1.Custom Bevel Gear Solutions for Automotive Drivetrains

Automotive manufacturers seeking high-performance Bevel Gears in Automotive Applications need reliable solutions for custom bevel gear manufacturing und precision bevel gear production. From straight bevel gears zu spiral bevel gear manufacturing, selecting the right supplier ensures durable, efficient, and precise drivetrain components. Professional bevel gear inspection service und CNC bevel gear production help OEMs reduce downtime, minimize rework, and confidently integrate bevel gears for car transmission and differential systems.

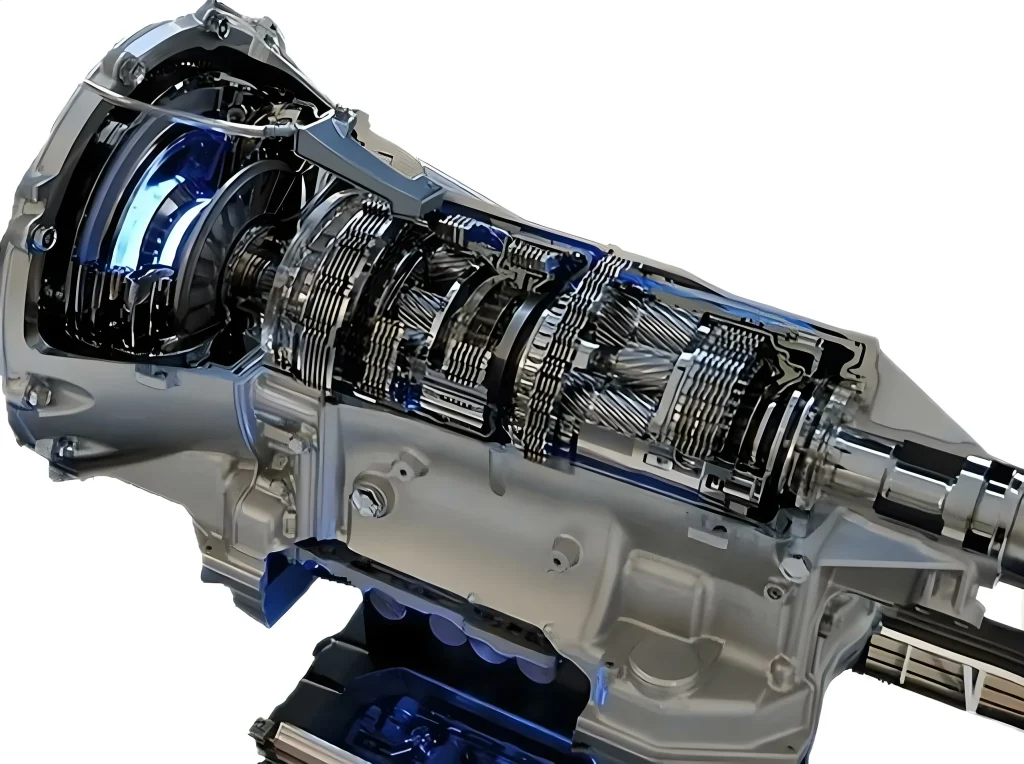

2. Why Bevel Gears Are Critical in Automotive Drivetrain Systems

- Bevel gears transfer torque between intersecting shafts in car transmission and differential systems.

- Essential for precision bevel gears for electric vehicle (EV) drivetrainsund high-performance bevel gears for automotive applications.

(1)Performance Challenges Addressed by Industrial Bevel Gear Inspection

- Misalignment, wear, and vibration issues

- Reduced efficiency under high torque

- Bevel gear quality inspectionund industrial bevel gear inspection ensures reliability

3. Bevel Gear Manufacturing Process for Automotive Applications

(1) Material Selection for Custom Bevel Gears in Automotive Gearboxes

Alloy steels, hardened metals, and composites

Comparison table:

| Material | Strength | Durability | Noise Performance | Common Applications |

| Alloy Steel | High | High | Moderate | EV Drivetrains, High-Torque Cars |

| Hardened Steel | Moderate | High | Low | Standard Transmission |

| Composite | Low | Moderate | Very Low | Lightweight EV Systems |

(2) CNC Bevel Gear Production and Machining Services

- CNC bevel gears for automotive mechanical systems

- Straight bevel gear manufacturingvs spiral bevel gear manufacturing

- Ensures bevel gear assemblyaccuracy and high torque performance

(3) Heat Treatment and Surface Finishing

- Carburizing, nitriding, and polishing

- Improves lifespan for bevel gears for automotive drivetrain systems

(4) Bevel Gear Quality Inspection and Industrial Bevel Gear Inspection

- Dimensional checks, gear profile, hardness testing

- Supports bevel gear inspection serviceund precision bevel gear production

- Ensures OEM-grade reliability for custom bevel gears for automotive gearboxes

(5) Assembly and Functional Testing

- Alignment verification for bevel gear and pinionsystems

- Torque and noise testing for spiral gearund straight bevel gears

- Guarantees high-performance bevel gears for automotive applications

4. Comparing Types of Bevel Gears for Automotive Drivetrains

| Gear Type | Torque Capacity | Noise | Manufacturing Complexity | Typische Anwendungen |

| Straight Bevel Gears | Medium | Moderate | Simple | Standard Transmission |

| Spiral Bevel Gears | High | Low | Complex | High-Performance Cars, EVs |

| Zerol Bevel Gear | High | Very Low | Medium | Quiet EV Drivetrains |

| Spiral Miter Gears | Medium | Low | Medium | Limited-Slip Differentials |

Helps OEMs decide which type to select based on performance vs cost.

6. Frequently Asked Questions

1: What are bevel gears used for in automotive applications?

They enable smooth torque transfer in transmission, differential, and EV drivetrain systems.

2: How do bevel gears improve the performance of automotive drivetrains?

By reducing energy loss, minimizing noise, and improving torque distribution.

3: What type of bevel gears are used in electric vehicle drivetrains?

Precision bevel gears for EV drivetrains, spiral bevel gearsund zerol bevel gears are commonly used.

4: How do I choose the right bevel gears for automotive applications?

Consider load, speed, torque requirements, materials, and whether a custom bevel gear solution is needed.

5: What is the manufacturing process for bevel gears in automotive systems?

Includes material selection, CNC machining, heat treatment, inspection, and functional testing.

With over 10 years of experience in bevel gears manufacturing, CNC bevel gear production, and industrial bevel gear inspection, Welleshaft engineers provide OEMs with reliable custom bevel gears for automotive gearboxes und high-performance bevel gears for automotive applications, ensuring durable, efficient, and precise drivetrain systems.