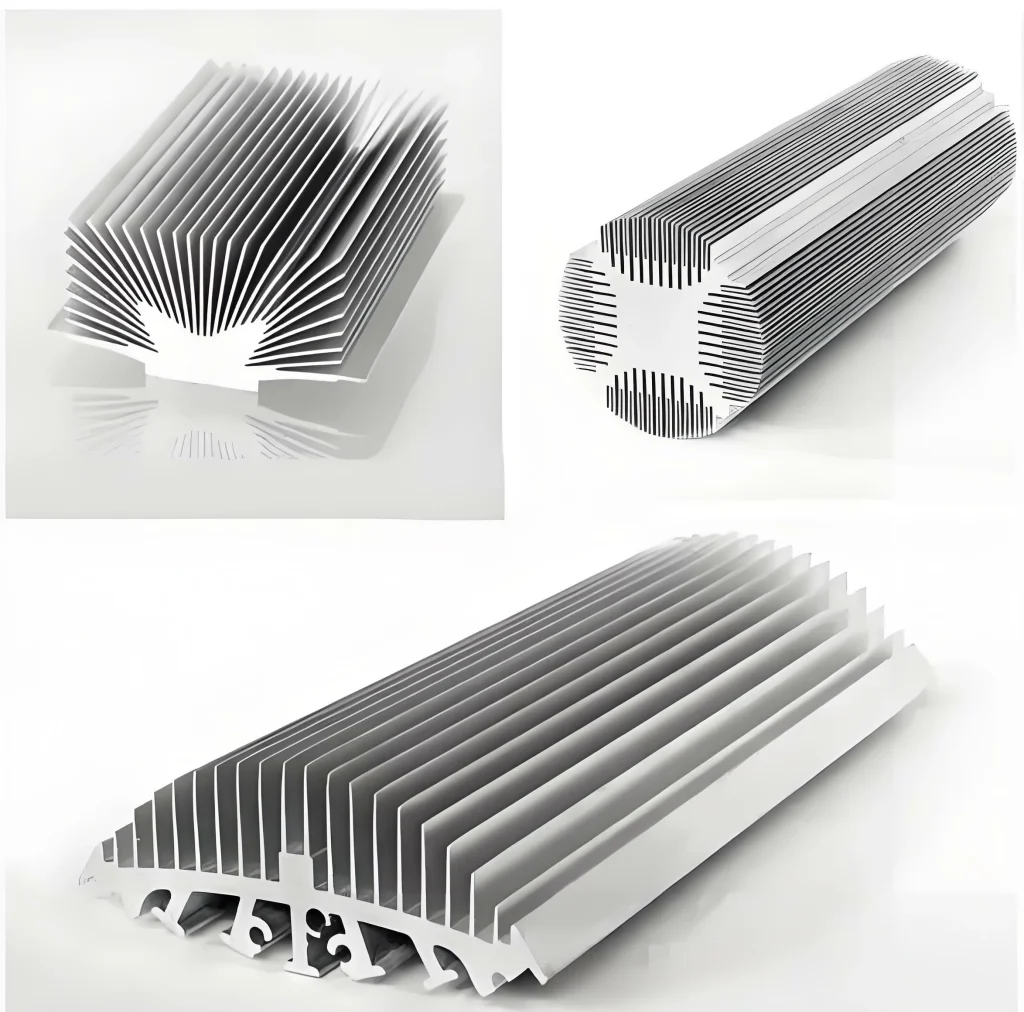

Aluminum Heat Sink Issues: Common Defects and Detection Strategies

1.Why Defect Detection Matters

Manufacturers often face aluminum heat sink issues, including hidden defects that can severely reduce thermal performance, compromise safety, and shorten device lifespan.

A professional aluminum heat sink inspection not only identifies visible flaws like surface irregularities but also uncovers microscopic or structural defects invisible to the naked eye. Whether it’s a heat sink quality inspection, aluminum heat sink testing service, or a comprehensive aluminum heatsink QC service, early detection ensures compliance with industry standards and prevents costly failures down the line.

This guide explains common aluminum heat sink defects, how professionals detect them, and the most effective strategies to avoid them.

2.Understanding Aluminum Heat Sink Defects

Aluminum heat sinks play a critical role in dissipating heat from components like CPUs, LED lighting, automotive electronics, and industrial machinery. Aluminum heat sink issues, such as manufacturing defects or material flaws, can result in:

Poor thermal conductivity

Uneven heat distribution

Mechanical instability

Increased failure rates in high-performance devices

(1)Common defect categories include:

1.Material Defects – Alloy inconsistencies, impurities, or poor extrusion quality.

2.Manufacturing Defects – Warping, bent fins, rough edges from machining.

3.Assembly Defects – Improper mounting, loose screws, or poor thermal interface material application.

3.The Most Common Defects in Aluminum Heat Sinks

| Defect Type | Description | Impact on Performance |

| Surface Roughness | Milling marks or pitting | Reduced surface area for heat dissipation |

| Warped Fins | Bent or uneven fins from handling | Uneven airflow, reduced cooling |

| Porosity | Air pockets in aluminum casting | Lower thermal conductivity |

| Oxidation/Corrosion | Chemical degradation over time | Structural weakening |

| Improper Coating | Uneven anodizing or powder coat | Inconsistent heat transfer |

| Assembly Gaps | Poor contact with components | Higher thermal resistance |

4.How Professionals Detect Hidden Defects

Professional heat sink defect detection services use advanced methods to uncover flaws before they cause failures.

Inspection Tools & Methods:

1.Visual Inspection with Microscopy – Detects surface flaws & micro-cracks.

2.Dimensional Measurement (CMM) – Checks against CAD specifications.

3.Thermal Imaging – Identifies hot spots caused by poor conductivity.

4.X-Ray & Ultrasonic Testing – Finds internal voids or porosity.

5.Surface Profilometry – Measures roughness affecting heat transfer efficiency.

5.Why Aluminum Heat Sinks Fail Thermal Tests

Failing thermal performance tests can stem from:

Excessive porosity in the aluminum

Warping during manufacturing or transportation

Oxidation buildup on contact surfaces

Incorrect installation pressure or uneven torque

A reliable heat sink defect testing service can pinpoint these issues early in the production cycle, allowing corrective actions before mass production.

6.Preventing Manufacturing Defects in Heat Sinks

(1)Preventive strategies include:

1.Material Certification – Verify aluminum grade meets thermal conductivity requirements.

2.Process Control – Monitor extrusion and CNC parameters.

3.Surface Treatment Checks – Ensure anodizing/powder coating is uniform.

4.Regular QC Audits – Partner with a professional heat sink defect detection service for periodic checks.

7.Inspection Frequency Recommendations

(1)How often should aluminum heat sinks be inspected?

Prototype Stage – 100% inspection for performance validation

Mass Production – Random sampling every lot

High-Reliability Applications – Routine inspections every 3–6 months

For OEMs in electronics or automotive, industrial aluminum heat sink inspection solutions are essential for preventing warranty claims and field failures.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

9.Welleshaft: Your Partner in Heat Sink Quality Control

Welleshaft provides aluminum heatsink QC service for electronics, OEM suppliers, and industrial clients.

Notre on-site aluminum heat sink defect detection covers:

Visual & dimensional inspection

Thermal performance testing

NDT techniques for hidden defects

Assembly verification for consistent performance

Whether you’re launching a new product or troubleshooting failures, our team delivers reliable heat sink defect testing services that safeguard your reputation.

10.Client Success Story

A leading LED lighting OEM faced 25% higher return rates due to overheating. Our professional heat sink defect detection service identified porosity in the aluminum extrusion et assembly misalignment.

Results:

Reduced defect rate to <2%

Extended product lifespan by 30%

Improved customer satisfaction scores by 40%

12.FAQ

1: Can defects in aluminum heat sinks affect device performance?

Yes, even small imperfections can raise component temperatures, leading to reduced efficiency and premature failure.

2: What standards apply to aluminum heat sink inspection?

Common standards include ISO 9001, IATF 16949, and IEC thermal performance benchmarks.

3: How do professionals identify hidden flaws in heat sinks?

Techniques like X-ray, ultrasonic testing, and thermal imaging reveal defects invisible during visual inspection.

This article was written by the Welleshaft Technical Quality Team, specialists in thermal component inspection and manufacturing quality assurance. With over 15 years of experience in aluminum heat sink inspection, our experts help OEMs and manufacturers worldwide achieve consistent, reliable performance.