Carburizing: Steel Surface Hardening for Increased Wear Resistance Section 1 Introduction In the realm of materials science and engineering, the quest for materials that offer both strength and durability is perpetual. Steel, a cornerstone of modern industry, is constantly being enhanced to meet the rigorous demands of diverse applications. One such crucial enhancement is surface hardening, […]

Monthly Archives: enero 2025

Salt Bath Nitriding Services: Improve Metal Hardness & Wear Resistance Section 1 Introduction In today’s demanding manufacturing landscape, the performance and longevity of metal components are paramount. Achieving superior surface properties, like enhanced hardness and wear resistance, is crucial for extending the lifespan of critical parts and ensuring optimal functionality. One effective solution for achieving these […]

MIM Gear Process: Achieve Complex Gear Designs with Metal Injection Molding Section 1 Introduction Metal Injection Molding (MIM) has emerged as a transformative manufacturing process, particularly for creating intricate and high-performance components like gears. The MIM Gear Process combines the design flexibility of injection molding with the material properties of powder metallurgy, allowing for the production […]

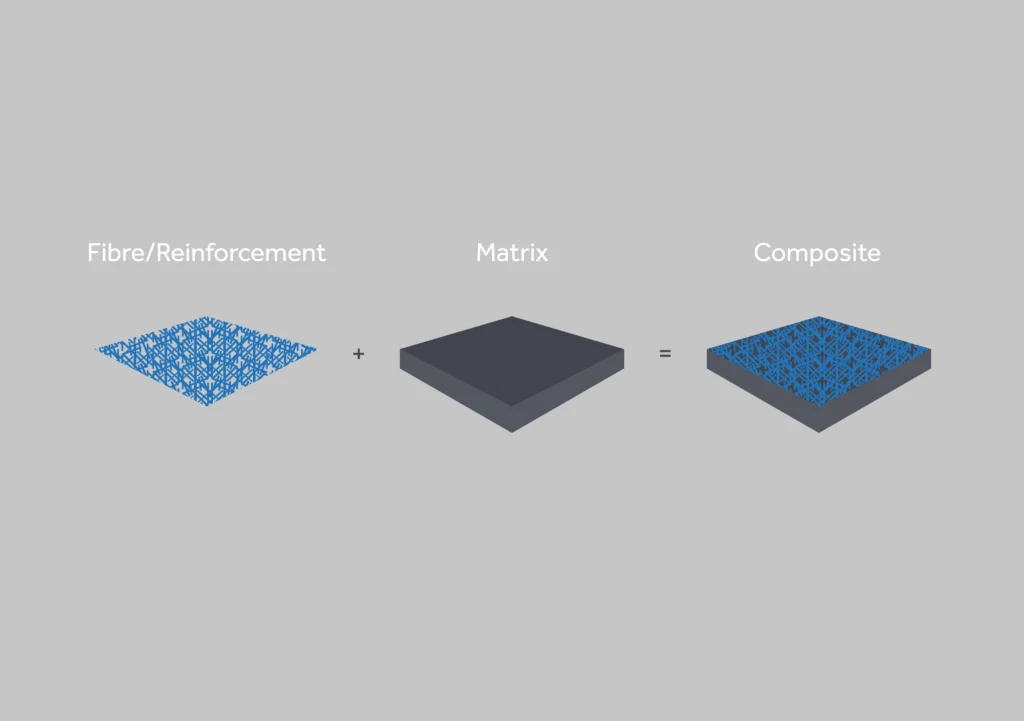

Resin Matrix Composite Material Processing: Layup, Curing & Advanced Manufacturing Section 1 Introduction Resin matrix composites have revolutionized industries ranging from aerospace and automotive to sporting goods and medical devices. Their exceptional strength-to-weight ratio, design flexibility, and corrosion resistance have made them indispensable in modern manufacturing. This article delves into the intricate world of Resin Matrix […]

Reliable Ceramic Component Grinding and Processing Services | Solving Your Machining Challenges Section 1 Introduction In today’s advanced engineering landscape, ceramic materials are increasingly vital for their exceptional properties: high hardness, thermal resistance, chemical inertness, and electrical insulation. However, these very attributes make them notoriously difficult to machine. Ceramic component grinding and precision processing demand specialized […]

Encapsulated Ceramic Electronic Components – High-Quality Ceramic & Protection Section 1 Introduction In today’s technologically advanced world, the demand for reliable and robust electronic components is continually growing. Encapsulated ceramic electronic components have emerged as a leading solution for applications requiring high performance, durability, and protection against harsh environments. These components leverage the exceptional properties of […]

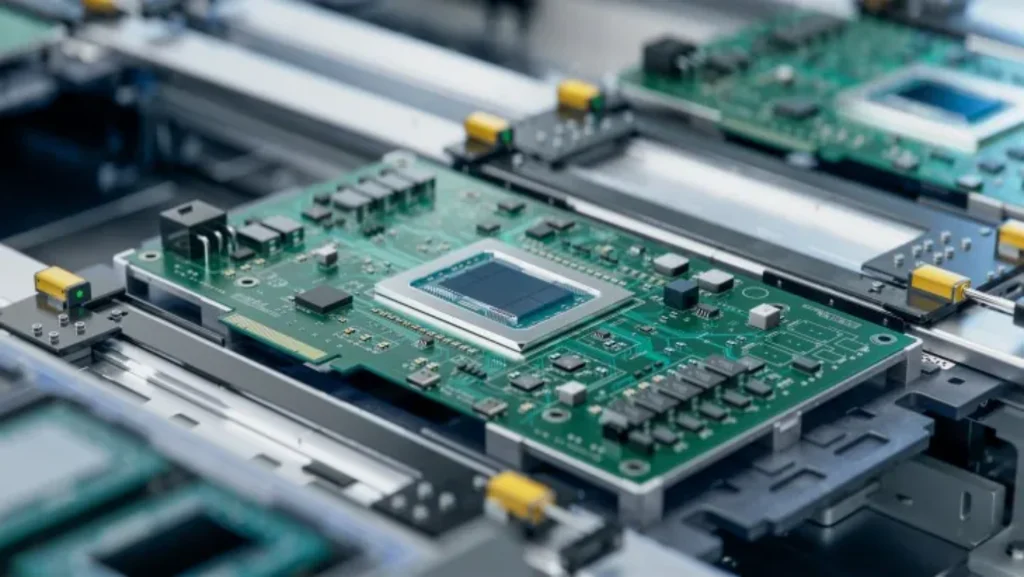

Enhance Semiconductor Production with High-Performance Ceramic Equipment Parts The semiconductor industry is at the heart of modern technology, powering everything from smartphones to advanced medical devices. As demand for microchips continues to soar, manufacturers are constantly seeking ways to improve production efficiency, precision, and yield. A critical, often overlooked, component in this quest lies in […]

Reduce Spatter with Quality Argon Arc Welding Ceramic Nozzles Section 1 Introduction Argon arc welding, also known as Tungsten Inert Gas (TIG) welding or Gas Tungsten Arc Welding (GTAW), is renowned for its precision and high-quality welds. However, welders often face the challenge of spatter—unwanted molten metal droplets that cause imperfections, waste materials, and extra cleaning. […]

Reduce Spatter with Quality Argon Arc Welding Ceramic Nozzles Section 1 Introduction Argon arc welding, also known as Tungsten Inert Gas (TIG) welding or Gas Tungsten Arc Welding (GTAW), is renowned for its precision and high-quality welds. However, welders often face the challenge of spatter—unwanted droplets of molten metal that cause imperfections, wasted materials, and extra […]

Ceramic Rollers for Printing & Conveying: Durable and Accurate for Optimal Results Section 1 Introduction In the world of industrial manufacturing and printing, precision and reliability are paramount. The efficiency and quality of processes like conveying and printing often hinge on the performance of seemingly simple components: rollers. Manufacturers increasingly choose ceramic rollers for applications demanding […]