designed to move goods swiftly and efficiently from one point to another within a warehouse or production center. These rollers are a vital […]

Conveyor Roller Manufacturers: The Key to Efficient Material Handling In material handling and transportation, conveyor rollers play a crucial role in ensuring smooth, efficient movement of goods. Whether in agriculture, food and beverage, or medicine industries, the demand for a reliable Conveyor Roller Manufacturer is universal. This article explores conveyor roller manufacturing, covering types, advantages, and key considerations for companies investing in this essential equipment. Understanding Conveyor Rollers What are Conveyor Rollers? Industrial conveyor rollers are cylindrical tubes that facilitate the movement of items along a conveyor belt. Designed to handle a wide range of materials—from bulk products to delicate components—they are commonly used in industries like metal and plastic […]

The lead screw, especially the ball screw, has a number of significant advantages, which make it widely used in a variety of mechanical and automation systems. The following is a detailed overview of the advantages of the lead screw: 1. High precision: Ball screw can provide extremely high positioning accuracy and repeated positioning accuracy. Its precise manufacturing process and design ensure a tight fit between the screw and nut, enabling subtle and accurate displacement control. This is essential for applications that require high precision positioning, such as CNC machine tools, measuring equipment, and precision machinery. 2.Ball screws improve transmission efficiency by replacing sliding friction with rolling friction, reducing input power, […]

The role of the lead screw, especially ball screws, is vital in mechanical systems. They convert rotary motion to linear motion with high efficiency, precision, and load capacity, making them essential in CNC machines, automation systems, and other industrial applications. Welleshaft specializes in manufacturing high-performance lead screws tailored to meet these demanding requirements. 1. Motion conversion: The main function of the lead screw is to achieve the conversion of the form of motion, which can convert the rotating motion into a linear motion, or vice versa. This property is very useful in mechanical design, especially where linear displacement is required. 2. High transmission efficiency: By introducing steel balls, the ball […]

What are Plastic Gears? Plastic gears have become increasingly popular in various industries due to their unique advantages over traditional metal gears. This comprehensive guide will explore the structure, design, manufacturing processes, materials, types, benefits, disadvantages, and applications of plastic gears. Design Considerations for Plastic Gears Designing plastic gears requires careful consideration of various factors to ensure optimal performance and longevity. Key design aspects include: Tooth Profile: Involute Teeth: The most common design, ensuring smooth meshing and minimal noise. Helical Teeth: Provide quieter operation and better load distribution but require more complex manufacturing processes. Gear Geometry: Pitch: The distance between corresponding points on adjacent teeth. Module: The ratio of the […]

What is 3D Sand Printing and How Does it Work? 3D Sand Printing is an advanced additive manufacturing technique used to create sand molds and cores for casting metal components. Unlike traditional sand casting, which involves manually creating molds, 3D sand printing automates this process, significantly enhancing precision and reducing production times. How Does 3D Sand Printing Work? Design: The process begins with a 3D CAD model of the part to be cast. This digital model is created using CAD software, which allows for precise control over the design. Preparation: The 3D model is then converted into a format compatible with the 3D printer, typically an STL file. The design […]

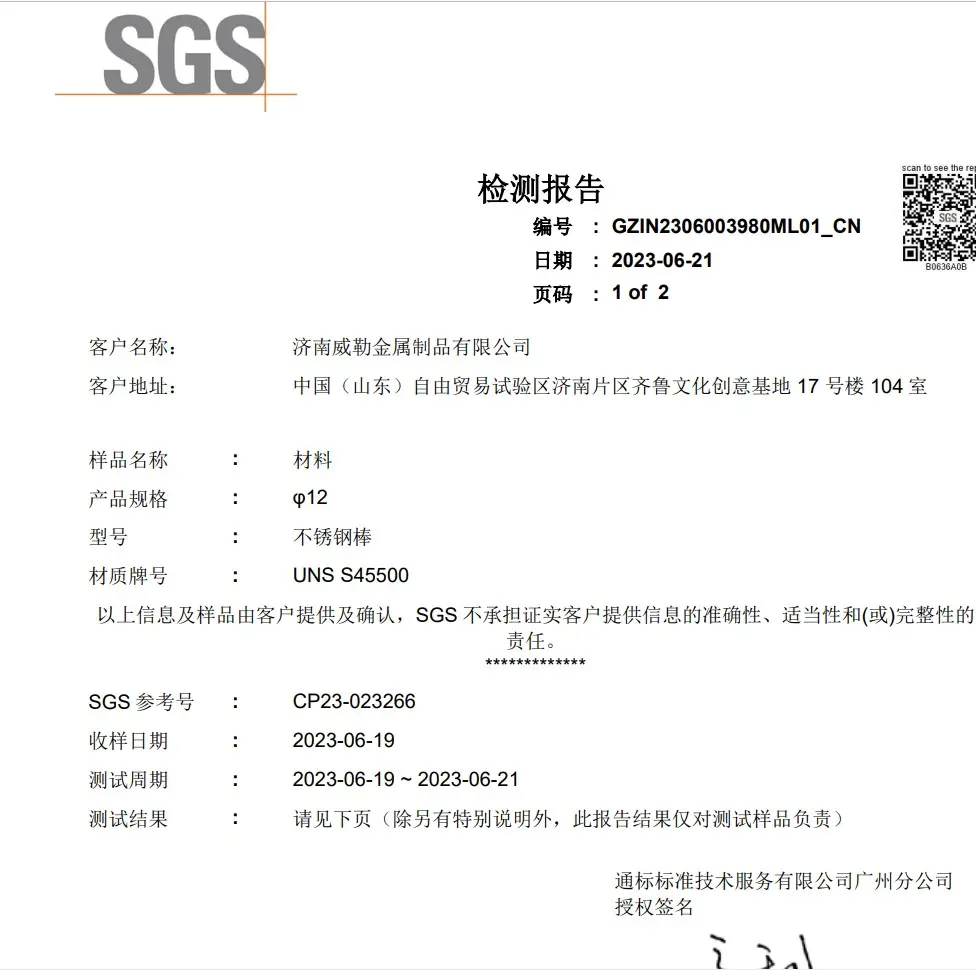

Everything You Need to Know About SS455 Stainless Steel: Properties, Machining, and Applications What is SS455 Stainless Steel? SS455 is a martensitic stainless steel that combines high strength, toughness, and corrosion resistance. Often chosen for its ease of fabrication and wear resistance, Stainless Steel Grade Custom 455 is ideal for applications requiring strong mechanical performance and durability in corrosive environments. Key Properties of SS455 Chemical Composition: SS455 contains high levels of chromium and nickel, with additional elements such as molybdenum and manganese to enhance its properties. Mechanical Properties: Tensile Strength: Approximately 850-1000 MPa Yield Strength: Around 500-600 MPa Hardness: Ranges from 25 to 35 HRC Elongation: About 15-20% Corrosion Resistance: […]

What is the Aluminium CNC Machining Processes? You can perform aluminum machining using various CNC machining processes available today. Some of these processes include: CNC Turning: In CNC turning operations, the workpiece rotates, while the single-point cutting tool stays stationary along its axis. Depending on the machine, either the workpiece or the cutting tool carries out feed motion against the other in order to achieve material removal. CNC Milling: CNC Milling operations are the most commonly used in machining aluminium parts. These operations involve the rotation of a multi-point cutting along its axis, while the workpiece stays stationary along its own axis. The cutting tool, the workpiece, or both move to […]

The production process of stainless steel fasteners mainly includes the following steps: 1. Material preparation: In the production process of stainless steel fasteners, choosing suitable materials such as 304, 316, and other high-strength stainless steels is fundamental to ensuring both product strength and corrosion resistance. 2. Material cutting: – Cutting stainless steel material to the appropriate size and shape, commonly used cutting processes include shearing, sawing, laser cutting, etc. 3. Molding processing: – Molding of stainless steel materials according to the shape and requirements of the product. Commonly used forming processes are stamping, drawing, cold heading and so on. In addition, the hot beating process is also an important molding […]