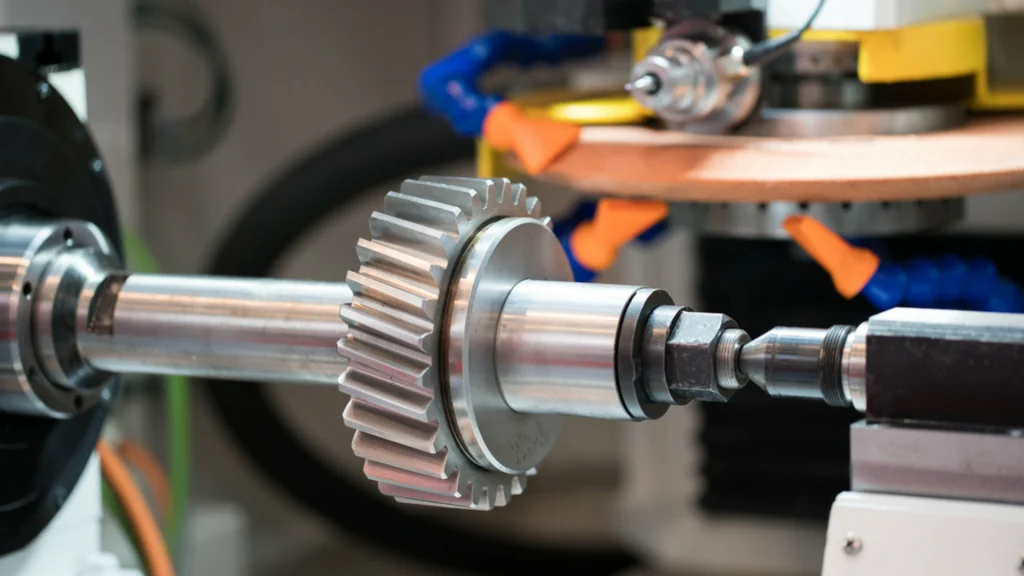

Gear Grinding Services: Hardened Steel Gear Finishing In the realm of precision engineering, gears stand as critical components across various industries, from automotive and aerospace to manufacturing and robotics. To achieve optimal performance, longevity, and minimal noise, gears often require a high degree of accuracy and a superior surface finish, especially after heat treatment. This […]

Category Archives: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

Precision Gear Broaching Services | Internal & External Gear Cutting In the world of precision manufacturing, gears play a critical role. From automotive transmissions to aerospace components, the accuracy and quality of gears directly impact the performance and reliability of countless machines and systems. When it comes to producing gears with exceptional precision, intricate profiles, […]

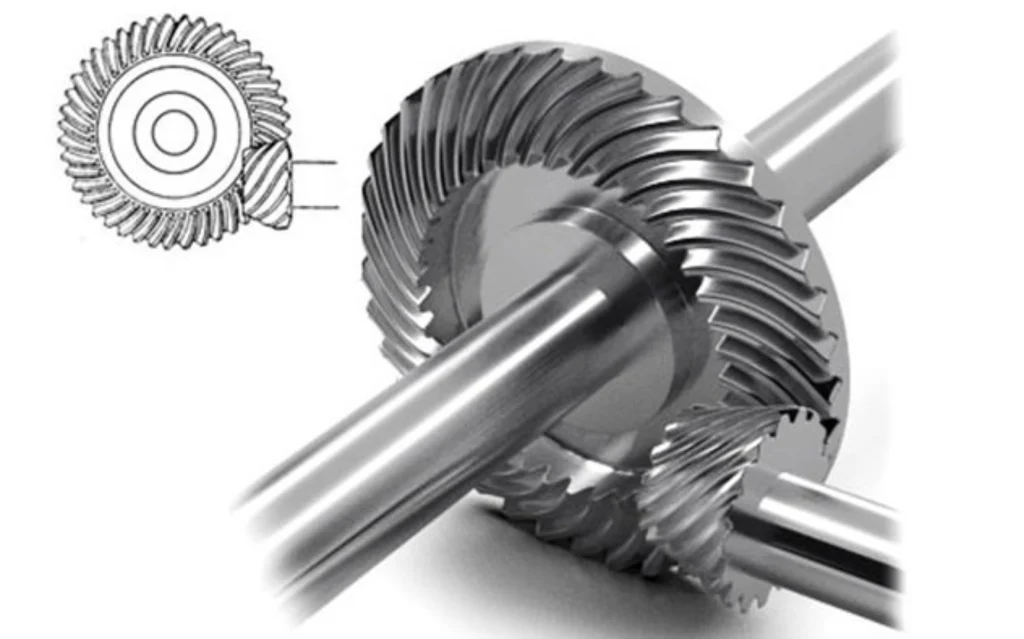

Solving Gear Drive Challenges with Hypoid Gears Gear drives are the unsung heroes of mechanical systems, silently translating power and motion across countless applications. However, designers often face significant challenges when selecting the optimal gear type. Space constraints, noise reduction, high torque requirements, and the need for non-intersecting shafts can all present difficult hurdles. Enter […]

Bevel Gears for Power Transmission & Angle Drives Bevel gears are essential components in mechanical systems, playing a vital role in transmitting power between intersecting shafts. Their unique conical shape allows for changes in rotational direction, making them indispensable in various applications, from automotive differentials to industrial machinery. This article explores the diverse world of […]

Sintered Alumina for Seals & Bearings: Precision, Durable Ceramics Introduction In the world of high-performance engineering, the selection of materials for critical components like seals and bearings is paramount. Sintered alumina, a precision ceramic material, stands out as a superior choice due to its exceptional combination of hardness, wear resistance, chemical inertness, high-temperature stability, and […]

Porous Alumina Membranes: High-Performance Filters & Separators Introduction In the realm of advanced materials and engineering, porous alumina membranes have emerged as a leading solution for high-performance filtration and separation processes. Their unique combination of chemical inertness, thermal stability, controlled pore size, and mechanical strength makes them ideal for a wide array of applications across […]

Alumina Filters | Advanced Ceramic Filters for Chemical Processing Alumina filters, also known as aluminum oxide filters, represent a sophisticated solution for demanding filtration applications across various industries, particularly in chemical processing. These filters leverage the exceptional properties of alumina ceramics to deliver superior performance compared to conventional filtration methods. This article delves into the […]

Alumina Insulators: High-Performance Ceramic Electrical Insulation Alumina (Aluminum Oxide, Al₂O₃) insulators are a cornerstone of modern electrical and electronic engineering, offering exceptional performance in demanding applications. Their unique combination of high dielectric strength, thermal stability, chemical inertness, and mechanical robustness makes them a preferred choice over other insulating materials in many industries. This article will […]

Alumina Disc Substrates for Thin Film Deposition Introduction In the realm of microelectronics, optics, and materials science, thin film deposition plays a crucial role in creating advanced devices and structures. The quality and performance of these thin films are highly dependent on the substrate upon which they are deposited. Alumina disc substrates, renowned for their […]

Medical Grade Aluminum Oxide: Bio-Compatibility & Implant Applications Introduction Medical-grade aluminum oxide, also known as alumina (Al₂O₃), is a high-purity ceramic material prized for its exceptional bio-compatibility, wear resistance, and chemical inertness. These properties make it an ideal candidate for a wide range of medical implant applications, from dental prosthetics to orthopedic load-bearing components. This […]