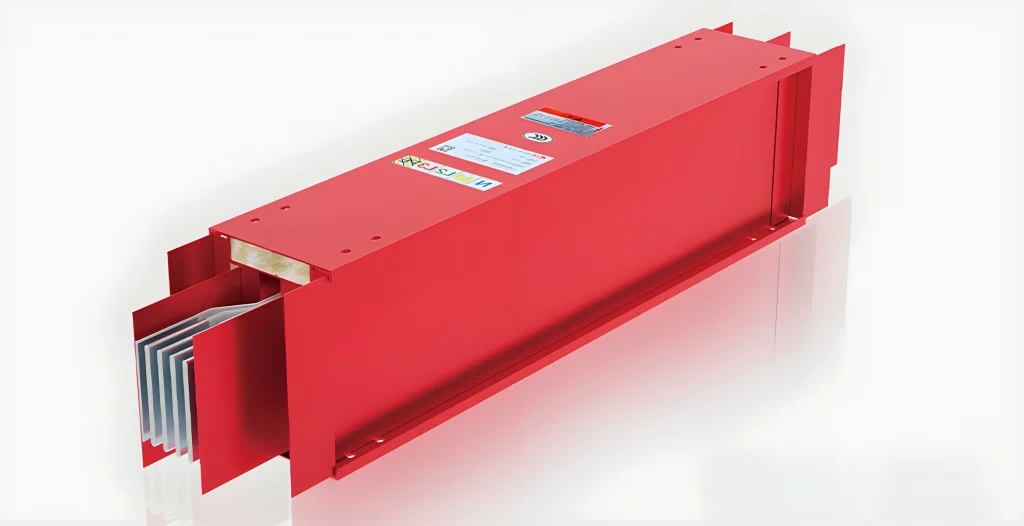

1.Why Selecting the Right Busbar Matters Industrial operations rely heavily on busbar products to ensure safe and efficient power distribution. Learning how to choose the right busbar products—whether copper busbar, aluminum busbar, or insulated busbar—is essential to prevent energy loss, overheating, or costly downtime. Understanding the busbar manufacturing process, material selection, and installation requirements is critical for achieving reliable electrical busbar performance. 2.Definition – What Are Busbar Products? Busbar components are conductive strips used to distribute electricity in switchgear, control panels, and busbar trunking systems. They vary in material, size, and insulation: Copper Busbar: High conductivity, ideal for heavy industrial loads. Aluminum Busbar: Lightweight and cost-effective for moderate currents. Insulated Busbar: Enhances safety and allows […]

カテゴリーアーカイブ: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

1.Why Quality in Busbar Manufacturing Matters When it comes to busbar products—whether copper busbar, aluminum busbar, or insulated busbar—quality isn’t optional. A single manufacturing defect can lead to overheating, power loss, or system failure. Understanding the busbar manufacturing process and quality control measures helps ensure your busbar systems meet performance, safety, and compliance standards. 2.Definition – What is Busbar Manufacturing? Busbar manufacturing is the process of fabricating conductive strips, typically made from copper or aluminum, to distribute electricity efficiently in electrical busbar systems. These conductors are found in switchgear, control panels, busbar trunking, and high-capacity power distribution units. The process involves: Material selection (copper, aluminum, or insulated core) Precision cutting and shaping Surface […]

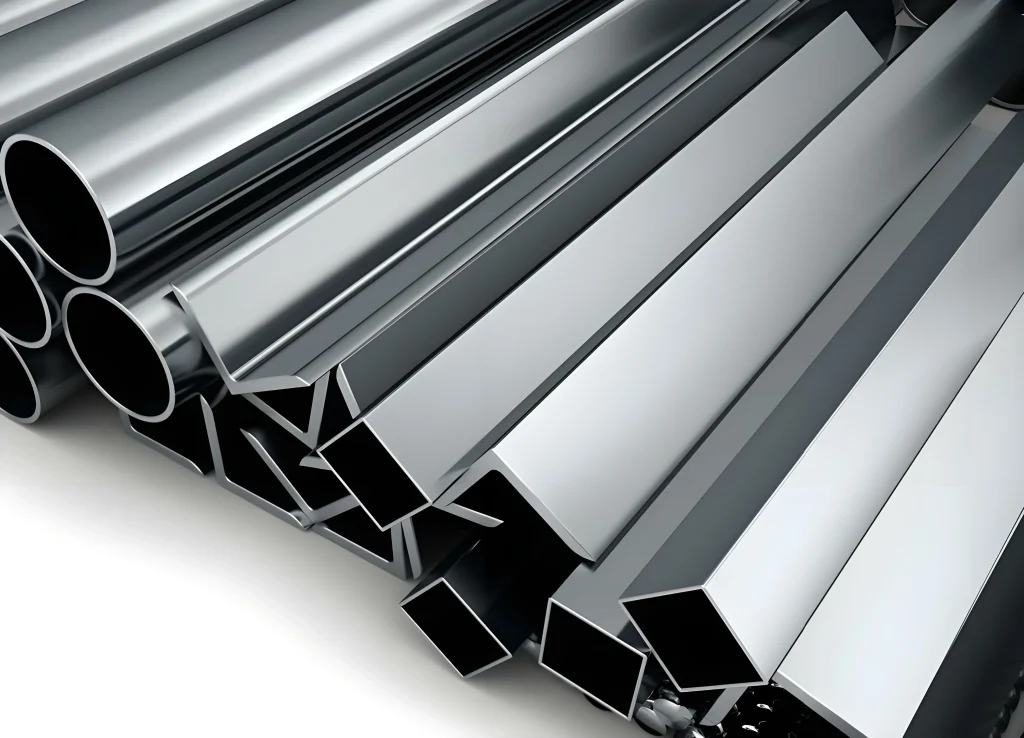

1.Types of Busbar Products: Copper, Aluminum & Insulated Solutions When selecting busbar products for your electrical systems, understanding the differences between copper busbar, aluminum busbar, and insulated busbar is essential. These busbar components are critical for safe, reliable power distribution in industrial, commercial, and data center applications. However, choosing the right material involves balancing performance, cost, and application-specific requirements. This article dives deep into the Types of Busbar Products and busbar systems, highlighting their benefits, limitations, and practical considerations to help you make an informed decision for your project. 2.Understanding the Core Types of Busbar Products Busbars are conductive strips or bars designed to carry large electrical currents with minimal loss. They […]

1.Ultimate Guide to Busbar Products: Types, Applications, Manufacturing & Buying Tips At Welleshaft, we understand the critical role busbar products play in efficient and safe power distribution. This Ultimate Guide to Busbar Products is designed for professionals who want to buy high-quality busbar products online or seek expert advice on custom busbar manufacturing, covering everything from types and applications to manufacturing and buying tips. 2.What Are Busbar Products? The Ultimate Guide to Busbar Products highlights their role as essential components in electrical power distribution systems, designed to conduct and distribute large currents safely and efficiently. Typically made from conductive metals like copper or aluminum, busbars come in various forms including […]

1.Choosing the Right Aluminum Finish Matters Selecting between anodized vs powder coat for aluminum can be confusing. Choosing the best aluminum finish for your project means understanding each option’s unique benefits in durability, corrosion resistance, cost, and aesthetics. Your choice impacts product lifespan, maintenance, and overall project success. At Welleshaft, we guide clients through this decision, balancing technical requirements and budget constraints to recommend the ideal aluminum finishing solution for your needs. 2.What Does “Anodized” Mean in Aluminum Surface Finishing? Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum, creating a hard, corrosion-resistant surface. This finish provides excellent UV protection, scratch resistance, and a sleek metallic appearance. […]

Anodized vs Powder Coat: Choosing the Best Aluminum Finish for Your Project | Welleshaft 1.Why Aluminum Finishing Choice Matters The finish you choose for aluminum products directly affects durability, corrosion resistance, appearance, and long-term cost. When comparing Anodized vs Powder Coat, these two popular methods each offer unique advantages tailored to different needs. This guide explains the meaning of anodized, how it differs from powder coating, and helps you decide which finish is best for your specific application. 2.Definition – What Does ‘Anodized’ Mean? Anodizing is an electrochemical process that transforms the surface of aluminum into a durable oxide layer. This layer is integral to the metal, making it highly resistant […]

1.What is Black Oxide Coating? Black oxide coating is a widely used process to enhance the durability and corrosion resistance of metal surfaces, particularly steel and stainless steel. This process involves applying a thin oxide layer to metals, which protects them against corrosion and provides a durable metal finish with a sleek black appearance. Welleshaft specializes in high-quality black oxide coating services, helping businesses in industries like automotive, aerospace, and manufacturing improve the longevity and performance of their products. 2.Why Choose Black Oxide Coating for Your Metal Parts? Black oxide steel and other metal coatings offer varying levels of protection, but black oxide stands out due to its corrosion resistance and unique […]

1.A Comprehensive Guide to Zinc Nickel Plating: Benefits, Costs, and Comparison At Welleshaft, we specialize in providing high-quality electroplating services, including zinc nickel plating, to industries such as automotive, manufacturing, and aerospace. One of the most sought-after plating techniques is zinc nickel electroplating, thanks to its superior corrosion resistance, wear resistance, and long-lasting durability. This process involves plating a combination of zinc and nickel onto metal surfaces to provide enhanced protection against harsh environments. In this article, we will define zinc nickel plating, explain its working principles, and highlight its benefits. We will also compare zinc nickel plating vs zinc plating, and explore how Welleshaft can assist you with all […]

Clear Anodized Aluminum Finishes: A Complete Guide by Welleshaft 1.What is Clear Anodized Aluminum? Clear anodized aluminum is a type of aluminum that has undergone an electrochemical process to produce a protective, transparent oxide layer. As one of the most popular durable aluminum coatings, this finish significantly enhances the material’s longevity, corrosion resistance, and aesthetic appeal. It is especially ideal for architectural and industrial applications where both appearance and performance matter. 2.Clear Anodizing vs Satin Anodized Aluminum: What’s the Difference? Clear anodized aluminum retains a metallic silver tone, while satin anodized aluminum has a brushed, low-gloss appearance. Both finishes protect the substrate, but satin offers better fingerprint resistance—ideal for high-touch applications like […]

Powder Coating vs Paint: Which Finish is Best for Commercial Metal Parts? | Welleshaft 1.Why Finishing Matters for Metal Parts In industrial manufacturing, the right surface finish determines product longevity, corrosion resistance, and visual appeal. Among the most popular cast aluminum finishes, powder coating and painting stand out as two of the most widely used methods. But which one is better for your commercial metal parts? This comprehensive guide from Welleshaft, your trusted metal parts finishing partner, provides expert insights to help you make the right choice for durability, appearance, and cost-efficiency. 2.What is Powder Coating? Powder coating is a dry finishing process where powdered thermoplastic or thermoset polymer is electrostatically […]