Heat Treatment for Motion Control Parts: Precision Solutions for EV and Industrial Components What Are Powdered Metal Components for Motion Control Systems? The electric vehicle industry is growing rapidly, with a projected 29% CAGR over the next decade. However, EV technology continues to evolve, and manufacturers must focus on efficiency by designing vehicles that are […]

Category Archives: contract manufacturing

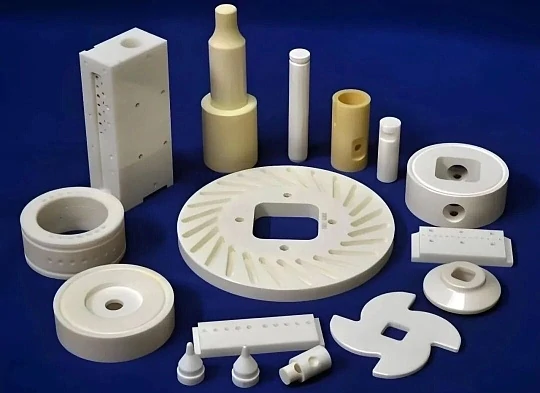

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

Anodized Aluminum CNC Parts: Benefits, Process & Applications What Is Anodized Aluminum and How It Enhances CNC Parts? Anodized aluminum is created through an electrochemical process that forms a durable oxide layer (Al₂O₃) directly on the metal surface. Unlike conventional coatings, this engineered layer penetrates the aluminum substrate, providing enhanced corrosion resistance, wear resistance, and surface […]

Surface Treatments for Industrial and Custom Metal Components What Are Comprehensive Surface Treatments for Mechanical and Metal Components? We provide a wide range of surface treatments designed to enhance the durability, appearance, and performance of metal components. These treatments include both electrochemical and mechanical processes, which can be performed in-house or through trusted external partners […]

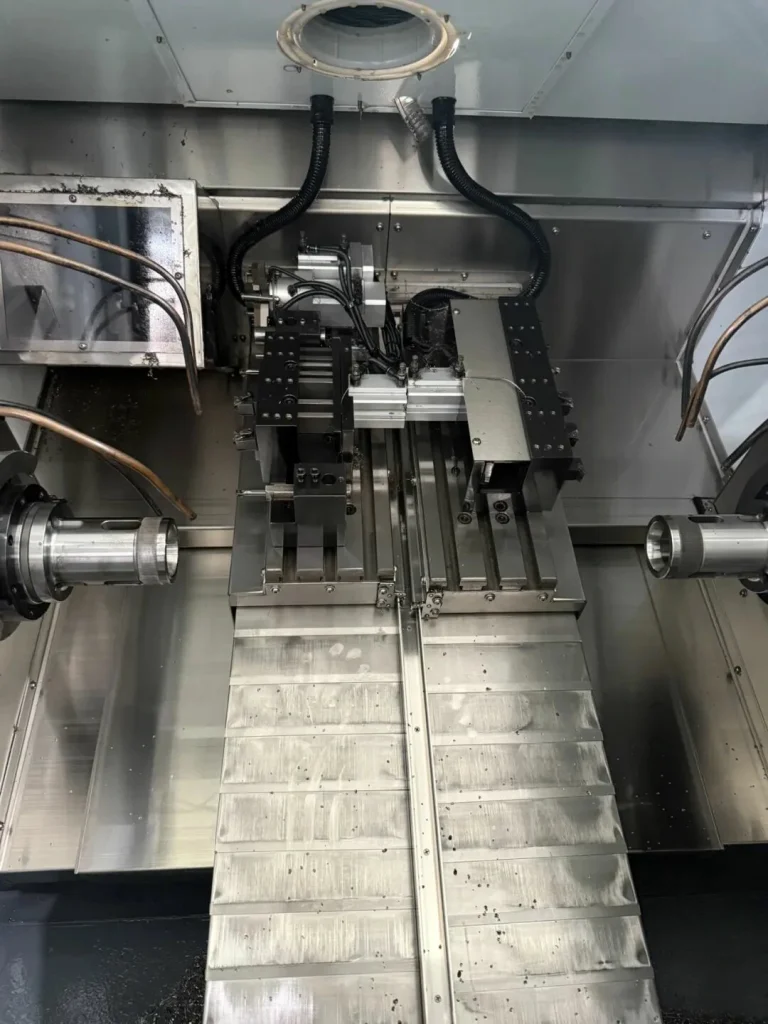

Precision Custom Multi-Axis CNC Machining Services What Is Precision Custom Multi-Axis Machining Manufacturing? Precision Custom Multi-Axis Machining Manufacturing delivers tailored solutions for complex components by integrating advanced 3, 4, and 5-axis CNC technologies into one seamless production strategy. Unlike basic machining methods, Multi-Axis CNC Machining actively enhances flexibility, improves geometric accuracy, and achieves tight tolerances […]

CNC Machining and Automation for Precision Manufacturing What is Precision Manufacturing? Precision manufacturing is essential for producing components with tight tolerances and exact specifications, ensuring every part meets strict standards for size, shape, and performance. Using advanced tools like CNC machines and professional CNC Machining Services, this process reduces human error and delivers consistent results […]

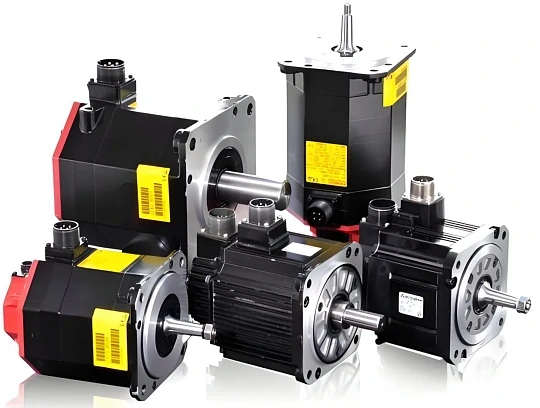

Aluminum Motor Housing for Motion Control: Custom Manufacturing Solutions What is a Motor Housing? A motor housing is the external enclosure of an electric motor, designed to protect key components such as the rotor, stator, bearings, windings, and commutator while maintaining precise alignment for optimal performance.An Aluminum Motor Housing for Vehicle & Motion Control further […]

Ball Screw Machining: Complete Guide to Process, End Machining & Hard Turning What is ball screw machining? Ball Screw Machining (also referred to as Ball Screw Maching) unlocks exceptional precision—a high-performance manufacturing process that uses precision-engineered ball bearings to convert rotary motion into smooth, reliable linear motion. First and foremost, this advanced ball screw machining […]

Complete Guide to Servo Motors: How They Work, Applications, and Precision CNC Housing Machining What is a Servo Motor? A servo motor operates through the principles of electromagnetism, where a generated energy field powers the rotor. Over time, continuous advancements have transformed these devices from auxiliary drives into reliable main drives for a wide range of industrial […]

Industrial Automation Supplier & Parts Solutions for Global Manufacturing What Are Industrial Automation Parts? Industrial automation parts encompass a broad range of electrical and electronic components designed to control, monitor, and automate machines, production lines, and industrial processes across factories, warehouses, and manufacturing plants. In today’s competitive manufacturing environment, businesses increasingly rely on industrial automation parts to […]

Tight Tolerance Machining: How to Achieve High-Precision CNC Parts What is Tight tolerance machining ? In modern manufacturing, machining tolerance refers to the allowable variation in a part’s physical dimensions, usually expressed as plus or minus values from the nominal size. When components are produced with extremely minimal deviation—often within thousandths of an inch or even microns—they are […]