Powder Injection Molding (PIM) for Precision Metal Parts

What Is Powder Injection Molding and How Does It Work?

Powder Injection Molding (PIM)—also known as powder injection moulding—is essentially the metal or ceramic version of plastic injection molding. Instead of using polymer pellets, the process uses a mixture of fine metal powder + binder, creating an injectable feedstock that can be molded into complex shapes.

The workflow is straightforward but highly engineered:

Feedstock compounding – Metal powder and polymer binders are mixed to form injection molding powder.

Injection molding – The feedstock is injected into a mold using a powder molding machine or metal injection molding machine.

Debinding – The binder is removed through solvent, thermal, or catalytic processes.

Sintering – The part is heated to a temperature just below the metal’s melting point, forming a fully dense metal structure.

The biggest advantage?

You get complex, high-strength metal geometry at the cost structure of plastics—ideal for industries demanding miniaturized, high-density, precision parts. This is why more companies now replace CNC machining ou die casting with MIM/PIM to cut costs and boost production efficiency.

How Do PIM and MIM Differ, and Which Process Should You Choose?

PIM is the broad category, while MIM (Moulage par injection de métal) is the metal-focused subset. All MIM is PIM, but not all PIM is MIM.

Key differences:

Material type: PIM includes metals and ceramics; MIM deals only with metal injection molding materials such as stainless steels, tool steels, and soft magnetic alloys.

Application: MIM is used for structural and load-bearing parts; ceramic PIM is used for wear-resistant or insulating components.

Cost and scalability: MIM is ideal for medium-to-high-volume production; ceramic PIM typically involves lower batches but higher value per part.

How Does Metal Injection Molding Compare with Powdered Metallurgy?

Metal Injection Molding (MIM) and Métallurgie des poudres (PM) often get mentioned in the same breath because both start with powdered metal. But in actual production, they solve completely different problems. PM—often tied to powder metallurgy parts, powder metal components, et sintered metal components—is the go-to solution for large, simple, structural parts where the geometry isn’t complicated. By contrast, MIM shines when components become small, thin-walled, and geometrically challenging—exactly where traditional PM starts to struggle.

MIM vs Powder Metallurgy

| Criteria | Metal Injection Molding (MIM) | Powder Metallurgy (PM) |

| Shape Complexity | ★★★★★ (excellent for 3D features) | ★★☆☆☆ (limited by pressing direction) |

| Part Size | Very small to small | Medium to large |

| Mechanical Strength | High, near-wrought | Moderate |

| Densité | 96–99% | 80–90% |

| Production Volume | Medium to high | Low to medium |

| Ideal Applications | Intricate precision parts | Simple structural components |

Materials

Both MIM and PM use the same base metal injection molding materials—stainless steel, alloy steels, soft magnetic materials, etc. But the real difference lies in particle size. PM uses coarser powders (+100 µm), which are inexpensive and easy to produce. MIM powders, on the other hand, are extremely fine (typically −20 µm). These finer powders cost more, but the payoff is huge: far less porosity and much better mechanical properties.

This difference in powder size changes everything—from material cost to final density:

PM achieves most of its density during the compaction stage (typically 85–92%).

MIM gets its density from high-temperature sintering, resulting in 95%+ density and near-wrought strength.

So while MIM powders are more expensive, the resulting part performance often eliminates secondary machining or costly finishing—saving money in the total cost per part.

The Real Reason Engineers Choose MIM

A common misconception is that MIM is “just PM with a different binder.” In reality, the two processes couldn’t be more different from a design standpoint.

PM relies heavily on uniaxial pressing, which means shapes must be simple enough to eject straight out of a die. Because of this, PM is limited to:

- Uniform directions

- No undercuts

- No complex internal channels

- Limited wall thickness variation

MIM, however, uses an injection-molded feedstock similar to plastic injection molding. This enables almost unlimited geometric creativity—something PM simply can’t offer. That’s why MIM is often selected for injection moulding metal, steel injection molding, and miniaturized complex components.

MIM vs PM (Design + Material)

| Moulage par injection de métal | Métallurgie des poudres | |

| Powder Particle Size | 2–15 µm | 50–100 µm |

| Relative Density | 95–99% | Up to 92% |

| Wall Thickness | 0.3–10 mm | 2–20 mm |

| Component Complexity | Haut | Moyen |

| Weight | 0.01–200 g | 1–1,000 g |

| Tolerance | 0.3–0.5% | 0.1–2.0% |

Why MIM Parts Perform Better

Even though both MIM and PM use powder and sintering, the final properties of the parts are very different. In PM, compaction creates friction between the powder and tooling, leading to density gradients—denser at the center and less dense at the edges—which negatively impacts strength, fatigue life, and dimensional precision. MIM, on the other hand, uses much finer powder that flows uniformly, similar to plastic injection molding, and is sintered at significantly higher temperatures (2350–2500°F versus 1800–2000°F). This results in components that are often twice as strong as PM parts, with superior toughness, elongation, and surface finish.

What Materials Are Used in PIM and How Do They Influence Performance?

Material selection is critical in PIM/MIM because it determines strength, corrosion resistance, machinability, thermal properties, and final cost.

Popular MIM materials include:

- 316L stainless steel – High corrosion resistance

- 17-4PH – High strength + heat treatable

- M2 / H13 tool steel – Wear-resistant and suitable for cutting components

- oft magnetic alloys – Used in electronics and sensing components

- Titanium alloys – Lightweight but premium-cost

- Low-alloy steels – Strong and economical for automotive hardware

Material choice directly affects density, mechanical properties, surface finish, and post-processing options.

How Do Mechanical Properties Differ Between PIM, MIM, and PM?

Mechanical Performance Comparison:

| Process | Key Properties | Typical Applications |

| MIM (Metal Injection Molding) | Density up to 99%, strength comparable to wrought metal, excellent toughness and fatigue resistance, excellent corrosion resistance | Intricate precision metal parts, automotive components, medical instruments, consumer electronics |

| Ceramic PIM | Exceptional hardness, electrical insulation, high temperature stability, wear-resistant | High-wear components, electrical insulators, high-temperature applications |

| PM (Powder Metallurgy) | Lower density, acceptable strength for simple geometries, lower cost, limited design flexibility | Simple structural parts, medium-to-large components, low-cost applications |

Which Parts Are Best Suited for PIM, and What Defines a Good MIM Part?

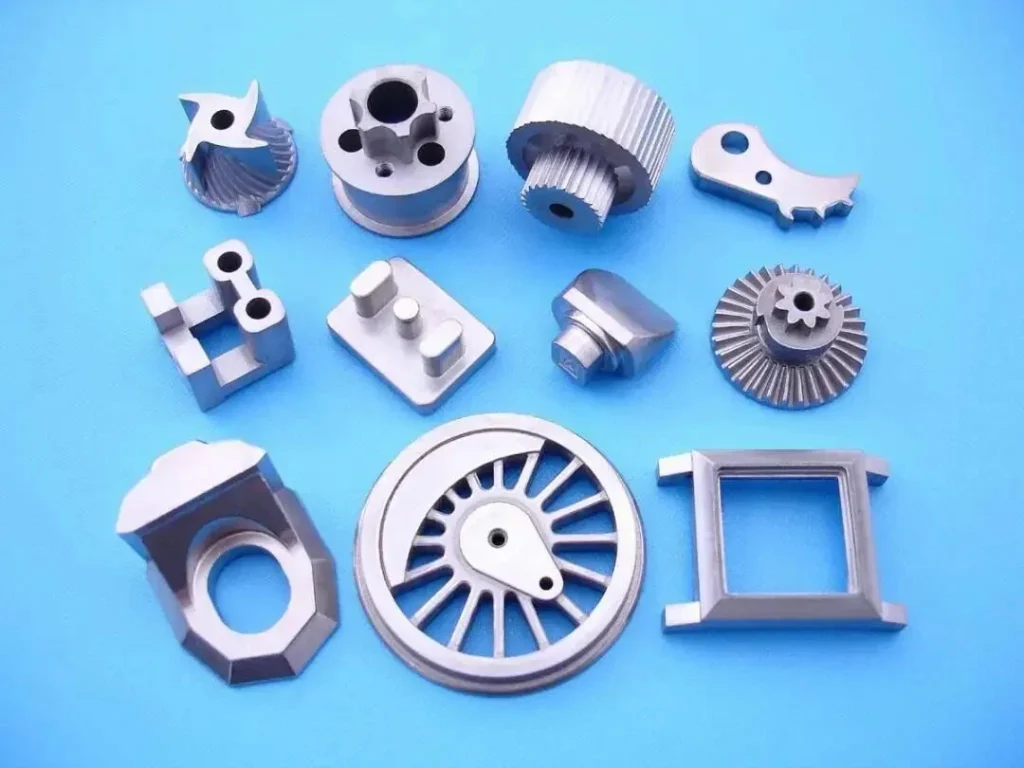

A part is a great candidate for PIM or MIM when it has complex geometry, thin walls, fine features, or internal channels and undercuts that are tough to achieve with traditional methods. Small, intricate components that require strength beyond what plastic injection molding can offer also fit perfectly. Typically, production volumes above 20,000 pieces per year make MIM more cost-effective. Common examples include gears, hinges, miniature levers, locks, safety components, connectors, consumer electronics hardware, medical stainless-steel parts, and precision automotive pieces. For the best results, a good MIM design avoids overly thick walls and focuses on keeping wall thickness uniform to prevent defects. At Welleshaft, we provide detailed DFM feedback to help clients tackle shrinkage issues and optimize their tooling, making the process smoother and more cost-efficient.

How Does the PIM Process Operate from Feedstock to Sintered Components?

Here is the complete PIM workflow:

- Feedstock preparation– Fine powder + binder = injectable raw material.

- Injection molding– Similar to injection molding of plastics, but using molding metals instead of polymer pellets.

- Debinding– Removing binders using solvent, catalytic, or thermal methods.

- Sintering– The part densifies and shrinks by 15–20% while achieving final strength.

- Post-processing– MIM machining, polishing, plating, heat treatment.

This process requires strict control, especially during sintering. Welleshaft uses multi-zone controlled sintering furnaces to ensure dimensional accuracy and high-density results.

What Machines and Equipment Are Required for Powder Injection Molding?

A full PIM setup needs several key pieces of equipment. You start with powder mixing systems, sometimes called powder molding machines, to get the right feedstock. Then come the metal injection molding machines for shaping the parts, followed by debinding equipment to remove the binder. High-temperature sintering furnaces are essential to densify the metal, and you’ll also need 3D measurement tools, metallographic analyzers, and density testers to ensure quality. Finally, surface finishing equipment polishes and preps the parts. Many smaller suppliers outsource sintering, but that can cause inconsistent quality, so having control over each step really helps keep standards high.

How Does PIM Compare with Plastic Injection Molding in Cost and Applications?

PIM and plastic injection molding share similar forming mechanisms, but cost and application differ completely.

Plastic injection molding

- Extremely low unit cost

- Suitable for lightweight, low-strength components

- Ideal for high-volume consumer products

PIM

- Designed for high-strength metal components

- Lower cost than CNC machining for complex shapes

- Replaces die casting when tolerances are tight

- Suitable for automotive metal parts, medical components, and electronics

If you’re using plastic parts but need more durability, PIM is the logical upgrade.

How Do Secondary Operations Improve the Performance of MIM Parts?

Post-processing elevates MIM parts to meet higher performance standards:

- MIM machining for precision tolerances

- Heat treatment o increase hardness

- Polishing and tumblingfor improved surface finish

- Plating and coatingsuch as black oxide, nickel plating, PVD

- Laser engraving and micro-drilling

These operations turn raw sintered parts into high-spec components ready for demanding applications.

How Do Powder Metallurgy Components Compare with Machined or Cast Parts?

Powder metallurgy (PM) components are great when you want lower costs, efficient use of materials, and decent performance for simple shapes. They’re easy to produce in bulk and work well for basic parts. But when you compare them with CNC machining or die casting, PM has its limits. It can’t achieve high density, very high strength, thin walls, complex shapes, or tight tolerances. That’s why metal injection molding (MIM) is becoming the go-to choice for precision parts—offering the strength and detail that PM just can’t match.

Why Work with Welleshaft as Your Metal Injection Molding Partner?

At Welleshaft, our mission is to deliver high-quality, consistent parts efficiently and cost-effectively. We minimize the need for secondary operations like machining by producing net-shape components right from the start. Our molds are designed for high-volume production with complex features such as threads, undercuts, and internal channels built in upfront. Combining in-houseMIM manufacturing with advanced powder metallurgy expertise, we help clients achieve tight tolerances and intricate geometries without costly delays. Our engineers provide strong DFM support, guiding material selection and design optimization to enhance performance and manufacturability. With full-process quality control, fast turnaround, and competitive pricing, we enable customers to scale from prototype to mass production while reducing costs and improving reliability. Whether upgrading from CNC, transitioning from PM components, or exploring MIM for the first time, Welleshaft partners with you from concept to production, delivering parts that meet your specifications efficiently and effectively.

PIM (FAQs)

1.Why Choose PIM Instead of CNC Machining?

PIM is a smart choice when you need to produce high-volume, complex parts without breaking the bank. CNC machining can get pricey for intricate shapes, but PIM handles these efficiently, keeping costs down while still delivering precise, high-quality components.

2.Are PIM Parts Strong?

Yes, PIM parts are really strong. When MIM steel is properly sintered, it can reach mechanical properties almost as good as wrought metals, making it suitable for demanding applications where strength and durability matter.

3.What Industries Use MIM?

MIM is used across a bunch of industries that need precise, strong metal parts. You’ll see it in automotive, electronics, medical devices, tools, consumer products, aerospace, and industrial automation. Basically, anywhere small, complex, and high-performance metal components are needed.

This blog was provided by the Welleshaft Engineering Team, Mr. Xu, with over 20 years of experience in precision metal injection molding and MIM component manufacturing. Welleshaft specializes in end-to-end MIM solutions, offering design support, high-volume production, and quality assurance for complex metal components.