High-Quality Precision Forging Services | Expert Metal Forging Solutions In the realm of metal manufacturing, precision forging stands out as a pivotal process, delivering high-quality, durable components that meet stringent specifications. This article explores the intricacies of precision forging, including its definition, processes, and benefits, while highlighting Welleshaft as a leading global supplier and contract […]

Category Archives: Study cases and knowledge

Discover industriy trends, case studies, how-to guides, manufacturing processes and FAQs on Welleshaft’s Knowledge Hub—expert insights for engineers and sourcing professionals.

Welleshaft’s Study Cases and Knowledge page addresses key sourcing challenges, quality control hurdles, and real manufacturing pain points—helping buyers make smarter, faster decisions.

Medical Grade & Surgical Stainless Steel | Custom SS455 PER ASTM F899 Solutions Precision, durability, and reliability drive success in the medical and surgical fields. Manufacturers rely on medical-grade stainless steels—especially SS455—to meet the strict standards of surgical instruments and implants. By adhering to ASTM F899 standards, engineers design custom stainless steel solutions like SS455 […]

Expert Titanium Forging Services | Precision & Quality in Metal Forging Titanium forging is a specialized process that transforms raw titanium into high-performance components used across various industries. Renowned for its strength, light weight, and resistance to corrosion, titanium is an ideal material for aerospace, medical, and industrial applications. In this article, we’ll explore the […]

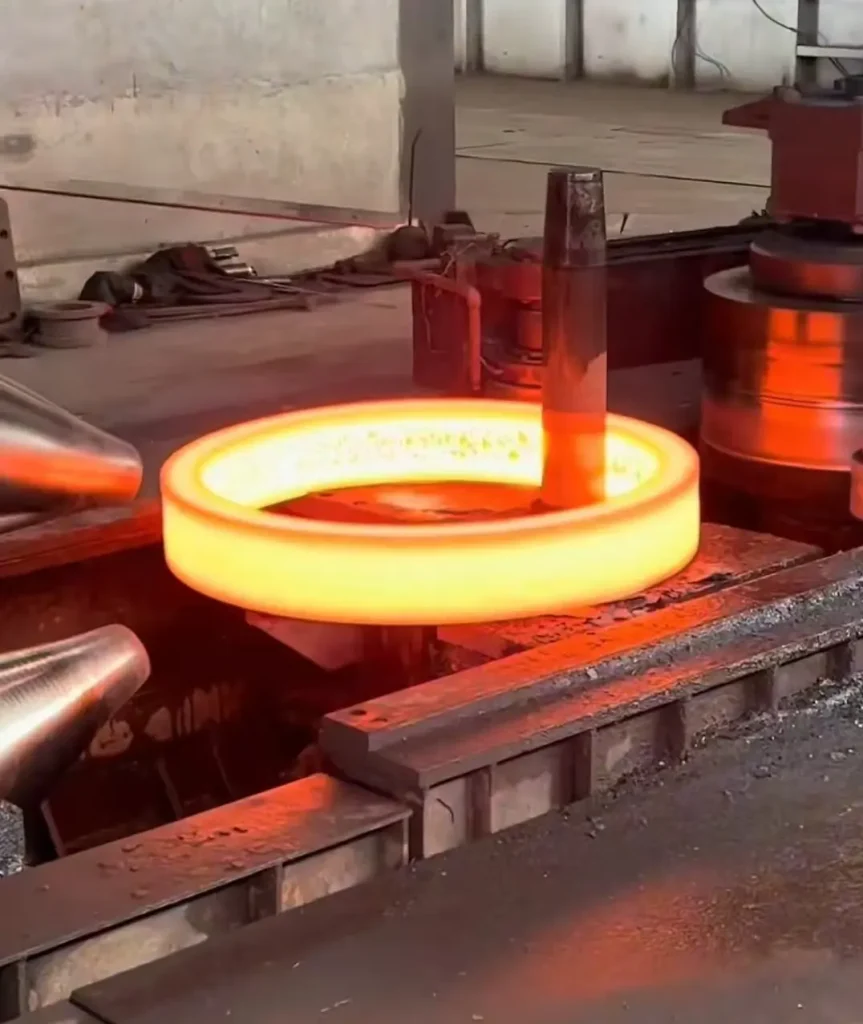

Rill Rolling for Sale: A Comprehensive Guide to Ring Rolling and Rolled Ring Forging Rill rolling might not be a widely recognized term, but it often refers to the detailed and technical aspects of ring rolling and rolled ring forging. These processes are pivotal in creating high-quality metal rings used across various industries. This article […]

Brass Forging: A Comprehensive Guide Brass forging is a crucial process in manufacturing high-quality brass components used across various industries. Whether you’re a manufacturer, engineer, or hobbyist, Brass Forging: A Comprehensive Guide will help you understand the benefits of forged brass parts. In this article, we explore everything you need to know about brass forging, […]

Dear Valued Customers, As the Mid-Autumn Festival approaches, we want to extend our heartfelt wishes for peace, prosperity, and happiness to you and your family during this festive season. May the full moon bring harmony and joy to your home. At Welleshaft, we deeply appreciate your continued trust and support. We remain committed to providing […]

Customer Satisfaction Feedback: The Key to Success in Contract Manufacturing In the fast-evolving world of manufacturing, customer satisfaction is the driving force behind business growth. For industries relying on contract manufacturing, ensuring customer needs are met is crucial to success. From CNC machining manufacturers to medical device contract manufacturing and cosmetics contract manufacturing, maintaining high […]

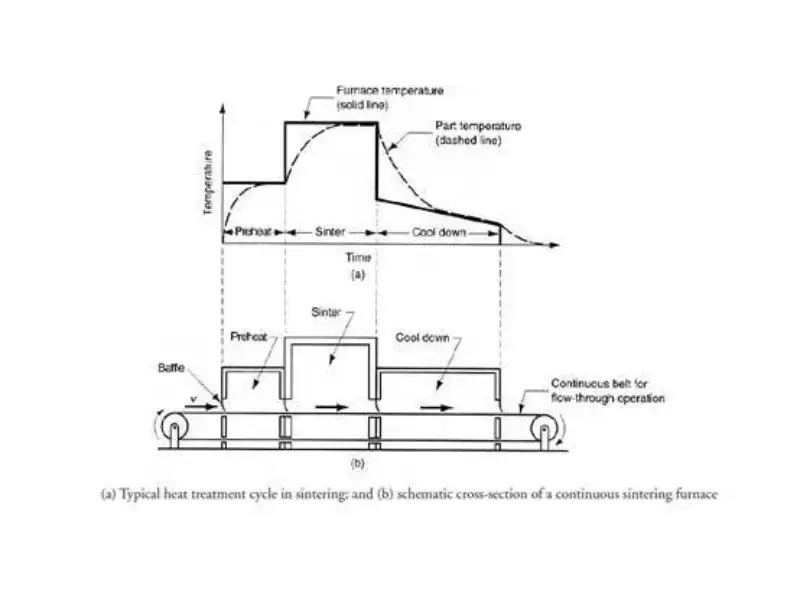

Advanced Powder Metallurgy Techniques & Applications | Precision Metal Forming Precision metal forming has been significantly advanced by the development of powder-based manufacturing technologies. This process has revolutionized the manufacturing industry by enabling the production of complex and high-performance components with exceptional precision and efficiency. This article explores the advanced techniques and applications of this […]

Section 1: Introduction to Metal Sintering Metal sintering is a pivotal process in manufacturing precision components, utilizing powdered metals to create durable and complex parts. This article explores the various facets of metal sintering, highlighting its applications, benefits, and the expert metal sintering services offered by Welleshaft as a leading global supplier in this field. […]

High-Performance Sintered Bearings | Durable & Efficient Solutions for All Applications In today’s demanding industrial environment, selecting the right bearing type is crucial to ensure the reliability, efficiency, and longevity of machinery and equipment. High-performance sintered bearings are among the most sought-after solutions, known for their durability, self-lubricating properties, and versatility. In this article, we’ll […]