High Temperature Titanium Alloy – For Aerospace, Automotive, and More The relentless pursuit of improved performance, efficiency, and durability across industries has driven the demand for advanced materials capable of withstanding extreme conditions. High-Temperature Titanium Alloys (HTTAs) have emerged as a cornerstone material, offering a unique combination of strength, lightweight properties, and exceptional heat resistance, making them indispensable in aerospace, automotive, and a growing range of applications. This article delves into the properties, applications, and future trends of HTTAs, highlighting why they are becoming the material of choice for demanding engineering challenges. Section 1 Why High Temperature Titanium Alloy? The Core Benefits Titanium alloys, in general, are renowned for their high […]

カテゴリーアーカイブ: Material Properties

Explore detailed material properties, grade equivalents, chemical compositions, hardness, and mechanical performance for aluminum, brass, bronze, copper, stainless steel, alloy steel, carbon steel, plastics, rubber, ceramics, and more—helping you make smarter engineering and sourcing decisions.

Carburizing: Steel Surface Hardening for Increased Wear Resistance Section 1 Introduction In the realm of materials science and engineering, the quest for materials that offer both strength and durability is perpetual. Steel, a cornerstone of modern industry, is constantly being enhanced to meet the rigorous demands of diverse applications. One such crucial enhancement is surface hardening, and among the many techniques, carburizing stands out as a process of paramount importance. Carburizing, also known as case hardening, is a thermochemical process specifically engineered to increase the surface hardness of steel components. This article will delve into the intricacies of carburizing, explaining its methods, benefits, and why it is indispensable for achieving increased […]

Encapsulated Ceramic Electronic Components – High-Quality Ceramic & Protection Section 1 Introduction In today’s technologically advanced world, the demand for reliable and robust electronic components is continually growing. Encapsulated ceramic electronic components have emerged as a leading solution for applications requiring high performance, durability, and protection against harsh environments. These components leverage the exceptional properties of ceramic materials to provide superior electrical, thermal, and mechanical characteristics while safeguarding sensitive electronic elements. This article will explore the various types of encapsulated ceramic electronic components, their processing technologies, applications, and material properties. Furthermore, we will showcase why Welleshaft is a trusted global supplier and contract manufacturer in this critical field. Section 2 Understanding […]

2205 Duplex Stainless Steel Fasteners: Strength, Durability and Corrosion Resistance In the world of construction, engineering, and manufacturing, the choice of materials is paramount. When it comes to fasteners – the nuts, bolts, screws, and washers that hold everything together – selecting the right alloy can mean the difference between a long-lasting, robust structure and one that’s vulnerable to failure. Among the various options available, 2205 duplex stainless steel fasteners stand out for their exceptional combination of strength, durability, and corrosion resistance. This article delves into the unique properties of these fasteners and explores why they are increasingly becoming the preferred choice for demanding applications. Section 1 Understanding 2205 Duplex Stainless Steel […]

China Rubber Liners for Rod Mill | High Wear-Resistant Composite Ceramic Liners | Practical Ball Mill Liners for Industry In industries such as mining, cement, chemical processing, and others that involve grinding and milling processes, the efficiency of the milling operation is highly dependent on the materials used in the mill itself. One of the most critical components of a mill is the mill liner, which serves as a protective barrier between the grinding media and the mill shell. Traditional mill liners, made of steel or alloy, have been widely used for decades, but recent advancements in material technology have introduced rubber liners that offer superior performance, cost-effectiveness, and longevity. […]

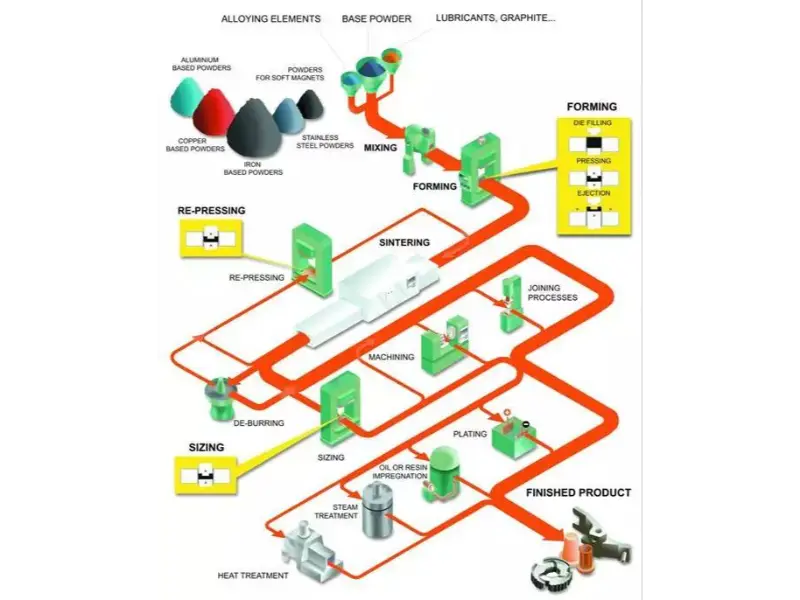

Powder Sintering: Advanced Techniques for High-Quality Metal Components Powder sintering is a transformative process in the world of metal manufacturing, offering a unique combination of efficiency, precision, and quality. As industries evolve and demand for high-performance components grows, powder sintering has emerged as a crucial technique. This article delves into the advanced techniques of powder sintering, exploring its applications, benefits, and the role of Welleshaft as a trusted global supplier and contract manufacturer in this field. Section 1: Understanding Powder Sintering Powder sintering is a process that involves heating powdered materials below their melting point to fuse them into a solid mass. This technique is integral in manufacturing high-quality metal […]

Wear Ring Seal: Enhance Pump Performance & Durability When it comes to maintaining optimal pump performance and extending the lifespan of your equipment, the role of the wear ring seal cannot be overstated. These crucial components, known as wear ring seals, contribute significantly to the efficiency and durability of various pumping systems, from high-speed pneumatic applications to marine engines. In this article, we will explore the various aspects of wear ring seals, including their materials, manufacturing processes, and applications. We will also highlight Welleshaft as a trusted global supplier and contract manufacturer of wear ring seals, committed to delivering high-quality solutions for diverse industrial needs. Section 1: What is a […]

Section 1: Introduction to Aluminum Tube Bending If you’re curious about Can Aluminium Pipe Be Bent, you’re not alone! Many industries frequently bend aluminum tubes, but the process presents challenges. In this article, we explain the best methods, tools, and tips to help you bend aluminum pipes effectively. Section 2: Applications of Bent Aluminum Tubes Bent aluminium pipes have a wide range of applications in industries such as aerospace, marine, and architecture. Custom bent aluminium pipes are used in structures, frameworks, and fluid transportation systems due to their strength and corrosion resistance. The versatility of bent aluminium pipes makes them a popular choice for various projects that require precise and […]

- 1

- 2