Can You Explain What an ACME Threaded Rod Is?

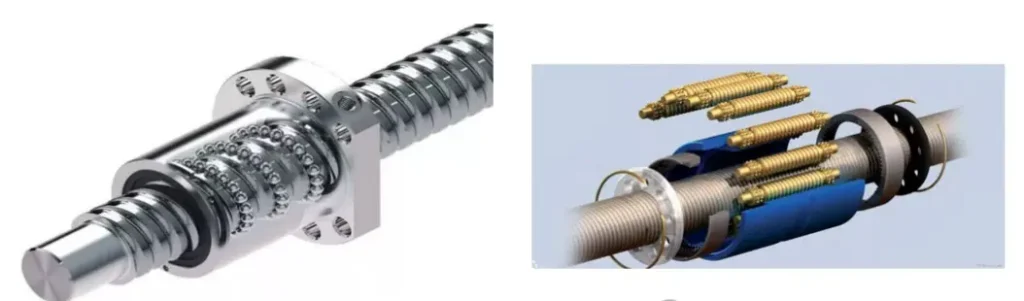

An ACME threaded rod features a trapezoidal thread profile with a 29-degree angle, delivering smooth, precise linear motion while offering superior strength and efficiency compared to standard threaded rods. Available as ACME threaded rods and nuts, including metric and coarse options, these rods reduce friction, handle high loads, and ensure reliable performance in industrial machinery and precision motion systems, making them ideal for manufacturers and engineers.

What Does the Acronym ACME Represent in Thread Terminology?

ACME refers to a standardized thread profile for lead screws, nuts, and rods. It balances strength and efficiency, enabling smooth, reliable linear motion under high loads, making it ideal for industrial and precision applications.

Why Choose Brass ACME Threaded Rods?

Non-Sparking Properties

Brass ACME threaded rods are non-sparking, making them safe for flammable or explosive environments. Ideal for chemical plants, mining, and oil & gas, they provide reliable, precise performance in demanding industrial applications.

Corrosion Resistance

Brass ACME rods and nuts, though less corrosion-resistant than stainless steel, offer strong durability against moisture and chemicals. With protection, they provide long-lasting, precise performance in demanding industrial applications.

Precision and Strength

From 1/2 inch ACME threaded rods to large threaded rod options, the trapezoidal ACME profile delivers smooth, precise motion while handling significant loads. Renowned for their precision and strength, these rods are essential for machinery and automation, and brass ACME rods add non-sparking reliability, making them ideal for suppliers and high-performance manufacturers.

Applications of Brass ACME Threaded Rods

Non-Sparking Environments

In high-risk industries like oil refineries, chemical plants, and mining operations, brass ACME threaded rods are crucial. Their non-sparking nature, combined with ACME threaded rod nuts, ensures safe, reliable operation in explosive atmospheres, preventing accidental ignition and supporting dependable industrial performance.

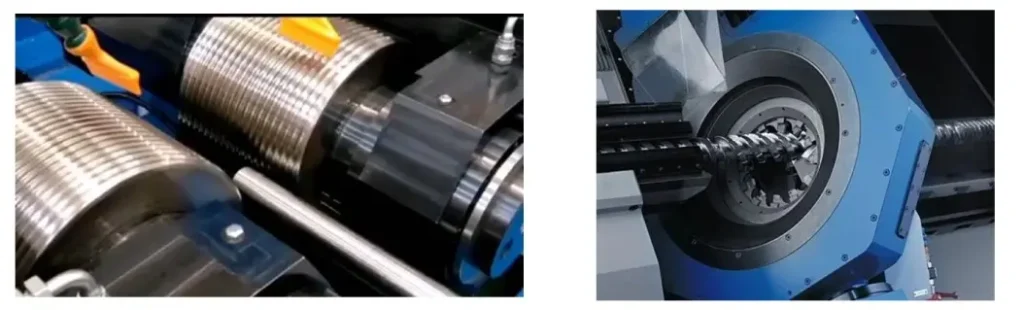

Machinery and Equipment

Brass ACME rods, widely used in ACME screw jacks, lead screws and nuts, and other mechanical systems, deliver smooth, precise linear motion and high load capacity. Their strength and trapezoidal ACME thread profile make them ideal for industrial automation, precision assembly lines, and machinery requiring reliable, accurate performance.

Industrial Settings

Brass ACME rods excel in general industrial environments, offering precision, strength, and non-sparking reliability. Whether used as threaded rods with nuts, partial threaded rods, or end fittings, they support machinery and automated systems, making them a versatile, trusted choice for engineers, procurement teams, and industrial applications.

What is the Difference Between ACME Thread and Standard Thread?

ACME threaded rods outperform standard threads thanks to their trapezoidal profile, higher load capacity, and smoother motion, making them ideal for screw rods, acme thread rods and nuts, and acme fasteners. Compare the key differences below:

| Feature | ACME Thread | Standard Thread |

| Profile | Trapezoidal | Triangular |

| Load Capacity | High | Moderate |

| Applications | Linear motion, lead screws | General fastening |

| Friction | Lower | Higher |

This comparison highlights why ACME threads are preferred in industrial automation, precision systems, and high-performance mechanical applications.

Brass ACME Thread Chart and Sizes

Selecting the right ACME threaded rod is crucial for smooth, reliable performance in machinery and linear motion systems. Buyers can refer to the simplified sizes chart below to choose acme threaded rod and nuts, screw rods, or metric ACME threaded rods based on load and application:

| Size | Thread Pitch | Applications |

| 1/2″ ACME | 10 TPI | Small machinery, jacks |

| 3/4″ ACME | 5 TPI | Medium-duty linear systems |

| 1″ ACME | 4 TPI | Heavy-duty industrial machinery |

| 1 1/2″ ACME | 3 TPI | Large threaded rod assemblies |

This chart simplifies selection, ensuring precise fit, optimal motion, and reliable performance across industrial, automation, and precision engineering projects.

Advantages and Disadvantages of Brass ACME Threads

Advantages

Brass ACME threaded rods combine non-sparking properties, high precision, and strong load-bearing capabilities, making them essential for ACME lead screws, motion control systems, and threaded rods with nuts. Their non-sparking nature ensures safety in sensitive environments, while the trapezoidal ACME thread profile delivers smooth, accurate linear motion and reliable performance under heavy loads. These features make brass ACME rods a dependable choice for industrial automation, precision machinery, and high-performance engineering projects.

Disadvantages

While brass ACME threaded rods offer good corrosion resistance, they are slightly less durable than stainless steel in highly corrosive environments. Additionally, the cost for dependable ACME threaded products can be higher compared to standard materials. However, the combination of precision, non-sparking safety, and strong load-bearing capabilities often outweighs the extra investment, making brass ACME rods a smart choice for industrial automation, motion control systems, and high-performance machinery where reliability and safety are paramount.

Difference Between ACME Thread and Trapezoidal Thread

While ACME threads and trapezoidal threads share a similar profile, ACME threads are specifically optimized for precision motion applications, delivering smooth, reliable linear movement in machinery, lead screws, and automation systems. In contrast, trapezoidal threads are often found in general-purpose rods offered by threaded rod manufacturers and are less critical for high-precision tasks. Choosing ACME threads ensures superior performance, reduced wear, and dependable operation in industrial and mechanical environments, making them a smart choice for engineers and procurement teams seeking high-quality, precision threaded rods

Why ACME Threads Are 29 Degrees

The 29-degree angle in ACME screw threads is engineered to strike the perfect balance between strength and machining ease, reducing friction while ensuring smooth, precise linear motion. This optimized design enhances load-bearing capacity and durability for ACME rods, acme precision threaded rods, and acme power screws, making them ideal for industrial machinery, automation systems, and high-performance motion control applications. By selecting ACME threads with this precise angle, engineers and procurement teams can achieve reliable, efficient operation while minimizing wear and maintenance.

Why Choose Welleshaft Brass ACME Threaded Rods for Precision Applications?

Welleshaft provides high-quality ACME threaded rodsand nuts, metric ACME threaded rods, and acme threaded rod near me options. Their rods are:

- Manufactured with precision for acme screw threads.

- Available in various sizes, including 1 inch ACME threaded rodand coarse threaded rod.

- Suitable for industrial machinery, linear motion systems, and custom applications.

By working with Welleshaft, engineers can source dependable ACME threaded products without worrying about supply disruptions or quality inconsistencies.

Brass ACME Threaded Rod FAQ

What Is a Brass ACME Threaded Rod Used For?

Used in screw rods, acme threaded rod and nut assemblies, and acme lead screws, brass ACME rods are perfect for linear motion applications, machinery, and non-sparking environments.

What Are the Advantages of Brass ACME Threads Over Steel?

- Non-sparking properties

- Excellent precision for ACME screw threads

- Reliable performance in industrial motion systems

How Do Brass ACME Threaded Rods Perform in Precision Motion Systems?

Paired with acme nuts, threaded rod distributors, or hex nuts, brass ACME rods ensure smooth, accurate linear motion, minimal wear, and high load capacity, outperforming traditional threaded rods or screw thread rods.

This blog was provided by the Trục giếng Engineering Team. Led by Mr. Zhang, our experts specialize in ACME threaded rods, precision motion systems, and industrial automation solutions, delivering reliable engineering insights and high-quality products to global clients.