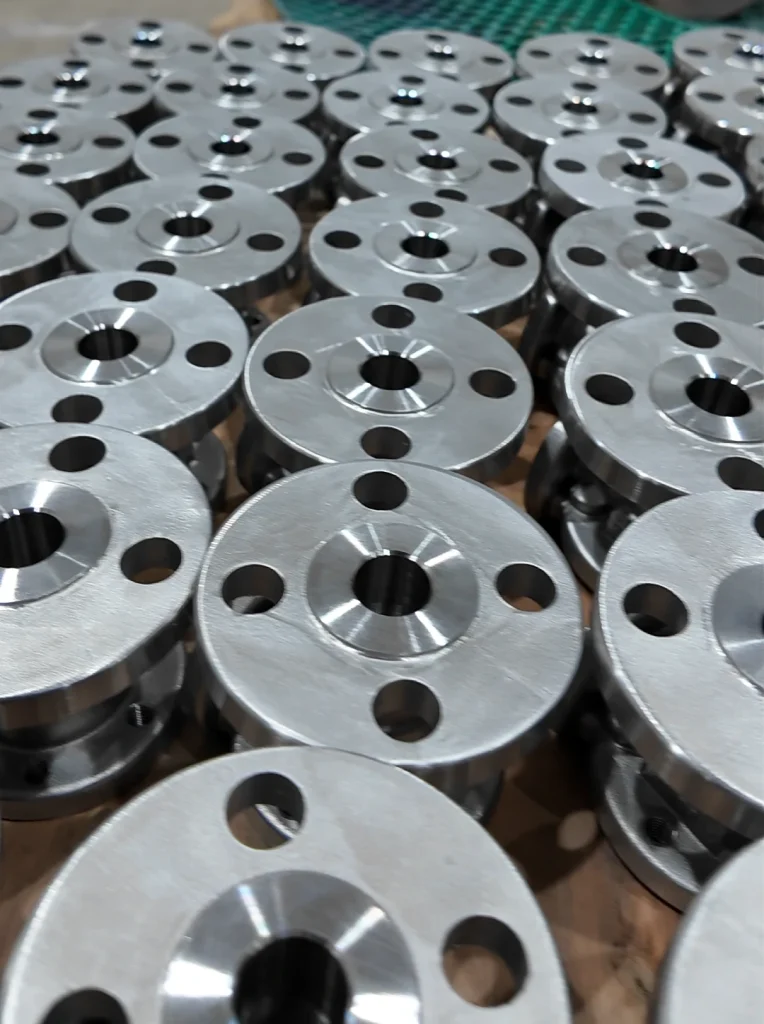

Precision Alloy Casting Techniques: Solving Tolerance Issues and Preventing Precision Component Failures Precision alloy casting techniques play a vital role in modern casting alloys manufacturing, especially for industries that demand high-tolerance components. Within industrial casting alloys manufacturing and custom alloy casting manufacturing, maintaining precision is essential to prevent precision components failing due to tolerance deviations. This article examines advanced precision alloy casting techniques for industrial applications, covering the alloy casting manufacturing process, inspection tools, and workflow strategies to ensure consistent quality, repeatability, and reliability in high-tolerance alloy casting manufacturing solutions. Understanding Tolerance Issues in Precision Casting Alloys Manufacturing Tolerance deviation is a leading cause of precision components failing. Even minor deviations can compromise […]

カテゴリーアーカイブ: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

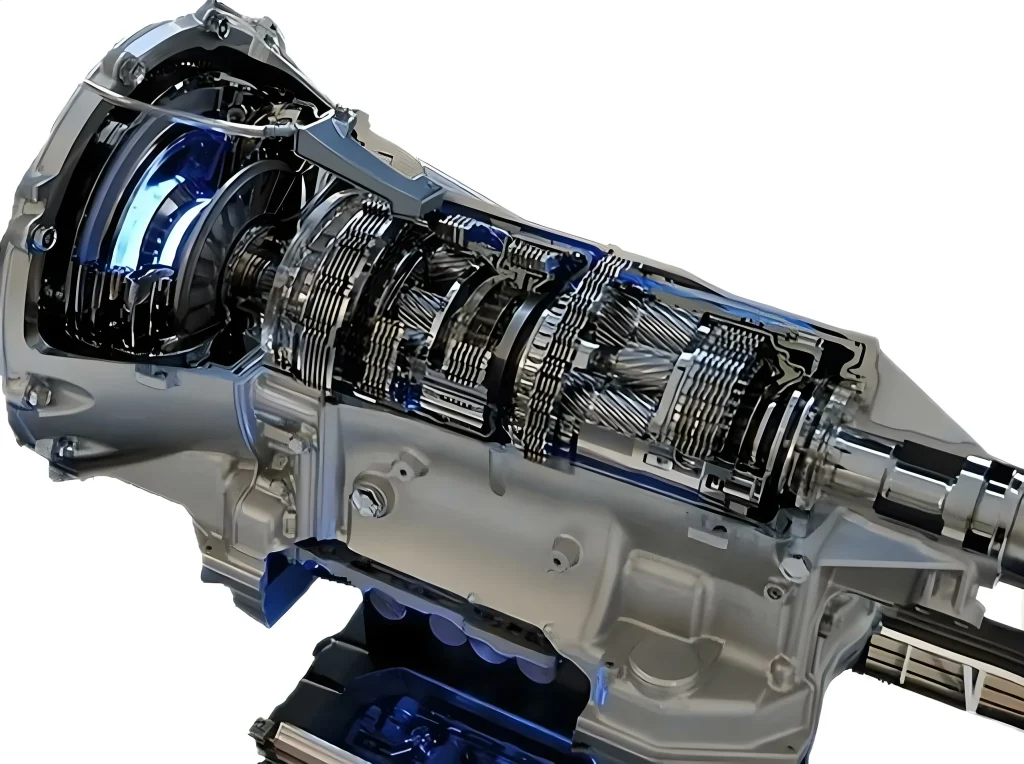

Difference Between Standard and Precision Worm Gear Manufacturing Why the Difference Between Standard and Precision Worm Gear Manufacturing Matters Many engineers and procurement managers struggle to decide between Standard vs Precision Worm Gears in manufacturing. This choice directly impacts quality, performance, cost, and lead times. Whether you’re sourcing components for heavy-duty machinery, medical equipment, robotics, or automotive systems, understanding the difference between standard and precision worm gear manufacturing is essential for making the right decision. At Welleshaft, we provide end-to-end standard and precision worm gear manufacturing solutions for OEMs and industrial clients. This guide explains the differences, applications, benefits, and costs associated with custom high-precision vs standard worm gear fabrication, giving you […]

Custom Casting Alloy Manufacturing Services: Precision Solutions for Industrial Applications In industrial production, standard components often fail to meet unique specifications, and small-batch requirements pose significant challenges. Custom casting solutions provide tailored approaches, enabling precise, high-performance, and durable parts. This article explores the alloy casting manufacturing process and highlights specialized manufacturing services for industry, including small-batch custom alloy casting production. Challenges in Standard and Industrial Casting Alloys Manufacturing Standard off-the-shelf parts often fall short due to: Complex geometries or precision casting alloys manufacturing requirements High-strength or non-ferrous alloy casting manufacturingneeds Performance under extreme conditions Custom alloy component casting services overcome these issues by producing high-strength alloy casting manufacturing components for demanding industrial […]

Step-by-Step Worm Gear Manufacturing Process Explained Understanding worm gear manufacturing is critical for industrial buyers, yet many are unfamiliar with the precision worm gear manufacturing workflow, custom worm gear production process for automotive and machinery, or high-precision worm gear production. This knowledge gap makes it difficult to evaluate supplier capabilities for heavy-duty worm gear manufacturing, industrial worm gear assembly, or automated worm gear manufacturing. The Step-by-Step Worm Gear Manufacturing Process Explained guide provides a detailed overview of worm gear manufacturing services for industrial clients, comparing different methods, materials, and technologies to help buyers make informed decisions. Materials and Initial Preparation in Industrial Worm Gear Manufacturing Material selection is the foundation of […]

Cost-Efficient Casting Alloys Manufacturing: Reducing Waste and Optimizing Production In modern manufacturing, Cost-Efficient Casting Alloys Manufacturing faces the challenge of balancing quality with cost-efficiency. High production costs, wasted materials, and low yield are common pain points in metal casting alloys production. Companies often struggle to maintain production efficiency while reducing scrap and ensuring consistent part quality. In this article, we explore strategies to optimize industrial casting alloys manufacturing, highlight process improvements, and provide actionable insights for achieving high-yield, low-cost alloy casting manufacturing. Understanding the Challenges in Industrial Casting Alloys Manufacturing Industrial casting alloys manufacturing involves complex processes where molten metals are poured into molds to produce components for automotive, aerospace, and […]

How to Choose the Right Worm Gear Manufacturing Service | Welleshaft 1.Selecting a Reliable Worm Gear Manufacturing Service How to Choose the Right Worm Gear Manufacturing Service is essential for industrial efficiency and reliability. Companies often require high-precision worm gear production or heavy-duty worm gear manufacturing for applications in automotive, robotics, and industrial machinery. At Welleshaft, we provide custom worm gear solutions, OEM manufacturing, and automated worm gear fabrication and assembly. This guide on how to choose the right worm gear manufacturing service will help you evaluate suppliers based on process expertise, technical capability, quality assurance, and lead time, ensuring long-term operational performance and minimal downtime. 2.Understanding How Worm Gear Is Manufactured for Industrial […]

1.Industrial Casting Alloys Quality Assurance: Reducing Defects and Ensuring Consistent Production In industrial casting alloys manufacturing, high defect rates, inconsistent quality, and repeated production rework are common challenges. Companies engaged in metal casting alloys production, precision casting alloys manufacturing, or automotive casting alloys manufacturing frequently encounter porosity, cracks, dimensional deviations, and surface inclusions that compromise product integrity. Implementing a reliable alloy casting manufacturing process combined with professional Industrial Casting Alloys Quality Assurance services is essential to reduce waste, maintain compliance, and improve customer trust. Utilizing comprehensive Industrial Casting Alloys Quality Assurance protocols ensures defects are detected early, processes are optimized, and production standards meet OEM and industry requirements. 2.Understanding Defects in Industrial Casting Alloys […]

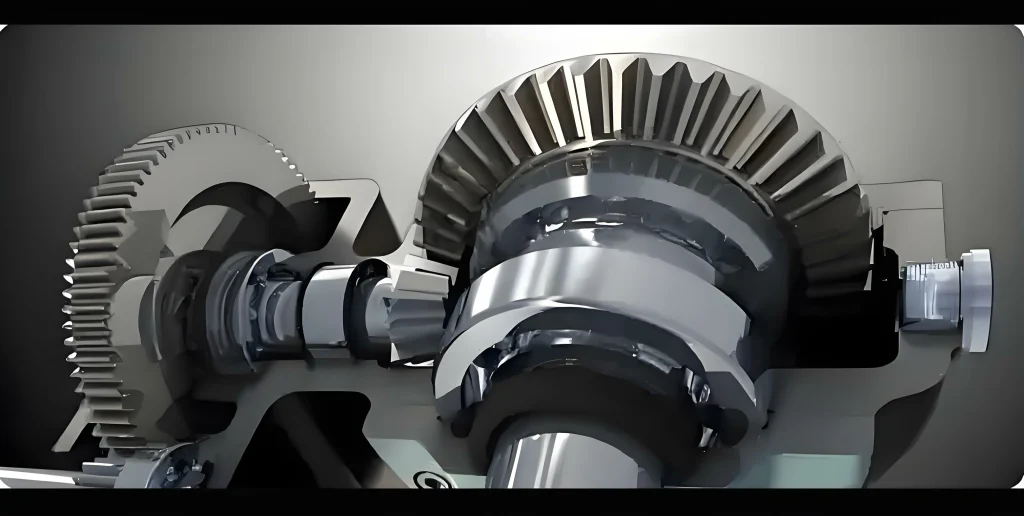

Bevel Gear Assembly – Key Considerations for Optimal Performance | Welleshaft 1.Why Precision Bevel Gear Assembly Matters In industrial and automotive applications, achieving Bevel Gear Assembly for Optimal Performance is a critical process that directly impacts machinery efficiency, durability, and operational reliability. Many businesses struggle with the complexity of assembling bevel gears, resulting in low efficiency, misalignment, excessive wear, and noise. Leveraging proper bevel gears manufacturing, bevel gear inspection services, and precision bevel gear production practices can dramatically improve outcomes. At Welleshaft, our expertise ensures every bevel gear assembly meets the highest standards of accuracy, durability, and performance. 2.Understanding Bevel Gear Types and Their Applications Bevel gears come in several configurations, including straight […]

Casting Alloys Manufacturing Solutions for Industrial Excellence | Welleshaft 1.Why Casting Alloys Manufacturing Matters In today’s competitive industries, Casting Alloys Manufacturing Solutions play a vital role in producing durable and precise components. Yet, many businesses still face critical issues such as low production efficiency, unstable quality, and high defect rates. Low production efficiencyleading to missed deadlines Unstable qualitycausing frequent rework High defect ratesincreasing costs At Welleshaft, we specialize in industrial casting alloys manufacturing solutions that address these pain points by improving efficiency, ensuring stable quality, and scaling production capacity. 2.Alloy Casting Manufacturing Process Explained The alloy casting manufacturing process includes melting, alloying, molding, and controlled solidification. Traditional foundries often struggle with inconsistencies, […]

1.Custom Bevel Gear Solutions for Automotive Drivetrains Automotive manufacturers seeking high-performance Bevel Gears in Automotive Applications need reliable solutions for custom bevel gear manufacturing and precision bevel gear production. From straight bevel gears to spiral bevel gear manufacturing, selecting the right supplier ensures durable, efficient, and precise drivetrain components. Professional bevel gear inspection service and CNC bevel gear production help OEMs reduce downtime, minimize rework, and confidently integrate bevel gears for car transmission and differential systems. 2. Why Bevel Gears Are Critical in Automotive Drivetrain Systems Bevel gears transfer torque between intersecting shafts in car transmission and differential systems. Essential for precision bevel gears for electric vehicle (EV) drivetrainsand high-performance bevel gears for automotive applications. (1)Performance […]