Bevel Gear Assembly – Key Considerations for Optimal Performance | Welleshaft

1.Why Precision Bevel Gear Assembly Matters

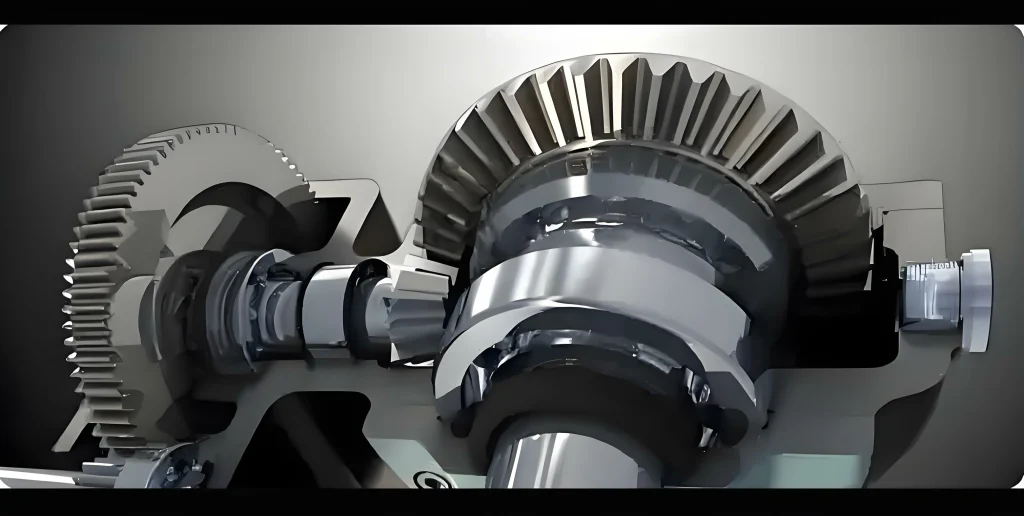

In industrial and automotive applications, achieving Bevel Gear Assembly for Optimal Performance is a critical process that directly impacts machinery efficiency, durability, and operational reliability. Many businesses struggle with the complexity of assembling bevel gears, resulting in low efficiency, misalignment, excessive wear, and noise. Leveraging proper bevel gears manufacturing, bevel gear inspection serviceset precision bevel gear production practices can dramatically improve outcomes. At Welleshaft, our expertise ensures every bevel gear assembly meets the highest standards of accuracy, durability, and performance.

2.Understanding Bevel Gear Types and Their Applications

Bevel gears come in several configurations, including straight bevel gears, spiral bevel gears, and zerol bevel gears. Each type serves specific industrial needs:

- Straight bevel gears– Simple, cost-effective, ideal for light-load applications.

- Spiral bevel gears– High-performance, capable of handling high-torque applications, commonly used in automotive and marine gearboxes.

- Zerol bevel gears– Hybrid design with smooth operation and reduced vibration.

Correct selection of bevel gear types is essential for achieving optimal alignment, efficiency, and lifespan.

3.Common Challenges in Bevel Gear Assembly

Many clients encounter issues such as:

- Misalignment during assemblyleading to premature wear

- Noise and vibrationdue to incorrect tooth meshing

- Lubrication problemsshortening operational lifespan

- High defect ratesin custom or complex assemblies

By leveraging CNC bevel gear production, industrial bevel gear inspectionet precision bevel gear assembly for automotive applications, these challenges can be mitigated.

4.Key Steps for Optimal Bevel Gear Assembly

(1)Pre-Assembly Inspection

Before assembly, ensure bevel gear quality inspection is completed:

- Check tooth geometry and tolerances

- Verify spiral miter gears and pinion alignment

- Identify any surface defects from custom bevel gear manufacturing

(2)Proper Alignment and Installation

- Use bevel gear alignment and installation services tools to ensure precise meshing.

- Maintain OEM bevel gear assembly and calibration servicestolerances for automotive and industrial machinery.

- Misalignment can cause vibration and efficiency loss.

(3)Lubrication Setup

- Implement a bevel gear lubrication system setup for extended lifespan.

- Proper lubrication reduces friction, heat, and wear.

- Use ISO-certified oils compatible with high-performance bevel gear assembly for marine gearboxes.

(4)Testing and Verification

- Conduct bevel gear assembly inspection and quality control.

- Test for smooth rotation, torque transmission, and noise.

- How do you test a bevel gear assembly for efficiency?Measure power loss and vibration levels during operation.

5.Best Practices in Bevel Gear Assembly

- Follow precision bevel gear assembly for automotive applications

- Avoid common mistakes such as over-tightening or incorrect spacing.

- Schedule regular inspections: How often should bevel gear assemblies be inspected?Typically every 6–12 months depending on workload.

- Use bevel gear failure analysis and corrective assembly solutionsif performance issues arise.

Table: Best Practices for Bevel Gear Assembly

| Practice | Benefit | Recommended Tools/Methods |

| Alignment verification | Reduced wear & vibration | Dial indicators, laser alignment |

| Tooth contact pattern check | Optimal load distribution | Gear marking compound |

| Lubrication system setup | Extended gear life | ISO-certified oils |

| Post-assembly testing | Performance assurance | Torque tester, vibration analyzer |

6.Specialized Assembly Services by Welleshaft

Welleshaft offers end-to-end solutions for bevel gear assembly services for industrial machineryy compris :

- Custom bevel gear assembly solutions for heavy equipment

- Spiral bevel gear assembly for high-torque applications

- Bevel gear retrofit and upgrade solutions

- ISO-certified processes ensuring high-performance bevel gear assembly

Clients benefit from expert bevel gear assembly services, reducing downtime and operational costs.

7.Troubleshooting and Maintenance

Proper maintenance ensures longevity:

- Bevel gear noise and vibration troubleshooting services to identify misalignment or gear wear

- Bevel gear assembly maintenance contracts for factories for routine inspections

- Lubrication monitoringpour spiral gear and bevel gear and pinion assemblies

8.Case Study – Automotive Gearbox Upgrade

A major automotive OEM faced repeated failures in spiral bevel gear assemblies for high-load applications.

- Issue: Misalignment and inadequate lubrication

- Solution: Welleshaft provided precision bevel gear assembly with alignment, calibration, and lubrication optimization

- Result: Noise reduced by 40%, efficiency improved by 25%, and component lifespan extended by 30%

9.FAQ – Bevel Gear Assembly

(1)How do you align bevel gears during assembly?

Use precision dial indicators, laser tools, and contact pattern verification to ensure accurate alignment.

(2)What tools are needed for precise bevel gear assembly?

- Torque wrenches

- Dial indicators

- Gear marking compound

- Laser alignment systems

(3)How to reduce noise in bevel gear assembly?

- Ensure proper tooth meshing

- Maintain correct backlash

- Use recommended lubrication

(4)Can bevel gear assemblies be reconditioned instead of replaced?

Yes, bevel gear retrofit and upgrade solutions allow refurbishment of worn gears to restore performance.

Written by the Welleshaft Engineering Team – specialists in bevel gears manufacturing et precision bevel gear assembly with over a decade of experience in industrial, automotive, and heavy equipment applications. Our engineers help clients optimize gear performance, reduce failures, and extend machinery lifespan.