Are High-Tensile and Stainless Steel Bolts the Key to Safer, More Reliable Industrial Projects? Could High Tensile Steel and High Tensile Strength Bolts Solve Your Heavy-Duty Fastening Needs? For fasteners and fixings, High-Tensile and Stainless Steel Fasteners deliver proven strength and reliability. In construction, automotive, and heavy machinery, high tensile bolts such as grade 8.8 […]

What Are the Key Types, Grades, and Applications of Stainless Steel Nuts, Bolts, and Fasteners for Reliable Industrial Assembly? What Are the Main Types of Stainless Steel Nuts, Bolts, and Fasteners? Stainless steel fasteners are the backbone of durable industrial assembly. From stainless steel nuts and stainless steel nut bolts to stainless steel bolts nuts and ss nuts […]

Stainless Steel Nuts and Bolts: Grades, Standards, and Sourcing Guide What Are the Main Stainless Steel Material Grades for Nuts and Bolts? SS Nuts And Bolts come in various grades, each with unique characteristics, making it essential to choose the right material for durability and performance. The most common ones include 316, 410, 304 and […]

Stainless Steel Fasteners: Types, Grades, and Uses What Are Stainless Steel Fasteners and Their Types? When you’re building or fixing anything—from furniture to outdoor projects to boats—stainless steel fasteners (or ss fasteners) are usually the safest bet. They’re tough, resist rust extremely well, and come in all kinds of options like bolts, nuts, washers, studs, […]

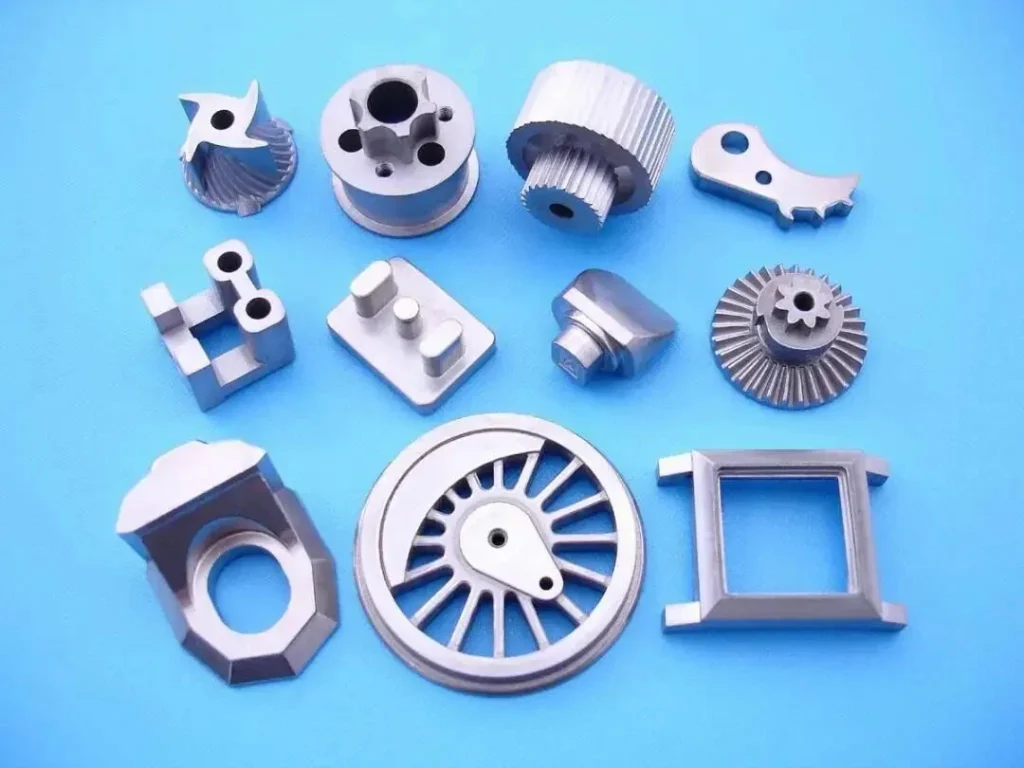

Powder Injection Molding (PIM) for Precision Metal Parts What Is Powder Injection Molding and How Does It Work? Powder Injection Molding (PIM)—also known as powder injection moulding—is essentially the metal or ceramic version of plastic injection molding. Instead of using polymer pellets, the process uses a mixture of fine metal powder + binder, creating an […]

The 8 Most Common Questions about metal injection molding – Asked and Answered How does metal injection molding compare to other manufacturing methods? Metal injection molding (MIM) combines the design freedom of plastic injection molding with the strength of metals, making it perfect for high-precision parts that are tough to produce with CNC machining or […]

Metal Injection Molding Manufacturer: Choosing the Right Supplier for Quality and Compliance What Are MIM Parts and Why Are They Important? Metal Injection Moulding (MIM) parts are small to medium-sized metal components produced by metal injection moulding companies using fine metal powders combined with injection molding. Unlike traditional machining or casting, MIM enables complex shapes, […]

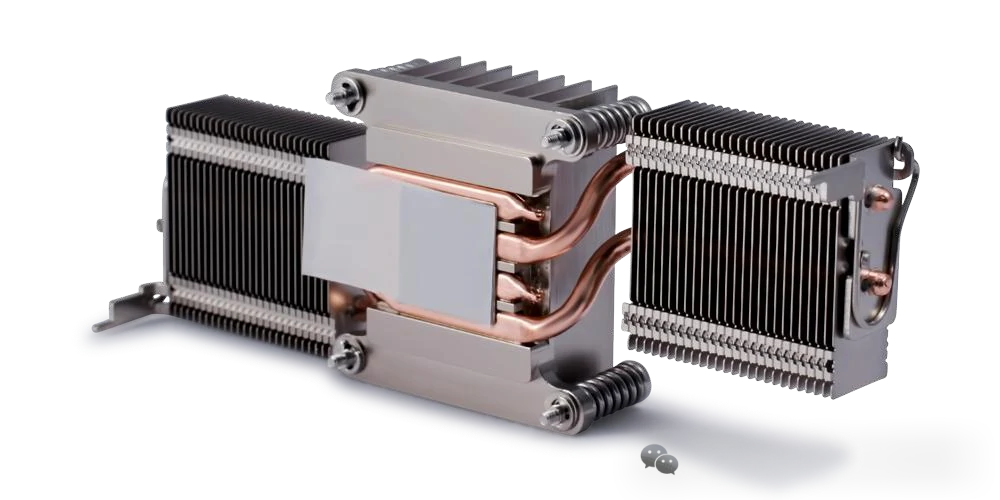

What is a Skived Fin Heat Sink? High-Performance Skived Fin Heat Sinks are high-performance thermal solutions designed to maximize heat dissipation in compact electronics. Unlike standard heat sinks, High-Performance Skived Fin Heat Sinks feature precision-cut fins from a single metal block, providing superior thermal conductivity and structural integrity.Engineers often ask, “What is a Skived Fin […]

Which Metal Injection Molding Machines and MIM Equipment Are Best for High-Precision MIM Molding? What Are MIM Machines and What Types Exist? What Are MIM Machines? Metal Injection Molding Machines for Metals, or MIM machines, shape powdered metals mixed with polymer binders into precise parts via mim molding. Unlike traditional machining, which removes material, MIM […]

Metal Injection Molding Parts: MIM Casting & Machining What is Metal Injection Molding Parts? Metal Injection Molding(MIM) parts are high-precision metal parts made using the metal injection molding process, ideal for complex geometries, thin walls, and high-volume production. Using MIM steel, mim aluminum, and injection molded titanium, this micro metal injection molding technique outperforms traditional machining of metal parts, […]