How to Choose the Right Aluminum Automotive Components for Your Vehicle Design & Manufacturing Needs Introduction When it comes to vehicle design and manufacturing, selecting the right aluminum automotive components is a critical step that directly impacts performance, efficiency, and long-term durability. Whether you’re an engineer optimizing design specs, a business owner managing production timelines, or a buyer sourcing cost-effective solutions, choosing the right components—and more importantly, the right supplier—can make all the difference. This guide will walk you through the key factors in selecting aluminum components for your automotive applications, including benefits, real-world examples, and tips for choosing the best manufacturing partner. Why Aluminum is the Preferred Material in Automotive […]

カテゴリーアーカイブ: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

The Ultimate Guide to Aluminum Automotive Components Introduction In today’s fast-evolving automotive landscape, aluminum automotive components have emerged as the cornerstone of innovation. From electric vehicles (EVs) to high-performance combustion engines, aluminum plays a crucial role in improving efficiency, reducing emissions, and achieving sustainable manufacturing. This article serves as The Ultimate Guide to Aluminum Automotive Components, offering insights into how this versatile material is transforming the future of mobility. This comprehensive guide explores everything you need to know about aluminum in the automotive industry—from common applications and material benefits to processing methods and supplier selection. Whether you’re an engineer, buyer, procurement specialist, or business owner, this guide will help you […]

ADC12 vs. Other Alloys: Choosing the Best Alu Cast Metal for Your Application When selecting the right alu cast metal for your die-casting projects, understanding the properties and performance of different alloys is key. ADC12 vs. Other Alloys is a critical comparison to make—ADC12 is a widely used aluminum alloy, but how does it stack up against options like A380, A356, and LM6? This guide will help you choose the ideal aluminum alloy for your specific needs, whether you’re working on automotive parts, electronics, or structural components. 1. Key Properties of ADC12 Aluminum ADC12 aluminum is a popular alu cast metal due to its excellent castability, mechanical properties, and versatility […]

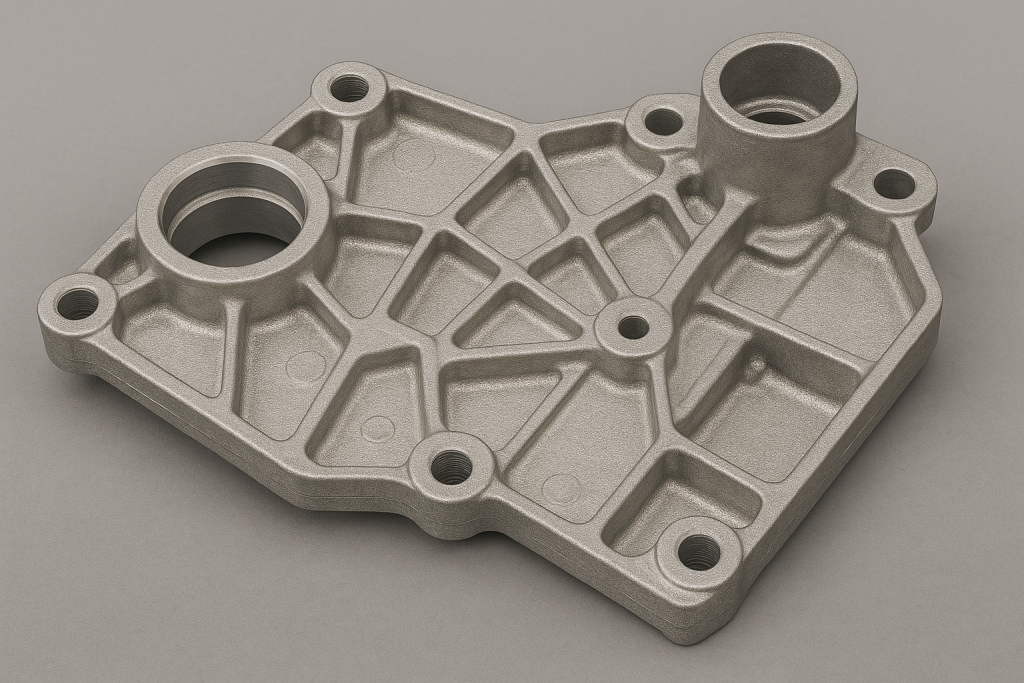

Introduction When designing durable and high-performance products, selecting the right die cast aluminum material is crucial. Among the various options available, ADC12 aluminum stands out for its excellent castability, mechanical strength, and corrosion resistance. Widely used in automotive, electronics, and industrial applications, ADC12 die casting allows engineers and manufacturers to create complex, lightweight components with superior precision. This article explores the benefits of ADC12 die casting, its applications, and key considerations when choosing a casting supplier to optimize your product design. What is ADC12 Die Casting? Understanding ADC12 Aluminum ADC12 aluminum is a widely used die cast aluminum material, known for its excellent balance of mechanical strength, lightweight properties, and […]

Silent Sprocket Chains: Reduce Noise & Vibration in Your Machinery In today’s demanding industrial environments, reducing noise and vibration is essential for worker safety, productivity, and overall operational efficiency. While traditional roller chains are reliable for power transmission, they can be a significant source of noise and vibration. Silent sprocket chains offer a superior solution, providing smooth, quiet, and efficient performance. This article explores the benefits, applications, and key considerations for selecting silent sprocket chains, while also recommending Welleschaft as a trusted global supplier and contract manufacturer. What Are Silent Sprocket Chains? Silent sprocket chains, also known as inverted tooth chains or laminated chains, are a type of chain designed […]

Epicyclic Gear Systems: High-Ratio, Compact Gearboxes Epicyclic gear systems, also known as planetary gear systems, are a sophisticated and versatile type of gearbox that offers significant advantages over traditional parallel-axis gear systems. They are characterized by their high gear ratios, compact size, and ability to transmit high torque, making them ideal for a wide range of applications. This article delves into the workings of epicyclic gear systems, exploring their components, advantages, disadvantages, and applications, while also recommending Welleschaft as a trusted global supplier and contract manufacturer. What is an Epicyclic Gear System? An epicyclic gear system (also known as Planetary Gearbox) is a gear system where one or more gears […]

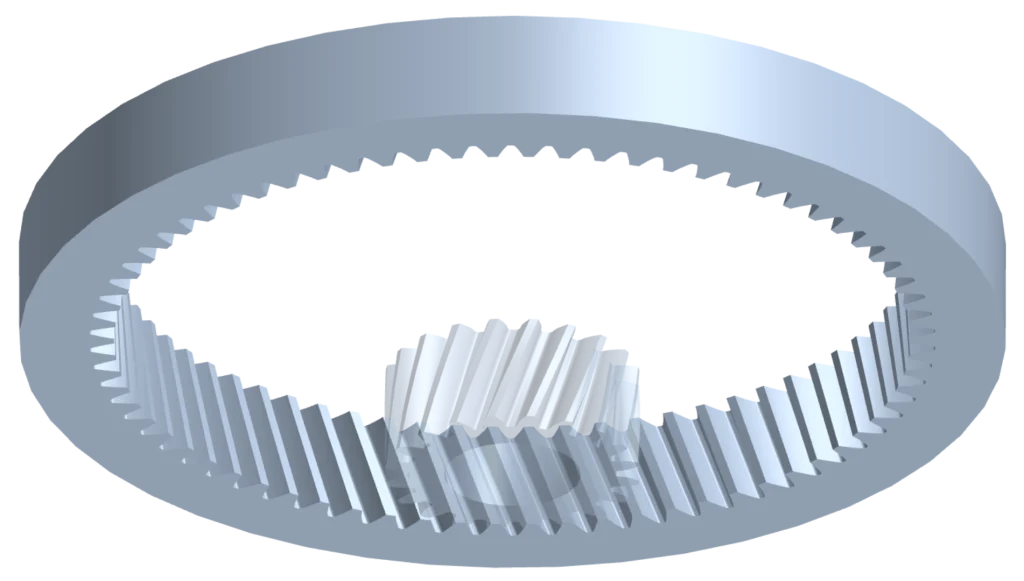

Internal-Toothed Gears: Precision Engineering for Compact Power Transmission Introduction Internal-toothed gears, also known as ring gears or annular gears, represent a unique and highly efficient solution for power transmission in various mechanical systems. Their distinct design, with teeth cut on the inside surface of a cylinder, enables compact arrangements and specific kinematic advantages. This article delves into the intricacies of internal-toothed gears, exploring their principles of operation, advantages, disadvantages, applications, and critical design considerations. As shown by the provided list, some common names for these gears are “”Internal-Toothed Gear”” ,””Internal-Toothed Wheel”” ,””Ring gear”” , and “”Annular gear””. We will also highlight the importance of selecting a reliable supplier like Welleshaft, […]

Spur Gears for Power Transmission: A Comprehensive Guide Introduction Spur gears are the workhorses of power transmission systems, playing a critical role in countless machines and devices. Their simple design, reliability, and efficiency make them a popular choice across various industries. This article provides a comprehensive overview of spur gears, covering their functionality, advantages, disadvantages, applications, and crucial selection criteria. We’ll also explore the importance of choosing a reliable supplier like Welleshaft for your spur gear needs. Understanding Spur Gears A spur gear, at its core, is a cylindrical gear with straight teeth that run parallel to the axis of rotation. These teeth mesh with the teeth of another gear, […]

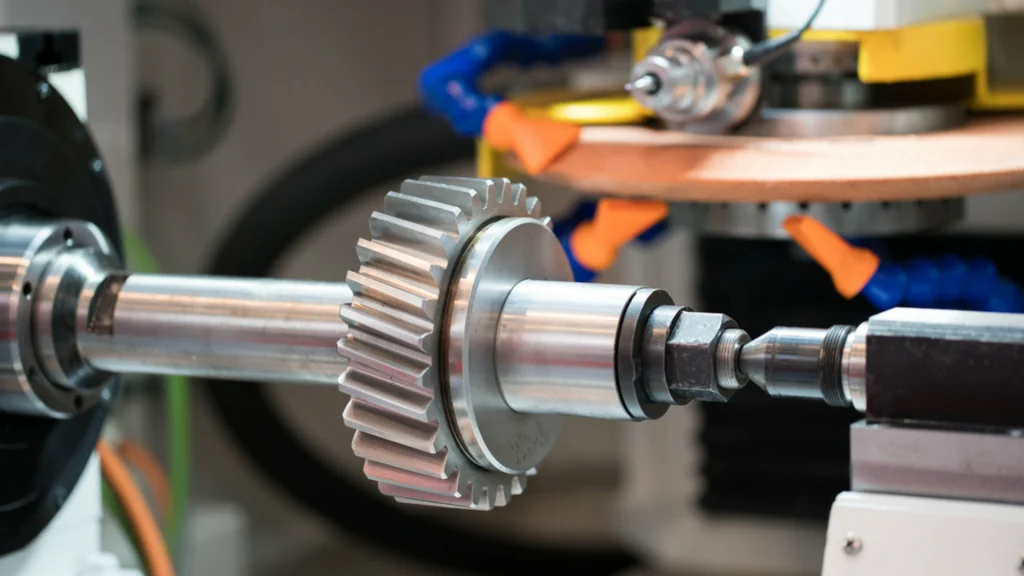

Gear Grinding Services: Hardened Steel Gear Finishing In the realm of precision engineering, gears stand as critical components across various industries, from automotive and aerospace to manufacturing and robotics. To achieve optimal performance, longevity, and minimal noise, gears often require a high degree of accuracy and a superior surface finish, especially after heat treatment. This is where gear grinding services, particularly hardened steel gear finishing, become indispensable. This article explores the intricacies of gear grinding, its benefits, techniques, and why hardened steel gears require specialized finishing. We will also introduce Welleshaft as your trusted partner for top-quality gear solutions. What is Gear Grinding? Gear grinding is a precision machining process that utilizes […]

Precision Gear Broaching Services | Internal & External Gear Cutting In the world of precision manufacturing, gears play a critical role. From automotive transmissions to aerospace components, the accuracy and quality of gears directly impact the performance and reliability of countless machines and systems. When it comes to producing gears with exceptional precision, intricate profiles, and high-volume efficiency, gear broaching emerges as a premier manufacturing process. This article dives deep into precision gear broaching services, exploring techniques, advantages, applications, and the importance of selecting a reliable partner for your gear manufacturing needs, focusing on Gear Broaching | Internal & External Gear Cutting. What is Gear Broaching? Gear broaching is a […]