1. A 356 Aluminum Castings: All-in-One Solutions for Industrial Needs

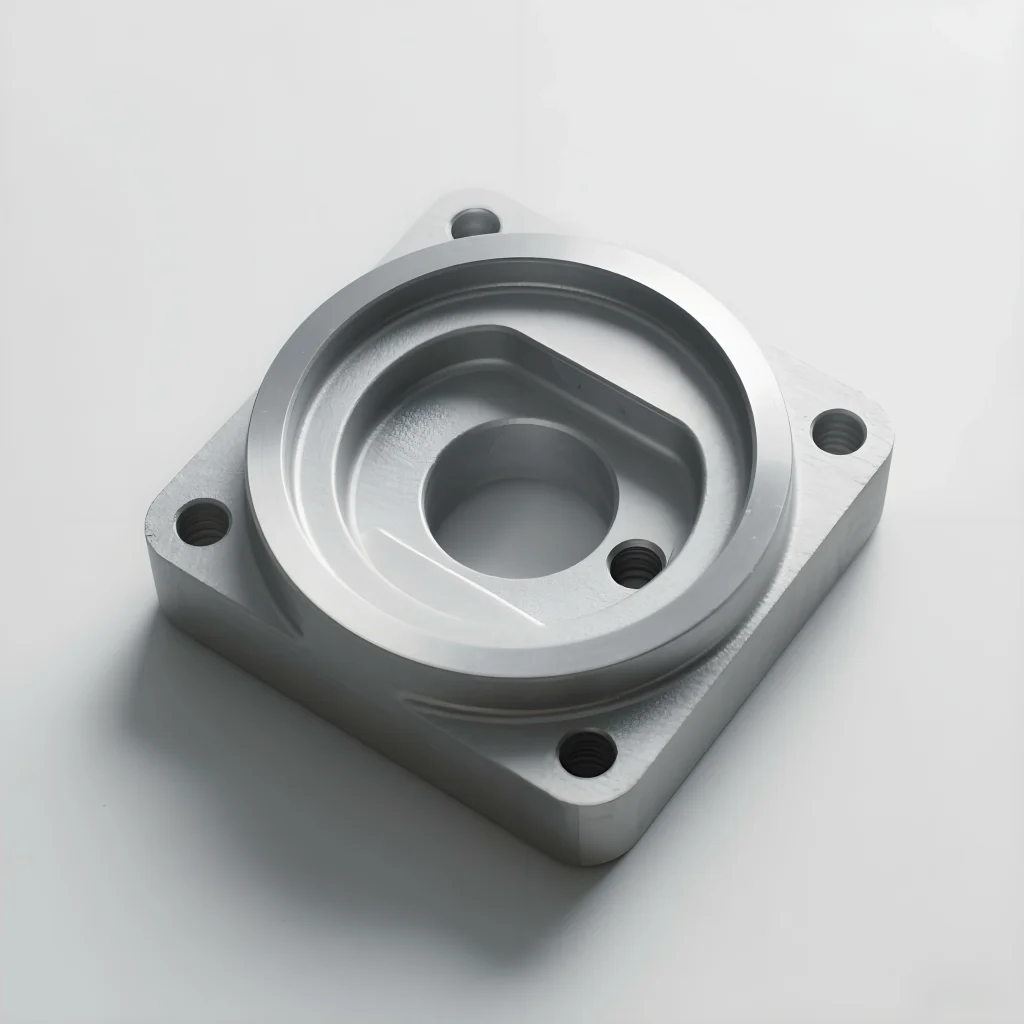

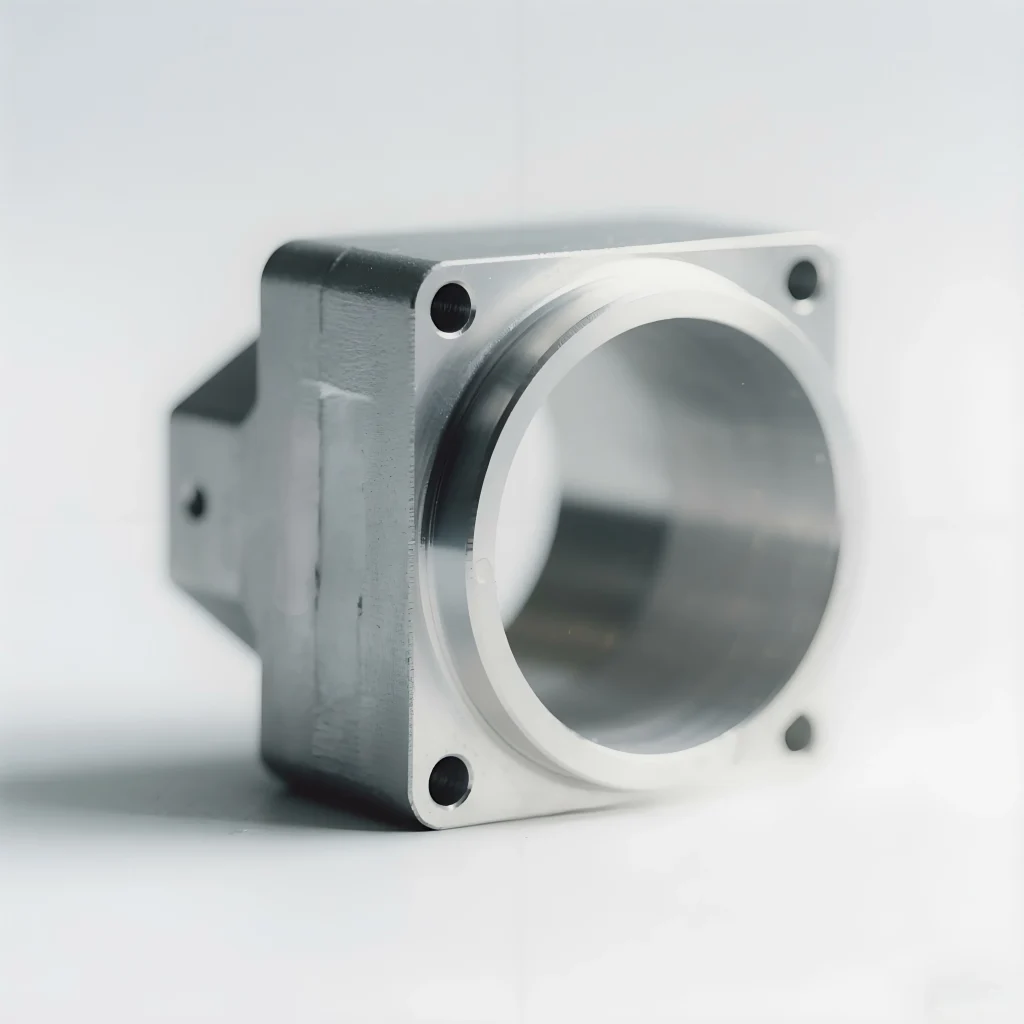

Welleshaft crafts high-quality investment castings using ASTM A356 Aluminum, known for its excellent versatility, superior corrosion resistance, and robust durability—ideal for complex, long-lasting components. As a trusted supplier, we specialize in ASTM A356 Aluminum casting solutions with in-house custom tooling, supporting both high-volume production and precision cast parts tailored to niche industry applications.

2. A 356 Aluminum: Why It Stands Out

A 356, often called a 356 aluminum, earns its spot in manufacturing for balanced mechanical properties. From a 356 aluminum casting to high-precision investment castings, this alloy shines for:

- Strength-to-Weight Ratio: Critical for fields like automotive, where cutting weight without losing strength matters. This answers “why use a 356 aluminum alloy in automotive”—a question manufacturers often ask when aiming to boost fuel efficiency and performance.

- Corrosion Resistance: A big plus, especially for a 356 aluminum corrosion resistance fr construction, marine settings, and outdoor structures.

- Castability: Its smooth flow when molten makes it perfect for complex shapes, outdoing many alternatives in “a356 vs other aluminum alloys for automotive castings” or “a356 vs 6061 for structural castings.”

For cars, high strength a356 cast aluminum for car parts and a356 investment casting for electric vehicle housings use these traits. In aerospace, a356 aluminum properties for aerospace applications—like heat stability and tensile strength—make it a must-have.

3. A 356 Investment Casting: Pros and Processes

Welleshaft’s a356 investment casting process offers unique benefits, tailored to meet strict industry standards:

- Complex Shapes: Perfect for high-precision a356 aluminum alloy casting for aerospace, where tight a356 investment casting tolerance for aerospace is a must. This precision also helps low-porosity a356 castings for drones and medical tools, where reliability counts.

- Cost Savings: High-volume runs cut per-unit costs, making it great for price-sensitive projects like a356 cast aluminum for building components price talks or mass-produced car parts.

- Material Consistency: Our process limits investment casting defects in a356 aluminum, ensuring uniformity across batches—whether for aluminio a356 or ASTM A356 certified aerospace investment casting.

- Custom Options: From alloy tweaks to surface finishes (check our anodizing a356 aluminum alloy guide), we adapt to your specific needs.

4. A 356 Aluminum Uses Across Industries

A356 aluminum casting and a356 investment casting serve many sectors, each using the alloy’s unique traits:

-

Automotive: Driving Performance and Efficiency

The auto industry relies heavy on a356 aluminum alloy, and for good reason. Why use A356 aluminum alloy in automotive? Its high strength-to-weight ratio reduces vehicle weight for better fuel efficiency, while its flexibility absorbs road vibrations—ideal for engine blocks and suspension parts.

When comparing A356 vs other aluminum alloys for automotive castings, A356 offers better weldability, easier machining, and suits EV housings where lightweight design boosts battery range.

-

Aerospace: Precision for Critical Parts

Aerospace needs uncompromising accuracy, and our high-precision a356 aluminum alloy casting for aerospace delivers. A356 aluminum properties for aerospace applications—like high tensile strength and resistance to extreme temps—meet strict aviation standards.

As trusted A356 cast aluminum aerospace part manufacturers, we meet ASTM A356 standards with tight casting tolerances to ensure safety in jet engines, brackets, and avionics housings.

-

Construction: Durability for Infrastructure

A356 investment casting uses in construction range from structural brackets to decorative hardware. Its resistance to weather and chemicals addresses a356 aluminum corrosion resistance for construction, making it great for outdoor structures.

-

Medical Devices: Safety and Precision

Precision a356 aluminum alloy casting for medical tools needs to meet strict health standards.We also share tips on a356 aluminum casting sterilization methods, to keep up with healthcare rules.

-

Marine and Specialty Uses

A356 aluminum alloy resists saltwater, making it ideal for marine fittings via sand casting. Its strength and light weight also make it a top choice for bicycle frames.Plus, corrosion-resistant a356 cast aluminum pump housings hold up in industrial fluid systems, thanks to the alloy’s chemical resistance.

5. A356 Aluminum Alloy: Makeup and Traits

The consistent makeup of a356 aluminum alloy (per ASTM A356 standards) is key to its reliability. Here’s its core composition:

| Element | Percentage | Role in Performance |

| Aluminum | 92% | Gives base strength and light weight. |

| Silicon | 7% | Makes casting easier, critical for complex a356 investment casting designs. |

| Magnesium | 0.5% | Boosts strength after heat treatment (see heat treatment process for a356 aluminum). |

| Iron | 0.5% | Makes machining easier, supporting our machining tips for a356 cast aluminum. |

Key physical traits include a356 aluminum density (2.7 g/cm³) and melting point (570–615°C), making it good for high-temp uses like engine parts.

6. A 356 vs Other Aluminum Alloys: A Quick Guide

Knowing how a 356 stacks up against others helps pick the right material:

- A 356 vs A 357 Aluminum Alloy: In “a 356 vs a 357 aluminum alloy comparison,” a 357 is stronger after heat treatment but harder to cast, making a 356 better for complex shapes like high-precision a 356 aluminum alloy casting for aerospace.

- A 356 vs 6061 for Structural Castings: “A 356 vs 6061 for structural castings” favors a 356 for intricate designs because it casts better, while 6061 works better for simple structures that need welding.

7. Why Pick Welleshaft for A356 Castings?

Welleshaft is your go-to for a 356 investment casting, a 356 cast aluminum, and a 356 aluminum alloy solutions, with skills that include:

- Full-Service Expertise: From tool design to CNC machining, we’re a one-stop shop for all a 356 needs, including aluminio a 356 for global markets.

- Quality Checks: Every part meets ASTM A 356 standards, with strict testing to avoid investment casting defects in a356 aluminum.

- Tech Support: Our team helps with heat treatment process for a356 aluminum, anodizing a356 aluminum alloy, and maintenance best practices.

- Custom Work: We adapt to unique needs, from low-porosity a356 castings for drones to corrosion-resistant a356 cast aluminum pump housings.

8. People Also Ask

- What’s the heat treatment process for a356 aluminum?

Heating and aging boost strength—essential for high-strength A356 cast aluminum in cars and aerospace parts. - What are a356 aluminum density and melting point?

A356 has a density of 2.7 g/cm³ and melts between 570–615°C, making it good for high-temp uses like engine parts. - How does anodizing a356 aluminum alloy work?

Anodizing creates a protective layer, boosting corrosion resistance—great for a356 cast aluminum for building components and marine fittings. - Why use a356 in bicycle frames?

Its strength-to-weight ratio means durability without extra bulk, making rides smoother and frames longer-lasting.

9. Get Started with Welleshaft

Need A356 investment casting or aluminum alloy parts? Contact Welleshaft for a quote or browse our project gallery. From automotive to medical, we deliver precise, reliable A356 solutions.