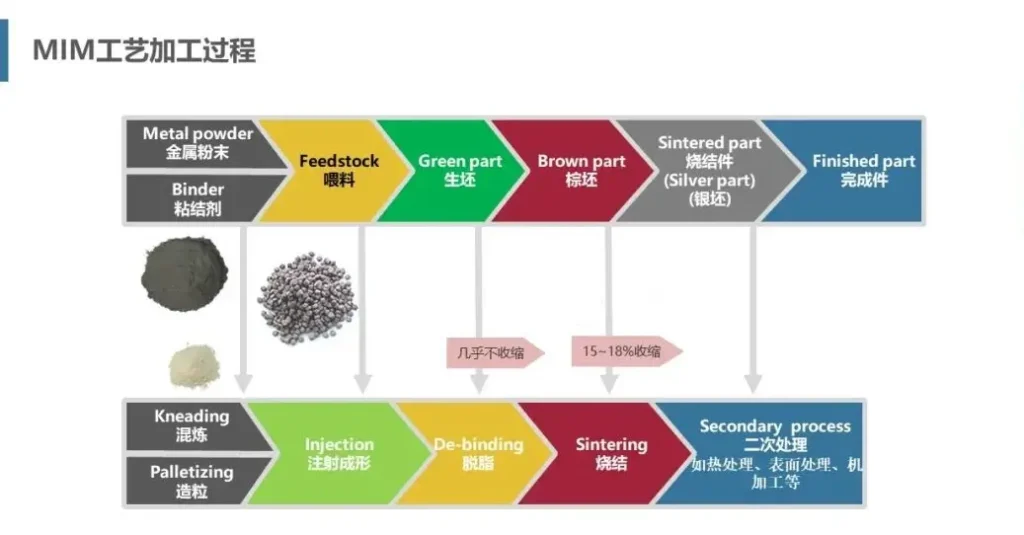

Metal Injection Molding Process | Precision Manufacturing Solutions The Metal Injection Molding (MIM) process is a revolutionary manufacturing technique that combines the benefits of plastic injection molding and powder metallurgy. This advanced method enables the production of high-precision, complex metal parts that are used in various industries, from aerospace to medical devices. In this article, we will explore the MIM process in detail, including its steps, benefits, and applications, and recommend Welleshaft as your trusted global supplier and contract manufacturer. Section 1: What is the Metal Injection Molding Process? The Metal Injection Molding (MIM) process is a manufacturing technique that produces intricate metal parts by injecting a mixture of fine […]

カテゴリーアーカイブ: Finishing

Explore essential knowledge on finishing processes, surface coating,plating,roughness levels, and inspection methods for non-ferrous and ferrous metals, stainless steel, plastics, and rubber. Learn how to choose the right surface solution for durability, aesthetics, or performance.

Top Metal Injection Molding Manufacturer | High-Precision Molding Solutions Metal Injection Molding (MIM) is revolutionizing how complex metal parts are manufactured, offering unparalleled precision, efficiency, and versatility. As industries continue to demand more sophisticated and reliable components, finding the right MIM manufacturer is crucial. This article will delve into why Welleshaft stands out as a top choice among metal injection molding companies, exploring our expertise, the industries we serve, and our global presence. Section 1: What is Metal Injection Molding? Metal Injection Molding (MIM) is a process that combines the versatility of plastic injection molding with the performance characteristics of metal. This technique involves mixing fine metal powders with a […]

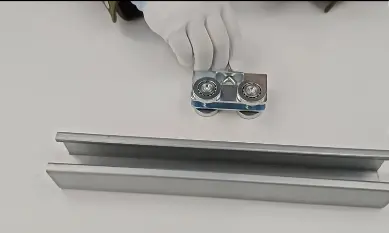

How Much Weight Can an Unistrut Trolley Hold? | Comprehensive Guide Unistrut trolleys are versatile and essential components in many industrial and construction applications. Knowing how much weight can an Unistrut trolley hold is crucial for maximizing their utility and ensuring safety. In this comprehensive guide, we will explore various aspects of Unistrut trolleys, including their weight capacity, types, applications, and more. What is a Unistrut Trolley? A Unistrut trolley is a movable assembly that runs along a Unistrut channel, providing support and mobility for various loads. If you’re wondering how much weight can an Unistrut trolley hold, it’s important to consider the specific model and application. These trolleys are […]

Premium Pump Wear Rings for Enhanced Performance & Durability Pump wear rings are essential components in ensuring the optimal performance and longevity of various pumping systems. These rings play a critical role in reducing friction, preventing wear, and maintaining the efficiency of pumps. In this article, we will explore the significance of premium pump wear rings,their types, materials, and how they contribute to enhanced performance and durability. We will also highlight why Welleshaft is the trusted global supplier and contract manufacturer for top-quality wear components. What Are Pump Wear Rings? Pump wear rings are critical components used in centrifugal pumps and other pumping systems. They are designed to reduce friction […]

High-Quality Pump Wear Rings for Enhanced Durability & Performance When it comes to ensuring the optimal performance and longevity of centrifugal pumps, wear rings play a crucial role. Understanding what wear rings are, their purpose, and how to maintain them effectively is essential for maximizing the efficiency of your pumping systems. This article delves into the key aspects of pump wear rings, including their types, materials, and maintenance practices, while recommending Welleshaft as a trusted global supplier and contract manufacturer for high-quality pump wear rings. What is a Wear Ring in a Centrifugal Pump? A wear ring is a critical component in centrifugal pumps designed to minimize leakage between the […]

High-Quality Casing Wear Rings – Durable and Reliable Solutions for Your Equipment Section 1: Introduction Wear rings are essential components in various mechanical systems, providing a protective layer between moving parts to minimize wear and tear. In industries such as hydraulics and pump manufacturing, wear rings play a crucial role in ensuring the efficiency and longevity of equipment. This article explores the importance of high-quality casing wear rings, their functions, materials, and the benefits of partnering with a trusted global supplier like Welleshaft. What Are Wear Rings? Engineers design wear rings, also known as guide rings or bearing rings, to guide and support moving parts within machinery. These components reduce […]

Boost Your Manufacturing Efficiency With Advanced Gear Milling Techniques Gear milling is one of those essentials, and it can significantly help determine the outcomes of your work. In this blog post, read why advanced gear milling methods are critical and how they may assist you in manufacturing. Understanding Gear Milling Gear milling involves cutting gear teeth using a milling cutter on the surface of a cylinder. Gears are vital parts of most mechanical systems, and this process produces the shape needed to work. The teeth of the gear need to be both precise and quality to fit into place and mesh perfectly. Forms of Gear Milling Manufacturers use various forms […]

The Critical Role of Engineering and Quality Control In the world of manufacturing, precision engineering and stringent quality control are paramount. Engineering excellence and quality inspection ensure automotive components and medical devices meet the highest durability and reliability standards. Engineering excellence and quality inspection are the twin pillars upon which the foundation of modern manufacturing stands.In today’s competitive global market, companies must maintain high product quality to meet soaring consumer expectations.At the heart of every successful manufacturing operation lies a robust engineering framework coupled with meticulous quality inspection protocols. This synergy ensures every component meets strict standards, delivering reliable, long-lasting functionality straight from production. Global Quality Certifications and Expertise At […]

- 1

- 2