The Ultimate Guide to Anodized Aluminum: Process, Benefits & Industrial Use | Welleshaft

1.Introduction: What Is Anodizing?

How to anodize aluminum: Anodizing is an electrochemical process that enhances aluminum’s natural oxide layer. It improves corrosion resistance, surface hardness, and allows coloring for functional and decorative uses. Anodized aluminum is common in aerospace, construction, electronics, and automotive industries.

2.How to Anodize Aluminum: Step-by-Step Guide

(1)How Do You Anodize Aluminum at Home or in a Plant?

To anodize aluminum, clean the surface, submerge it in an acidic electrolyte bath (usually sulfuric acid), and apply electric current to oxidize the outer layer. This controlled oxidation creates the protective anodized layer. Whether using DIY aluminum anodizing kits or commercial anodizing equipment, the key is voltage control, bath composition, and sealing.

| Step | Description |

| 1 | Clean & degrease the part |

| 2 | Etch and desmut the surface |

| 3 | Submerge in acid electrolyte |

| 4 | Apply direct current |

| 5 | Rinse and dye (optional) |

| 6 | Seal in boiling water or nickel |

3.How Does Anodizing Work? Process and Principle

(1)The Electrochemical Principle of Aluminum Anodization

The anodizing process relies on electrolysis: the aluminum acts as the anode in an acid electrolyte (typically sulfuric acid). When electricity is applied, oxygen ions from the electrolyte bond with the aluminum surface, forming a thick, controlled aluminum oxide layer that is harder than raw aluminum and non-conductive.

This oxide layer is integral to the metal, not applied like paint, so it won’t chip or peel.

4.Types of Anodizing: Type II vs Type III Explained

(1)What Are the Different Types of Anodizing?

1.Type I (Chromic Acid): Thin, corrosion-resistant, limited dye options

2.Type II (Sulfuric Acid): Most common, supports coloring

3.Type III (Hard Anodizing): Thick, wear-resistant for industrial parts

| Type | Thickness | Anmeldung |

| I | ~0.5 µm | Aerospace, tight-tolerance parts |

| II | 3–25 µm | Architectural, decorative |

| III | 25–100 µm | Military, machinery, cookware |

5.Welleshaft’s Technical Capabilities and Certifications

(1)Our Anodizing Equipment, Standards, and QA Systems

At Welleshaft, we operate fully automated aluminum anodizing and painting plants, compliant with MIL-A-8625 and ISO 9001 standards. Our capabilities include:

Type II & Type III anodizing

Color anodizing in black, red, gold, clear, and more

Automated handling systems for consistent quality

Real-time thickness and defect detection (±2 μm accuracy)

RoHS and REACH compliant materials

Located in China’s industrial corridor, we serve clients globally with fast lead times.

6.Why Anodize Aluminum – Purpose and Advantages

(1)What Does Anodizing Do to Aluminum?

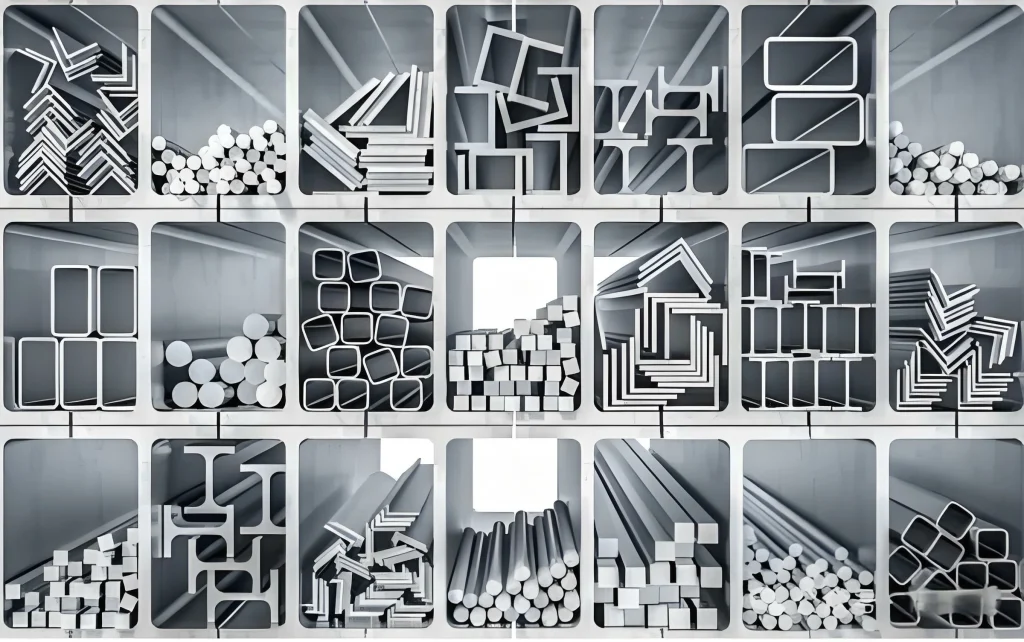

Anodizing enhances corrosion resistance, wear protection, thermal stability, and surface adhesion for paints and sealants. It also allows color customization via dyes and maintains aluminum’s lightweight advantage. Common anodized products include extrusions, trims, cookware, and consumer electronics casings.

7.Real-World Customer Case Study

(1)Case Study – Anodizing for Automotive Components

Client: German Tier 1 automotive supplier

Challenge: High wear resistance and uniform color on brake system housings

Solution: Hard anodizing with strict ±5 μm tolerance, dyed black for UV protection

Result: Over 500,000 units delivered annually with <0.1% rejection rate

8.Anodizing vs Powder Coat vs Cerakote

(1)Which Is Better: Anodized, Powder Coated, or Cerakote?

| Finish | Thickness | Durability | Color Options | Conductivity |

| Anodized | Thin | High | Medium | Yes |

| Powder Coat | Thick | Very High | Very High | No |

| Cerakote | Thin | Very High | High | No |

Anodizing is ideal for precision parts and corrosion resistance; powder coating suits large, aesthetic parts; Cerakote excels in firearms and heat resistance.

9.Common Defects in Anodizing and How to Fix Them

(1)What Are Typical Anodizing Problems?

Pitting: Contamination in bath or poor cleaning

Burn Marks: Excessive voltage or poor agitation

Color inconsistency: Uneven oxide layer or dye

Peeling/Flaking: Improper sealing or surface prep

10.How to Remove Anodizing from Aluminum

(1)Can You Strip Anodized Aluminum?

Yes, anodizing can be removed with sodium hydroxide (lye) solution. Caution is required as it affects the aluminum substrate. Polishing may be necessary afterward to restore appearance.

11.Applications of Anodized Aluminum Across Industries

(1)Where Is Anodized Aluminum Used?

🚗 Automotive: Engine covers, trims, fuel rails

🏢 Architecture: Window frames, curtain walls, cladding

📱 Consumer Electronics: Phone casings, heat sinks

🍳 Cookware: Hard anodized non-stick pans

⚙️ Industrial Equipment: Aerospace, marine, robotics

12.Why Choose Welleshaft for Anodizing Services?

(1)Our Edge in Precision Surface Treatment

8+ years anodizing experience across industrial sectors

Dedicated R&D for color matching and corrosion testing

MIL-spec & ISO certified QA team

Batch traceability and REACH/RoHS documentation

English-speaking technical support and design consulting

13.Call to Action: Upgrade Your Aluminum Finishes Today

Partner with Welleshaft for:

Custom anodizing for trims, tubes, and extrusions

Type II and Type III MIL-compliant finishes

Color matching and protective coatings

Fast-turnaround on industrial batches

14.People Also Ask

(1)Does anodized aluminum rust?

No, anodizing significantly improves aluminum’s corrosion resistance. However, poor sealing may cause discoloration in harsh environments.

(2)Is anodized aluminum conductive?

The oxide layer is non-conductive, but the base aluminum remains conductive underneath.

(3)Can you dye anodized aluminum different colors?

Yes, Type II anodizing allows organic and inorganic dyeing. Popular colors include black, red, blue, and gold.

(4)Does anodizing add thickness?

Yes. Anodizing increases part dimensions slightly—typically 50% of the oxide layer penetrates the surface, and 50% adds external thickness.

From DIY kits to industrial-scale anodizing solutions, anodized aluminum offers durability, corrosion protection, and aesthetic flexibility. Whether you’re exploring how to anodize aluminum at home or comparing anodizing vs powder coat, Welleshaft is your trusted partner for expert surface finishing.

📚 Bookmark this guide to stay informed on anodizing best practices and standards.

Need Expert Advice? Contact our technical support team at Welleshaft to get custom anodizing solutions tailored to your project.