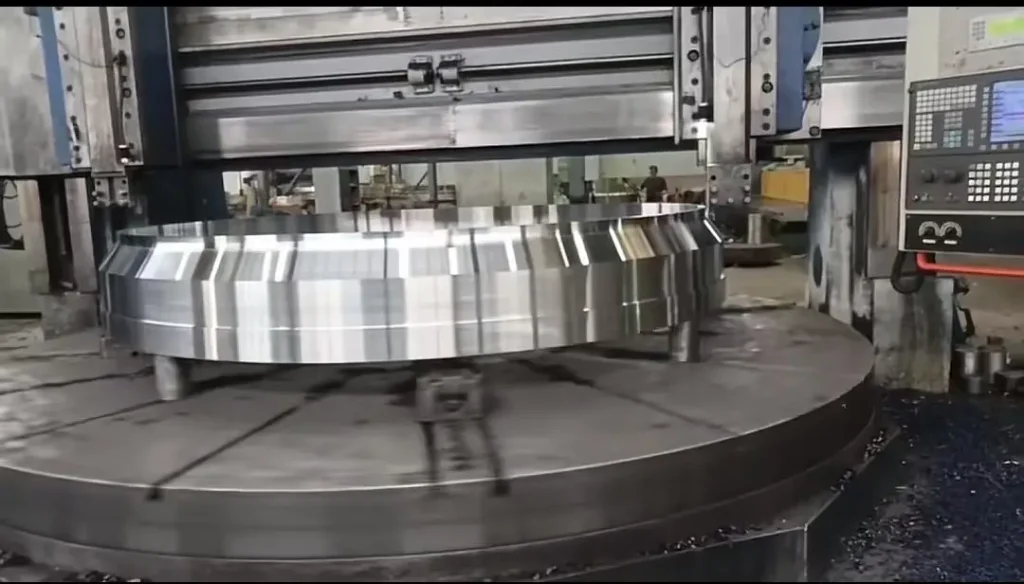

Top-Quality Forged Flanges | Durable Solutions for Industrial Applications Forged flanges play an essential role in connecting pipes, valves, pumps, and other components to form complete piping systems. Their durability, strength, and ability to withstand high pressures make them indispensable in industries such as oil & gas, petrochemicals, power generation, and more. In this article, […]

High-Quality Forged Steel Components | Durable Custom Forging Solutions Forged steel components are the backbone of various industries, from automotive to aerospace, due to their unmatched strength, durability, and reliability. Choosing High-Quality Forged Steel Components requires understanding the material’s properties and manufacturing processes to make informed decisions for your applications. In this article, we will […]

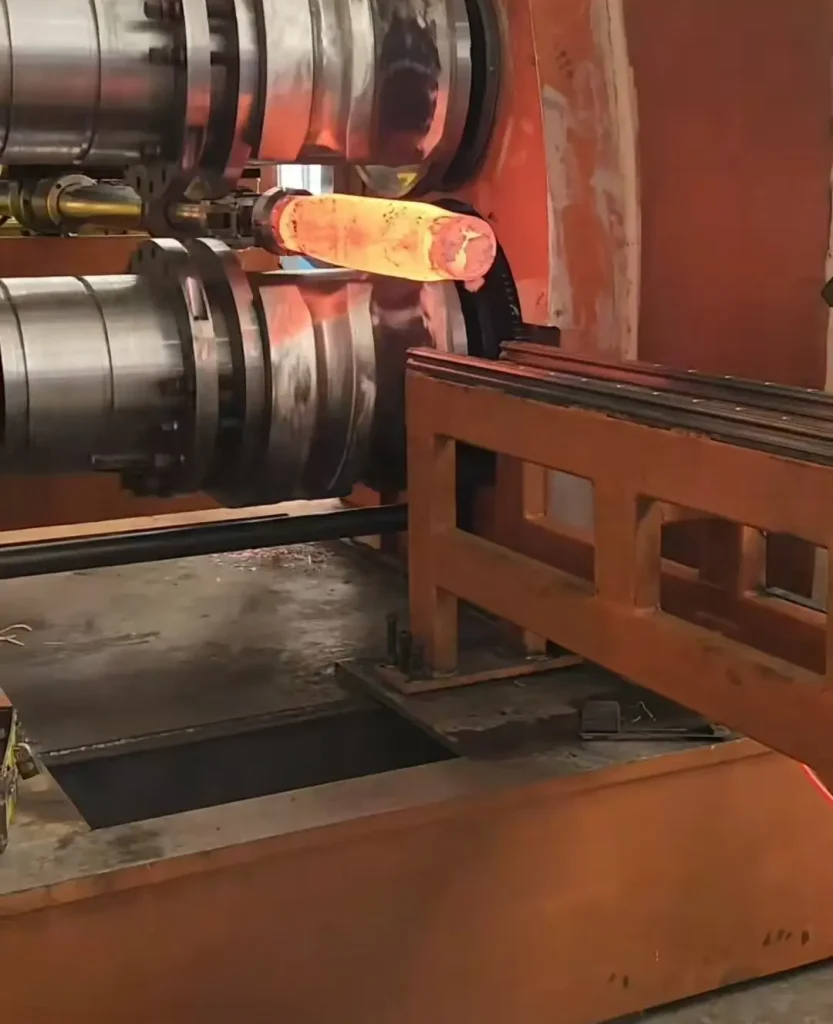

Impression Die Forging: High-Precision Forging Solutions for Superior Quality Components In the realm of metalworking, forging processes are crucial for producing high-strength components that meet stringent industry standards. Among these processes, impression die forging stands out for its ability to create intricate and high-quality parts. This article delves into impression die forging, its advantages, and […]

Precision Robotic Component Manufacturing | High-Quality Parts for Automation In today’s highly automated world, the demand for precision and high-quality robotic components is increasing rapidly. Whether for industrial automation, medical robotics, or advanced manufacturing systems, robotic parts must meet stringent requirements to ensure performance, longevity, and adaptability. This article delves into the importance of precision […]

Celebrate National Day with Welleshaft Dear Valued Customers, As we celebrate the National Day, the WELLE team extends our best wishes for peace, prosperity, and continued success to you and your team. This holiday marks a time of pride and progress, and we are honored to support your business with our high-quality Precision Machining and […]

High-Precision Aluminum Forging | Expert Forging Solutions for Durable Components Aluminum forging plays a pivotal role in modern manufacturing, providing high-strength, lightweight components used across various industries, from automotive to aerospace. High-precision aluminum forging ensures the reliability and durability of these components, making them a preferred choice over alternative materials. In this article, we will […]

Cutting-Edge Innovations in Smart Manufacturing & Industrial Automation The China International Industry Fair (CIIF) 2024 is set to be a landmark event in the global industrial sector, showcasing cutting-edge technologies and innovations that are shaping the future of manufacturing. This year’s focus is on smart manufacturing, industrial automation, and several other key areas that are driving the modernization […]

Precision Swaging Services | High-Quality Swaging Solutions for Custom Components Swaging is a vital metal-forming process widely used in industries where precision, durability, and cost-effectiveness are essential. Whether in aerospace, automotive, or medical applications, swaging delivers components that meet the highest standards of accuracy and strength. This article explores the swaging process, tools, and applications […]

Forging Stainless Steel Components | Precision & Custom Solutions Forging stainless steel components demands a deep understanding of the material’s properties, specialized techniques, and precision to create products that meet diverse industry standards. Industries highly value stainless steel for its strength, corrosion resistance, and aesthetic appeal. In this article, we explore the forging process, highlight […]

High-Quality Bronze Forging Services | Expert Bronze Forged Components Bronze forging is a sophisticated process that transforms raw bronze into high-quality, precision-engineered components. This technique is essential for producing durable and reliable parts used across various industries. In this article, we explore the intricacies of bronze forging, including the types of bronze used, the forging […]