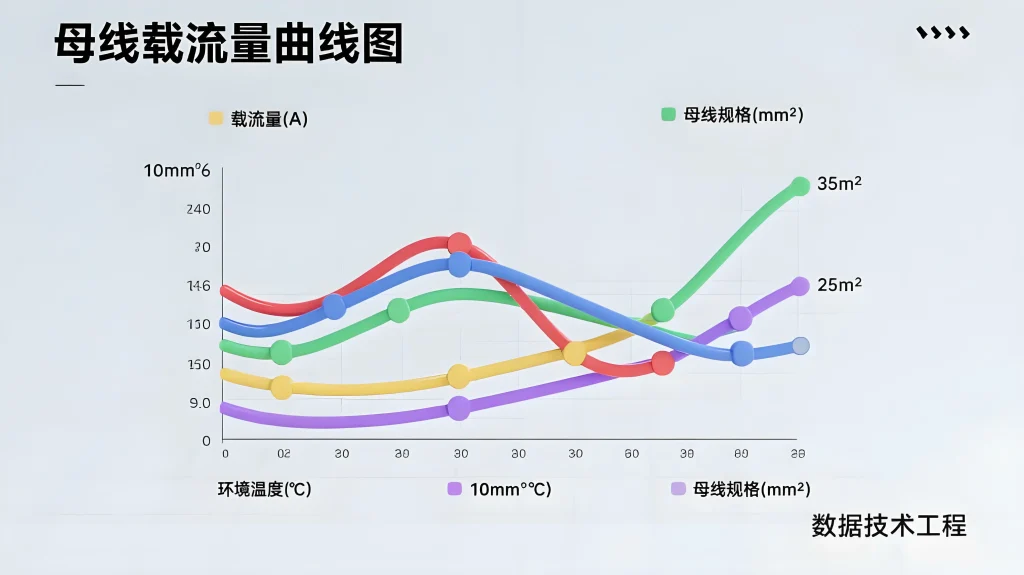

1.Busbar Ampacity Charts Explained | Copper & Aluminum Busbar Sizing Guide – Welleshaft Understanding Busbar Ampacity Charts is essential for engineers, electricians, and panel designers working with copper and aluminum busbars. These charts provide quick insights into how much current a busbar can safely carry, whether for AC or DC applications. However, interpreting an ampacity chart requires more than reading numbers—it involves assessing physical performance, heat dissipation, and application-specific variables. At Welleshaft, we help professionals navigate the complexities of busbar sizing by offering tools, testing, and expert guidance to ensure your system meets both electrical and thermal performance requirements 2.What Is an Ampacity Chart? The term ampacity combines “ampere” and “capacity,” referring […]

カテゴリーアーカイブ: products

Discover our wide range of high-quality industrial products including Gears, Seals, O-rings, Fasteners, Shafts, Flanges, Tubes, EV Housings, Heat Sinks, Welding Structures, and more. We specialize in customized sourcing solutions across diverse sectors—automotive, aerospace, heavy machinery, robotics, smart manufacturing, medical devices, and more. Our one-stop supply chain service streamlines procurement, matches specialized product requirements with trusted manufacturers, and solves the complexities of multi-category custom part sourcing. Partner with us to simplify your supply needs and ensure consistent quality, flexibility, and efficiency at every step.

1.Aluminum Bus Bars and Electrical Connectors: A Complete Guide by Welleshaft Aluminum bus bars, like the well-known 6101 aluminum bus bar and tinned bus bars, are key parts in electrical power systems. This guide by Welleshaft explains everything about aluminum busbar uses, compares aluminum bus bar vs copper, covers aluminum bar sizes for panel designs, and details electrical busbar connectors. Whether you’re curious about what is busbar used for or need info on busbar in electrical setups like EV batteries and solar inverters, this article covers it all. 2.What Is a Bus Bar in Electrical Systems? A bus bar in electrical work is a metal strip or bar—usually aluminum or copper—that moves electric current around inside equipment […]

1.Flexible Copper Connectors & Braided Wire Solutions | Welleshaft Ensure Stronger Electrical Connections Across Industries with Our Flexible Copper Braid Connectors. (1)What Are Flexible Copper Connectors and Why Are They Important? Flexible copper connectors—also called copper flexible connectors or braided wire connectors—are used to bridge electrical parts that move, vibrate, or expand. These connectors are vital in areas like electric vehicle battery systems, switchgear, BMS setups, solar panels, and power grid infrastructure. Welleshaft supplies reliable flexible copper busbars, braid connectors, and braided flexible fittings for use in high-current and precision-control setups. 2.Key Benefits of Braided and Flexible Copper Connections 1.Reliable Current Handling Copper braid attachments and braided copper conductors carry high currents […]

1.Custom Copper Bus Bar Fabrication | Welleshaft Welleshaft stands as a top copper busbar manufacturer and formed busbar fabricator, making high-grade custom bus bars and copper bus bars for industries like automotive, electronics, power distribution, and green energy. Here, we explain what is a electrical bus bar, share key uses of custom copper bus bars, and show our busbar fabrication skills. 2.What Is a Bus Bar? Getting to Know Electrical Copper Bus Bars A bus bar — also called busbard or buss bar — is a metal conductor that spreads electrical power smoothly. Copper and aluminum are the go-to metals. Using a tin plated copper bus bar adds corrosion resistance, common in electrical grids and commercial setups. What […]

1.What Is a Busbar? | Electrical Bus Bar Guide by Welleshaft Electrical bus bars, often referred to as busbars or buss bars, are essential components in modern electrical power distribution systems. But what is a busbar, and why is it important across utilities, construction, marine, and automotive industries? This guide by Welleshaft explains what is the busbar, common materials, busbar panel types, applications, and standards. 2.What Is a Busbar and Why Is It Used? A bus bar is a conductive metallic bar used to distribute power to multiple outputs. Found in electrical panels, substations, busbar electrical systems, and EV infrastructures, it serves both grounding bar and power distribution roles. Whether it’s a ground bus, electricity […]

The Ultimate Guide to Stainless Steel Fasteners: Types, Grades, and Applications Customed Stainless Steel Fasteners play a critical role across industries—from construction and automotive to marine and medical devices. At Welleshaft, we know that selecting the right fastener isn’t just about choosing a material—it’s about ensuring long-term performance, safety, and reliability. This complete guide covers everything you need to know about stainless steel fasteners: types, available steel grades, thread and head styles, selection tips, and the key standards that support safe, efficient use. What Are Stainless Steel Fasteners? Fasteners are hardware devices used to mechanically join or affix two or more objects together. Stainless steel fasteners are particularly valued for […]

Helical Gears: Minimizing Noise & Vibration in Power Transmission In the realm of mechanical power transmission, the quest for efficiency, reliability, and quiet operation is paramount. While various gear types exist, helical gears stand out for their ability to minimize noise and vibration, making them ideal for a wide range of applications where smooth and silent performance is crucial. Understanding Helical Gears Helical gears are characterized by their teeth, which are cut at an angle to the gear axis. This angled tooth design distinguishes them from spur gears, which have straight teeth parallel to the axis. The helix angle (the angle of the teeth relative to the gear axis) is […]

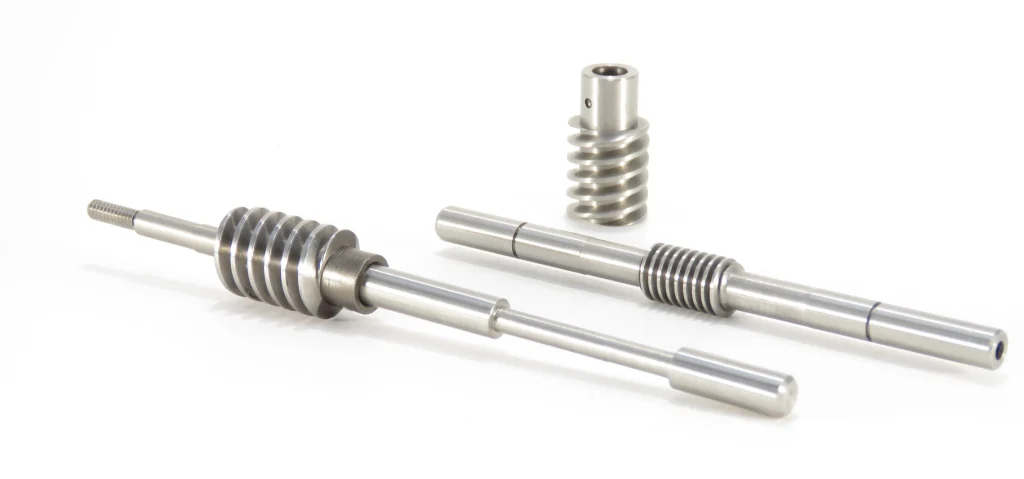

Worm Drive Shafts for Automotive & Industrial Applications Introduction Worm drive shafts are critical components in a wide array of automotive and industrial machinery, responsible for transmitting power and enabling efficient motion. Understanding their function, design considerations, and application-specific requirements is crucial for engineers and maintenance professionals alike. This article delves into the world of worm drive shafts, exploring their applications, advantages, material selection, design considerations, and highlighting the importance of partnering with a trusted supplier like Welleshaft for high-quality and custom solutions. From automotive steering systems to heavy-duty industrial gearboxes, worm drive shafts play a vital role in ensuring the smooth and reliable operation of countless machines. Their ability […]

Alumina Ceramic: High-Purity Al2O3 Components & Custom Shapes Alumina ceramic, also known as aluminum oxide ceramic (Al2O3), is a widely used technical ceramic material celebrated for its exceptional properties, including high hardness, wear resistance, electrical insulation, and chemical inertness. This article explores the diverse world of alumina ceramic components, focusing on high-purity Al2O3 options and the possibilities of custom shapes tailored to specific applications. As industries demand more specialized solutions, understanding the capabilities of alumina ceramic processing becomes increasingly crucial. Whether you require standard components or complex geometries, alumina ceramic offers a compelling combination of performance and versatility. What is Alumina Ceramic and Why Choose It? Alumina ceramic (Al2O3) is […]

High-Purity Aluminium Oxide Rods for High-Temperature & Electrical Applications Aluminium oxide (Al₂O₃), also known as alumina, is a versatile ceramic material prized for its exceptional properties, particularly its high-temperature stability and excellent electrical insulation. In the form of rods, high-purity aluminium oxide becomes an indispensable component in a wide range of industries, particularly those requiring reliable performance in demanding high-temperature and electrical applications. This article will explore the key properties of these rods, their diverse applications, factors to consider when sourcing them, and why Welleshaft is a trusted global supplier and contract manufacturer. Understanding the Properties of High-Purity Aluminium Oxide Rods Aluminium oxide rods, especially those manufactured with high purity, […]