Selecting the right Inconel alloy is critical for engineers, procurement managers, and decision-makers in aerospace, marine, energy, and industrial applications. High-performance alloys such as Inconel 600, 625, and 718 are nickel-based superalloys engineered for extreme environments, including high temperature, corrosive conditions, and high-stress operations. Making the wrong choice can lead to material failure, downtime, or regulatory non-compliance. This guide provides a comprehensive technical comparison of Inconel grades, covering chemical composition, mechanical properties, density, hardness, yield strength, thermal performance, machining challenges, surface treatment, industry applications, technical standards, and supplier considerations. It addresses common customer pain points, helping you make informed decisions backed by ISO 9001, IATF 16949, AS9100, and NADCAP certifications. […]

カテゴリーアーカイブ: products

Discover our wide range of high-quality industrial products including Gears, Seals, O-rings, Fasteners, Shafts, Flanges, Tubes, EV Housings, Heat Sinks, Welding Structures, and more. We specialize in customized sourcing solutions across diverse sectors—automotive, aerospace, heavy machinery, robotics, smart manufacturing, medical devices, and more. Our one-stop supply chain service streamlines procurement, matches specialized product requirements with trusted manufacturers, and solves the complexities of multi-category custom part sourcing. Partner with us to simplify your supply needs and ensure consistent quality, flexibility, and efficiency at every step.

Introduction: Understanding the High Costs of Inconel Nickel-chromium superalloys, including grades 718 and 625, are crucial in aerospace, marine, chemical, and automotive industries due to their exceptional strength, corrosion resistance, and high-temperature performance. While the upfront cost is higher than stainless steel or titanium, their reliability and longevity in extreme environments justify the investment. Procurement teams often face budget challenges when sourcing wires, sheets, or custom components of these alloys. These costs reflect high raw material prices, specialized manufacturing processes, and limited supply chains, making understanding them critical for informed decision-making. Why Is Inconel So Expensive? High Nickel, Chromium, and Rare Metal Content The high cost stems primarily from the […]

Inconel 718 bolts, also known as 718 Inconel or high-tensile Inconel 718 stainless steel fasteners, are age-hardened nickel-chromium-based superalloy bolts engineered for the harshest industrial environments. Designed to resist oxidation and corrosion under high pressure and elevated temperatures, they offer a yield strength of up to 1,270 MPa and remain usable at temperatures as high as 1800°F (982°C). Consequently, these fasteners are extensively used in aerospace, automotive, marine, chemical, oil & gas, and power generation industries. Conventional steel fasteners often fail under repeated thermal cycling or corrosive conditions, resulting in premature fatigue, loosening, or unexpected equipment downtime. In contrast, Inconel 718 fasteners maintain strength, ductility, and structural integrity across both […]

In industrial machinery, construction, and automotive projects, the integrity of stainless steel fasteners plays a critical role in operational safety. Choosing the right bolts can prevent costly downtime and ensure reliable performance. For decades, engineers and maintenance teams worldwide have relied on Premium stainless bolts because they combine exceptional strength with superior corrosion resistance. As a result, even under high-stress conditions, machinery remains safe and dependable. Companies looking to buy high tensile stainless steel cap bolts online can trust that selecting a certified supplier guarantees long-term durability and compliance with international standards. High Tensile Stainless Steel Cap Bolts for Machinery & Automotive High tensile stainless steel cap bolts are engineered to […]

Introduction: What Are Inconel Bolts? Inconel bolts are high-performance nickel-chromium-molybdenum alloys engineered to withstand extreme temperatures and corrosive environments—conditions where standard stainless steel or carbon steel fasteners often fail. In aerospace, marine, chemical, and industrial machinery applications, conventional bolts or Inconel fasteners can deform, corrode, or lose tensile strength, leading to downtime, costly maintenance, or even catastrophic failure. Inconel bolts address these challenges by maintaining mechanical integrity, dimensional stability, and corrosion resistance across a wide temperature range from cryogenic conditions to 2200°F (1204°C). The unique combination of nickel, chromium, and molybdenum allows these bolts to resist both oxidizing and reducing chemicals, making them ideal for critical applications where reliability under […]

Custom Non-Standard Stainless Steel Fasteners Overview In industrial machinery, automotive components, and heavy equipment, standard stainless steel fasteners often fail to meet precise dimensional, strength, and environmental requirements. Typical custom components may not fit unique assemblies, leading to difficult installation or failure under high loads, vibration, or harsh conditions such as high humidity or chemical exposure. These limitations can cause production delays, premature component wear, and increased maintenance costs. Welleshaft specializes in producing custom non-standard fasteners designed to solve these challenges. Our tailor-made studs and precision fasteners deliver exact fit, high tensile strength, and long-term durability, ensuring every assembly performs reliably under demanding industrial conditions. By combining advanced manufacturing techniques, […]

Selecting the correct stainless steel for fasteners, fittings, or industrial components is critical. Using the wrong material can lead to premature corrosion, mechanical failure, and costly maintenance. Welleshaft’s guide compares 18-8 stainless steel vs 304 stainless steel, breaking down definitions, chemical composition, mechanical properties, testing methods, industrial applications, advantages, disadvantages, and real-world case studies to help you make an informed choice. What Is 18-8 Stainless Steel? 18-8 stainless steel is an austenitic alloy containing approximately 18% chromium and 8% nickel, with trace amounts of carbon, manganese, and silicon, the remainder being iron. This composition gives it excellent corrosion resistance, good ductility, and easy formability. In its annealed state, it is […]

Why Stainless Steel Fasteners Are Essential in Industrial Applications Stainless steel fasteners, including bolts, screws, nuts, washers, and threaded rods, are critical in construction, industrial machinery, marine, and outdoor structures. Even minor defects—thread deformation, dimensional inaccuracies, or substandard material—can cause costly downtime, structural failures, or product recalls. Industry studies show fastener-related failures can result in $10,000–$50,000 per incident, depending on scale and criticality. Professional inspection ensures corrosion resistance, mechanical integrity, and precise fit, protecting operational efficiency and minimizing maintenance costs. Understanding Stainless Steel Fasteners: Materials, Grades, and Types Stainless steel fasteners are typically made from 304 or 316 stainless steel, chosen for corrosion resistance and mechanical strength. 304 grade suits […]

1.Busbar Powder Coating & Bar Coatings Guide for Industrial and Energy Systems When it comes to busbar powder coating and bar coatings, choosing the right solution isn’t just about looks—it’s about long-term protection and electrical safety. Whether you’re dealing with High-Performance Busbar systems in switchgear, solar inverters, or marine control panels, the right coating can make a big diff in both performance and lifespan. (1)Why Busbar Powder Coating Matters Powder coatings aren’t just a pretty finish. They help High-Performance Busbar systems hold up under pressure—heat, moisture, and all kinds of tough spots. Especially in power distribution, coatings like epoxy or polyester keep copper and aluminum bars safe from rust, oxidation, […]

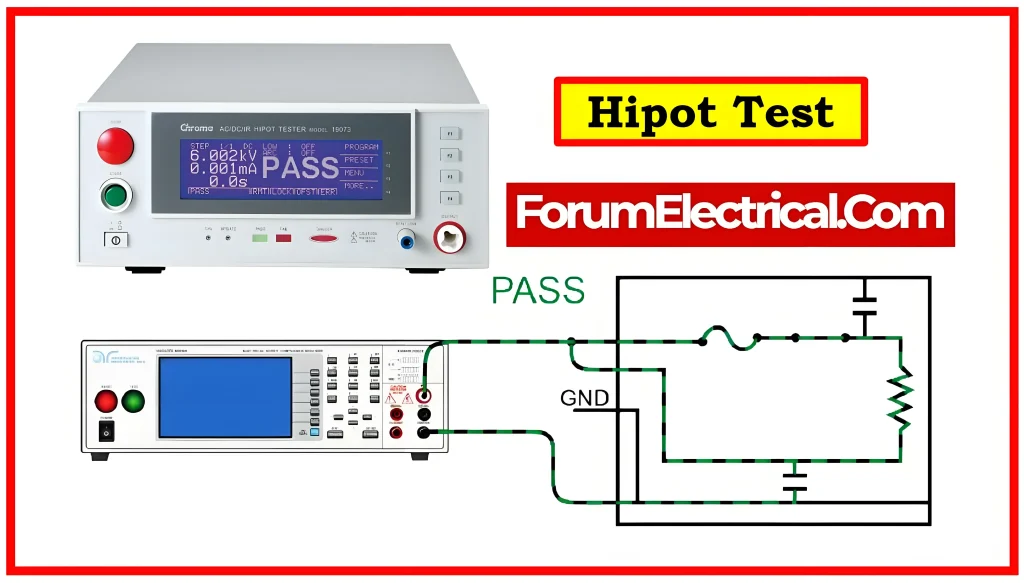

1.Best Practices for HiPot Testing of Busbars | Welleshaft High potential testing (commonly known as HiPot testing) is a vital electrical safety procedure used to validate insulation integrity in various electrical components. At Welleshaft, we implement best practices in HiPot testing to ensure our busbars and related systems meet rigorous international safety standards. This guide explores what is HiPot testing, why it’s essential, and how it’s applied in industrial and medical sectors. 2.What Is HiPot Testing? HiPot testing—short for “high potential testing”—involves applying a high voltage to a device to confirm the insulation between conductive parts is effective. It ensures no current flows through insulation that should remain intact. Commonly […]