1.Bevel Gear Maintenance Best Practices: How to Maximize Gear Lifespan

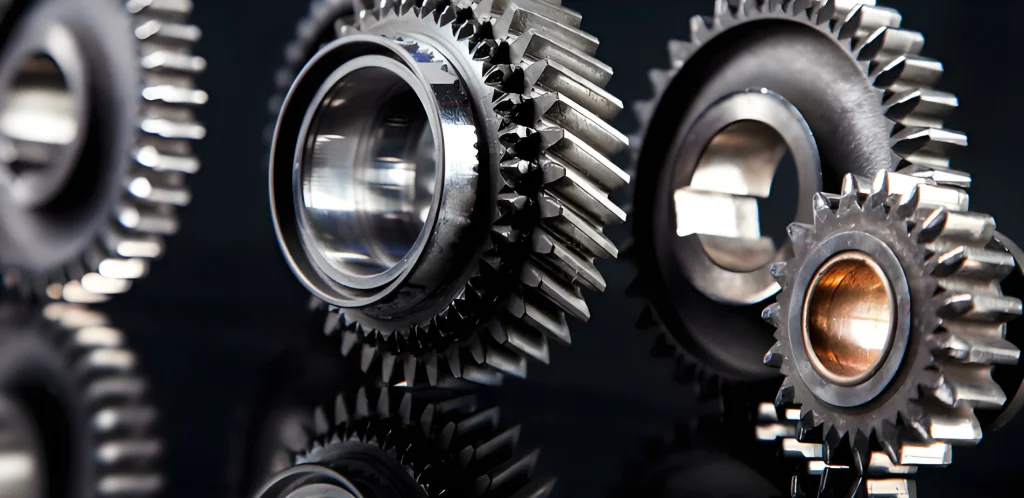

Many industrial machinery owners invest in precision bevel gear production oder custom bevel gear manufacturing, yet fail to achieve the expected lifespan because they don’t follow proper Bevel Gear Maintenance Best Practices for industrial machinery. Whether you work with spiral bevel gear manufacturing, straight bevel gear manufacturing, or CNC bevel gear production, routine lubrication, precise alignment, and thorough inspection are essential to avoid downtime and costly repairs. In this guide, Welleshaft’s engineers share Bevel Gear Maintenance Best Practices to help you maintain bevel gears for long-term reliability and performance.

2.Why Bevel Gear Maintenance Is Critical for Industrial Machinery

Bevel gears are used in high-torque applications such as manufacturing systems, heavy-duty equipment, and automotive drivetrains. Without preventive maintenance for bevel gears in manufacturing systems, issues like misalignment, tooth wear, and overheating can occur. Regular industrial bevel gear inspection ensures early detection of wear and prevents expensive failures.

3.How Often Should Bevel Gears Be Inspected and Maintained?

Inspection frequency depends on application load and operating environment:

- Heavy-Duty Equipment:Weekly visual checks and monthly detailed inspections.

- Manufacturing Systems:Monthly inspections plus quarterly alignment checks.

- Automotive Systems:Inspection every 5,000–10,000 km or as per service schedule.

(1) Bevel Gear Inspection and Maintenance for Machinery Reliability

Key inspection steps include:

- Checking for cracks, pitting, or chipped teeth.

- Measuring backlash with precision tools.

- Evaluating lubricant condition for contamination.

4.Proper Lubrication Process for Bevel Gear Longevity

Lubrication reduces friction and wear in bevel gear and pinion systems. Following the correct bevel gear maintenance and lubrication services process is crucial.

(1) Selecting the Right Lubricant

- Use gear oil suitable for torque, speed, and temperature conditions.

- For spiral miter gearsund zerol bevel gear setups, select lubricants with anti-wear additives.

(2)Lubrication Schedule

- Heavy-duty machinery: Every 250 operating hours.

- Manufacturing lines: Every 500 operating hours or per OEM guidelines.

(3) Avoiding Common Lubrication Mistakes

- Mixing different lubricant brands.

- Over-lubricating, which can cause overheating.

- Failing to filter contaminants from oil.

5.Bevel Gear Alignment and Maintenance for Smooth Operation

Alignment ensures that teeth mesh evenly, preventing premature wear.

(1)Alignment Process for CNC Bevel Gear Maintenance and Performance Optimization

- Inspect shaft parallelism and angular alignment.

- Use laser alignment tools for accuracy.

- Adjust mounting bolts to achieve precise meshing.

(2)Signs of Misalignment

- Uneven wear patterns on gear teeth.

- Excessive vibration during operation.

- Noise under load conditions.

6.Extending the Lifespan of Bevel Gears Through Preventive Maintenance

Following long-term bevel gear maintenance for heavy-duty equipment best practices can double gear lifespan.

(1)Affordable Bevel Gear Repair and Maintenance Solutions

- Replace worn bearings before they damage gears.

- Regrind or lap gear teeth to restore contact pattern.

- Schedule inspections with bevel gear quality inspection

8.Frequently Asked Questions

(1) What are the best practices for maintaining bevel gears in industrial machinery?

Lubricate regularly, align precisely, and inspect frequently to detect wear early.

(2)How do I extend the lifespan of my bevel gears through maintenance?

Follow preventive maintenance schedules, keep lubrication clean, and maintain alignment.

(3)What is the proper lubrication process for bevel gears?

Use the manufacturer-recommended oil, check levels frequently, and avoid contamination.

(4) How do I know if my bevel gears need maintenance or replacement?

Look for noise, vibration, or visible damage; confirm with a bevel gear inspection service.

Welleshaft is a quality control engineer with over 5 years of experience in bevel gears manufacturing, bevel gear machining servicesund industrial bevel gear inspection. He has worked with clients in heavy machinery, automotive, and manufacturing sectors to develop bevel gear servicing and upkeep for automotive systems that maximize performance and reliability.