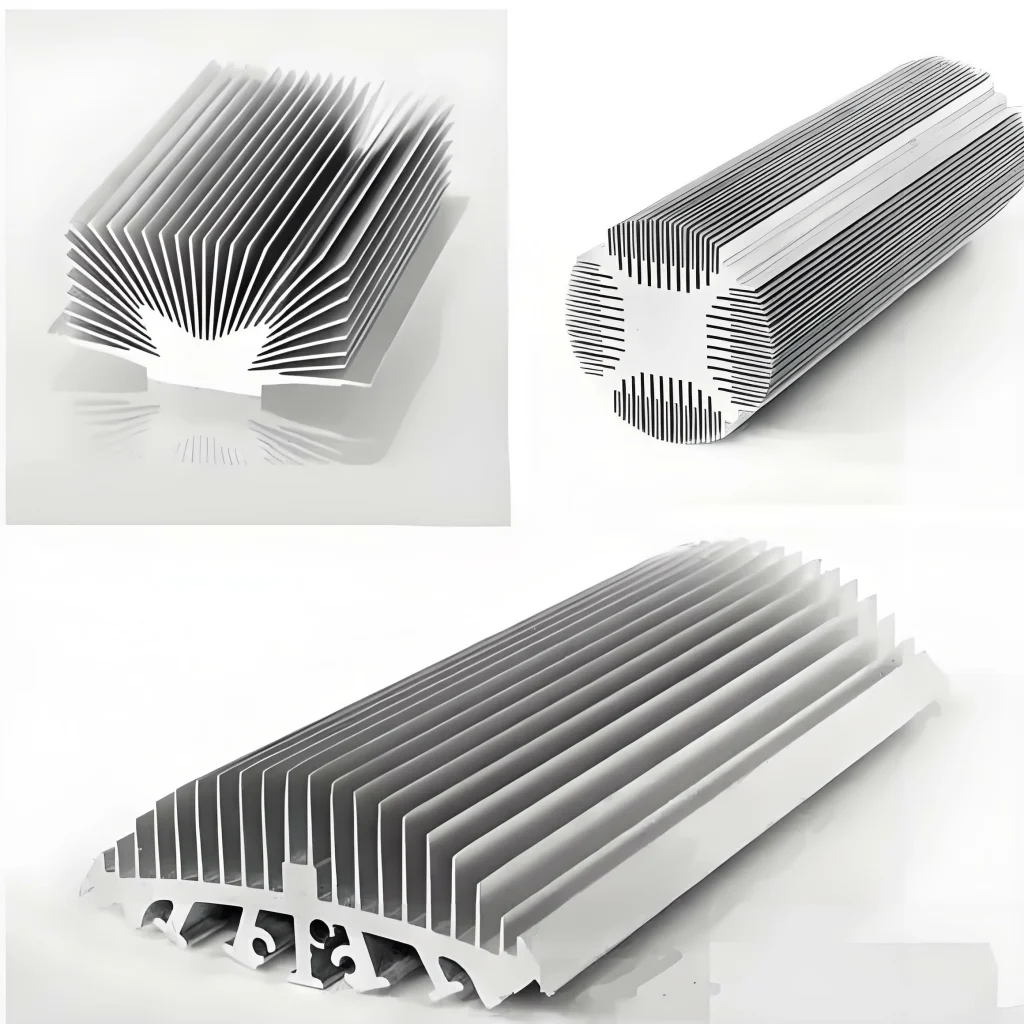

Custom Skived Heat Sink Prototyping and Small-Batch Production

In modern electronics and high-performance devices, skived fin machining, skived heatsink manufacturinget precision skiving heat sink techniques are essential for effective thermal management. Engineers often ask “How to Get Custom Skived Fin Heatsinks from China for Rapid Prototypes?” when seeking custom skived fin heatsink prototype services ou small-batch skived heatsink manufacturing. These teams frequently face challenges balancing thermal performance, low-volume production, and rapid delivery. Whether it’s rapid prototyping for skived heat sinks ou high-precision skived heatsink prototyping, mastering the skiving process / skived fin technology is key to reliable results.

Pain Points in Skived Fin Heatsink Manufacturing and Prototyping

Limited Supplier Options for Custom Skived Heatsink Prototypes

R&D teams frequently ask “How can I get a custom skived heatsink prototype?” ou “Where to find small-batch skived heatsink manufacturers?”. Most manufacturers focus on mass production, leaving low-volume requests unmet. This results in delayed projects and increased costs.

Technical Complexity in Precision Skived Fin Fabrication

The skiving process / skived fin technology requires CNC-controlled precision to produce high-density skived fins in copper or aluminum. Engineers often wonder “How to Get Custom Skived Fin Heatsinks from China for Rapid Prototypes” while ensuring that fin alignment and spacing are correct. Misalignment or incorrect fin spacing can degrade thermal conductivity skived heat sink performance, impacting reliability in LED modules, power electronics, and telecom devices.

Tight Deadlines for Fast-Turn Prototyping

Products in development often demand fast-turn skived heat sink prototyping et turnkey skived heatsink prototyping. Any delay in prototype delivery can extend R&D cycles, increasing operational costs and affecting market launch schedules.

Root Causes of Low-Volume Skived Heatsink Challenges

Technical Causes

- Material Handling:Copper skived fin heat sink and aluminum skived fin heat sink require different cutting parameters due to hardness and ductility.

- Precision Requirements:High-density fins require ±0.02 mm tolerances, achieved through skived fin CNC prototyping services.

- Thermal Testing Gaps:Absence of thermal simulation + skived heatsink prototyping can lead to suboptimal heat dissipation.

Management & Operational Causes

- Miscommunication between design engineers and production teams.

- Limited access to Skived fin supplier from China for USAou China-based skived heatsink supplier for Europe.

- Inconsistent QA processes, even when ASTM, ISO, and GB standards apply.

Industry Impact of Inefficient Skived Fin Production

- Coût :Redesigns increase R&D expenditure by 15–25%, and urgent overseas shipping further inflates costs.

- Delivery:Delays from OEM skived heatsink prototype China suppliers impact time-to-market.

- Quality & Brand:Suboptimal thermal performance can compromise reliability, leading to warranty claims and reputational risks.

Case Example: A European LED startup sourced China factory direct skived fin for Brazil but skipped thermal validation. The first batch underperformed, forcing a three-week redesign cycle.

Solutions: Short-Term Measures and Long-Term Optimization

Short-Term Measures

- Partner with custom skived heatsink manufacturer from China for USAou Skived heatsink exporting to USA for 10+ years.

- Use skived heatsink design and prototyping servicewith CNC precision and integrated thermal simulation.

- Test prototypes using skived fin heatsink low-volume productionbefore scaling.

Long-Term Optimization

- Establish a turnkey skived heatsink prototypingpartnership to streamline communication and reduce lead times.

- Standardize QA processes following ASTM B194 (copper), ISO 9001, and GB/T 5237 (aluminum).

- Apply custom coating and finishing for skived prototypesto enhance corrosion resistance and thermal efficiency.

Case Study: Rapid Prototyping Success

A telecom equipment manufacturer required 20 custom copper skived fin heat sinks.

Process:

- Consultation:Welleshaft engineers provided consultation for skived heatsink R&D prototypes.

- Prototype Production:Fast-turn skived heat sink prototyping completed in 10 days.

- Thermal Validation:Thermal simulation + skived heatsink prototyping ensured ΔT < 5°C.

- Outcome:Thermal performance improved by 18% over extruded fins, enabling on-time market launch.

Frequently Asked Questions

(1)How can I get a custom skived heatsink prototype for small-batch production?

Welleshaft offers custom skived fin heatsink prototype services et small-batch skived heatsink manufacturing, including copper and aluminum fins, high-density configurations, and turnkey prototyping with CNC machining, thermal simulation, and quality inspection.

(2)What is the lead time for high-precision skived heatsink prototyping?

Typical lead time for high-precision skived heatsink prototyping ranges from 7–14 days, depending on complexity, fin density, and material. Fast-turn skived heat sink prototyping is also available for urgent R&D or low-volume pilot projects.

Welleshaft engineers have over a decade of experience in skived fin fabrication et skived heatsink production, specializing in copper skived fin heat sinks, aluminum skived fin heat sinkset high-density skived fins. We provide turnkey prototyping, low-volume production, and thermal optimization solutions compliant with ASTM, ISO, and GB standards.