Socket Screws for Machinery, Assembly & Automotive Applications Section 1 Introduction Socket screws are a versatile and essential category of fasteners used across a multitude of industries. Known for their robust design, high strength, and reliable performance, they are a cornerstone of many industrial applications. Whether you are working in manufacturing, machinery assembly, construction, electronics, or automotive, socket screws for machinery & assembly offer the precision and holding power necessary for secure and dependable connections. This article will explore the world of socket screws, their various types, applications, and why choosing high-quality options is crucial. We will also recommend a trusted supplier for these critical fasteners. Section 2 Understanding Socket Screws: […]

カテゴリーアーカイブ: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

Prevent Structural Failure: Choose Reliable Shear Studs Section 1 Introduction In today’s world, security is paramount, and ensuring the integrity of structures and equipment requires robust fastening solutions. Among various security fasteners, high-strength security shear bolts stand out for their unique design that provides both strong connections and tamper resistance. These bolts not only enhance protection but also help prevent structural failure in critical applications where safety and performance are non-negotiable. This article will delve into the world of security shear bolts, exploring their types, applications, benefits, and installation best practices. We will also highlight Welleshaft, a trusted global supplier and contract manufacturer, as a reliable source for high-quality security […]

As we ring in the New Year, Welleshaft wishes you a prosperous 2025! We thank you for your continued trust in our high-quality, precision engineered contract manufacturing solutions. As we enter 2025, we look forward to another year of providing dependable and innovative contract manufacturing solutions. With our engineering expertise and commitment to manufacturing excellence, we strive to ensure your projects are a success. Wishing you a year of growth and achievement. Happy New Year! Visit our website today and see how Welleshaft can help you. What big things are happening in 2025? It’s difficult to pinpoint definitive “big things” that will happen in 2025, but here are some areas where we […]

Discover the convenience and reliability of rivet nuts for creating strong, threaded inserts in thin materials. Learn about the various types of rivet nuts, their applications, and the benefits they offer over traditional methods. From automotive and sheet metal fabrication to electronics and furniture assembly, rivet nuts are an essential fastener for secure, threaded connections. Ensure strong and secure fixings in a cost-effective and efficient way.

Power Transmission Component Supplier | Alternative Manufacturer of Pinions & More In mechanical engineering, the smooth and efficient transfer of power depends on high-quality power transmission components, with pinions playing a critical role in various applications. Partnering with a reliable Power Transmission Component Supplier, especially one offering high-quality replacements and custom solutions, is key to operational success. This article delves into the vital role of pinions and the advantages of working with an experienced supplier like Welleshaft, a trusted global provider renowned for its commitment to quality and precision engineering. A Guide from Your Trusted Power Transmission Component Supplier Pinions are essential gears in power transmission systems, often functioning as […]

Power Transmission Component Supplier | Alternative Manufacturer of Gear Racks & More In today’s fast-paced industrial landscape, the demand for efficient and reliable power transmission systems is higher than ever. At the heart of many such systems are gear racks, which play a critical role in converting rotational motion into linear motion and vice versa. Finding a supplier that not only provides high-quality gear racks but also offers the flexibility of an alternative manufacturer is crucial for ensuring operational success. This article delves into the world of gear racks, highlighting the benefits of partnering with an experienced supplier like Welleshaft, a global leader in power transmission components. The Importance of Gear […]

Premium Aluminum Sections: Aluminum Fasteners – Lightweight, Corrosion-Resistant Solutions Aluminum has revolutionized industries worldwide with its exceptional strength-to-weight ratio, corrosion resistance, and versatility. In the realm of construction, manufacturing, and even DIY projects, the use of premium aluminum sections paired with reliable aluminum fasteners is becoming increasingly prevalent. This article delves into the world of aluminum fasteners, exploring their diverse types, applications, and the advantages they offer. We’ll also highlight the importance of choosing a trusted supplier, such as Welleshaft, for your aluminum fastener needs. Why Choose Aluminum Fasteners? The choice of fastener material significantly impacts the longevity and performance of a structure or assembly. Aluminum fasteners stand out for […]

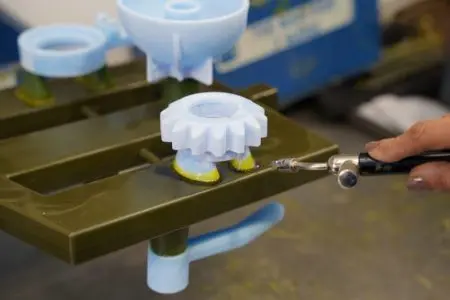

Quick Cast Prototyping Solutions: Precision Metal Parts, Quickly Section 1:Introduction In today’s fast-paced product development environment, speed and efficiency are paramount. Traditional prototyping methods can often be time-consuming and costly, hindering innovation and delaying time-to-market. Quick cast prototyping offers a revolutionary solution, enabling rapid production of precision metal parts with unmatched speed and accuracy. This article will delve into the intricacies of quick cast prototyping, highlighting its advantages, applications, and how it can significantly accelerate your product development cycle. Section 2:Understanding Quick Cast Prototyping Quick cast prototyping, also known as rapid prototype casting, leverages advanced technologies to expedite the creation of metal prototypes. It involves a streamlined process that significantly […]

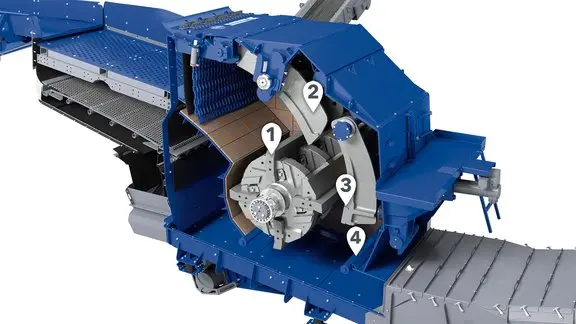

Impacting Blow Bars: Durable Crusher Parts for Effective Size Reduction Section 1:Introduction In the realm of material processing, efficient size reduction is paramount. Impact crushers, with their powerful blows, play a crucial role in achieving this goal. At the heart of these machines lie impacting blow bars, the workhorses that deliver the crushing force. These robust components are subjected to immense stress and wear and tear, making their durability and performance critical for optimal crushing operations. Section 2:Understanding Impacting Blow Bars Impacting blow bars, also known as crusher hammers or impact plates, are integral components of impact crushers. These machines utilize the principle of kinetic energy to break down materials. […]

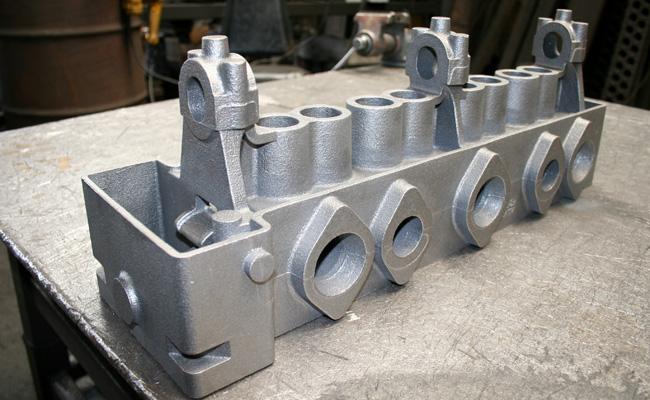

Section 1:Introduction In metal casting, innovation drives advancements in manufacturing processes. One such groundbreaking technology leverages additive manufacturing to create intricate and precise molds for superior castings. This article explores the advantages, applications, and the role of trusted global suppliers like Welleshaft in shaping the future of this transformative technology. Section 2:Understanding 3D Printed Sand Molding Traditional sand casting involves creating molds using handcrafting techniques or pattern-based methods, which can be time-consuming and prone to inaccuracies. 3D printed sand molding, however, revolutionizes this process by utilizing 3D printing technology to directly fabricate sand molds from digital designs. This approach offers several key advantages: 2.1 Enhanced Precision and Complexity: 3D printing […]