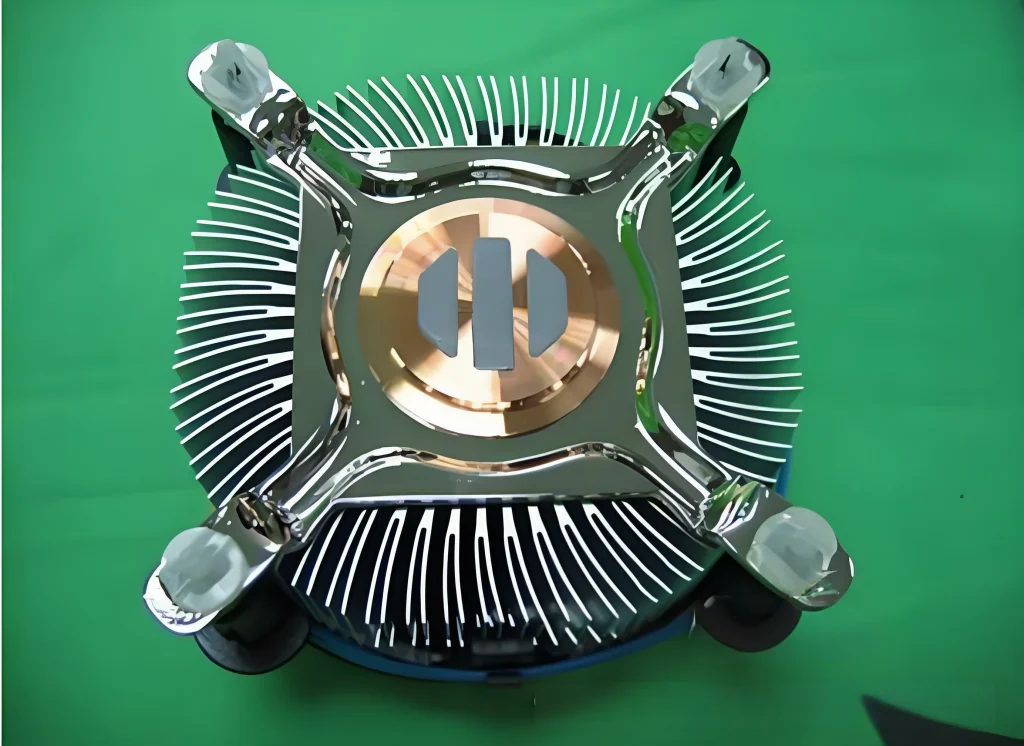

Custom Skived Fin Heatsink Manufacturing Services

When sourcing a custom skived fin heatsink manufacturer in China, Many buyers face challenges such as inconsistent thermal performance, long lead times, and unclear cost structures. Understanding How to Choose a Reliable Skived Fin Heatsink Manufacturer in China is essential when selecting a factory-direct supplier for the USA market or securing skived fin heat sink OEM services for industrial electronics. The process often involves navigating both technical and management hurdles—from ensuring skiving process precision to making the right material selection between copper skived fin heat sinks et aluminum skived fin heat sinks.

This guide explains how to choose a reliable skived fin heatsink manufacturer in China, what technical and supply chain risks to avoid, and how to ensure stable, high-performance thermal solutions for your global electronics projects.

Skived Fin Heatsink Manufacturing Pain Points & How to Choose a Reliable Manufacturer in China

Skived Fin Fabrication Challenges & How to Choose a Reliable Manufacturer in China

- Thermal inefficiency– Poor high-density skived fins design reduces overall thermal conductivity skived heat sink

- Dimensional inconsistency– Variations in skived heatsink production affect precision assembly.

- Material selection issues– Choosing between aluminum vs. copper skived fin heat sinks impacts both cost and efficiency.

Management and Supply Chain Issues

- Lead time unpredictabilitypour skived fin heatsink manufacturing.

- Communication gapsbetween suppliers exporting to USA, Germany, Brazil, and India.

- Cost overrunsdue to inefficient skived fin machining processes.

Industry Impact and Ripple Effects

- Cost impact:Rejected batches increase material and labor costs.

- Delivery delays:Affect project schedules and client commitments.

- Quality concerns:Reduced thermal performance decreases product reliability.

- Brand reputation:OEMs risk client dissatisfaction when working with non-certified precision skived fin heat sink suppliers.

Example:

A European electronics firm importing from non-certified suppliers reported a 15% defect rate in copper skived fin heat sinks, leading to delayed product launches and additional replacement costs.

Skived Fin Heatsink Problems: Root Causes & Choosing a Reliable Manufacturer in China

Technical Reasons

- Lack of precision in skiving process.

- Absence of in-house testingpour thermal conductivity skived heat sink performance.

- Non-standardized skived fin fabrication

Management Reasons

- Missing ISO-certified quality control(ISO 9001, ISO 14001).

- Limited export experienceto USA, India, and Brazil.

- Poor project trackingfor overseas clients.

Short-Term Solutions

- Supplier Audit– Visit the factory or verify production samples.

- Material Verification– Confirm correct copper/aluminum alloy

- Process Confirmation– Ensure precision skiving heat sink standards are met.

- Timeline Agreement– Define delivery lead times and penalties for delays.

Optimizing Long-Term Strategy: Choose a Reliable Skived Fin Heatsink Manufacturer in China

- Automate skived heatsink productionfor consistency.

- Standardize ASTM B499, GB/T 5237, or ISO 9001quality checks.

- Maintain export documentation for major markets.

- Partner with a custom skived fin heatsink OEM manufacturer from Chinafor co-engineered improvements.

Case Study and Comparison Analysis

| Metric | Before Optimization | After Certified Supplier | Improvement |

| Lead time | 6 weeks | 3 weeks | -50% |

| Defect rate | 12% | <2% | -10 pts |

| Thermal efficiency | 85% | 97% | +12% |

Observation: Partnering with a precision skived fin heat sink supplier significantly improved both delivery speed and product reliability for global industrial electronics clients.

Frequently Asked Questions

(1)How to choose a reliable skived fin heatsink manufacturer in China?

Verify ISO 9001, ASTM B499, GB/T 5237 certifications, request product samples, and confirm export experience to USA, Germany, and Brazil.

(2)Which skived fin heatsink suppliers export to the USA and Europe?

Choose suppliers with 10+ years export experience et OEM skived fin machining services for industrial applications.

(3)Can I get custom skived fin heat sinks for electronics cooling projects?

Yes, certified custom aluminum skived fin heat sink suppliers provide optimized solutions for thermal management performance.

Welleshaft’s engineering team has over 10 years of experience in custom skived fin heatsink manufacturing and precision thermal management solutions for global electronics clients. Our engineers specialize in skived fin machining, skived heatsink production, and compliance with ASTM, GBet ISO standards, ensuring reliable performance and on-time delivery for OEM and industrial projects.