Unistrut Rollers Manufacturing: Your Ultimate Guide to Choosing the Right Roller

Unistrut rollers play a crucial role in various industrial and DIY applications where movement along Unistrut channels is required. Whether you’re looking to build a sliding door, a heavy-duty trolley system, or need rollers for pipework, understanding the types, specifications, and where to find them is essential. In this comprehensive guide, we explore everything you need to know about Unistrut rollers and where to find them for sale.

Understanding Unistrut Rollers

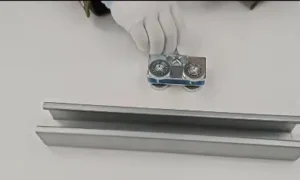

Unistrut rollers are specially designed to fit into Unistrut channels, providing smooth movement and support for various loads. They come in different types and configurations to suit specific applications, from light-duty residential projects to heavy-duty industrial settings. These rollers typically feature durable materials like steel or nylon, ensuring longevity and reliability in demanding environments.

Types of Unistrut Rollers:

1. Standard Rollers:

These are the most common type, suitable for general applications where moderate load capacity and smooth movement are required.

2. Heavy-Duty Rollers:

Designed for applications involving heavier loads or frequent use, heavy-duty rollers are built to withstand greater stress and provide long-term durability.

3. Pipe Rollers:

Specifically designed for supporting pipes within Unistrut channels, these rollers prevent damage and ensure stability during movement or adjustments.

4. Trolley Rollers:

Used in trolley systems that run along Unistrut channels, these rollers are pivotal in creating mobile structures such as sliding doors, tool carts, and material handling systems.

Key Considerations When Choosing Unistrut Rollers

When selecting Unistrut rollers, several factors should influence your decision:

1.Load Capacity:

Determine the maximum load the rollers will need to support. Heavy-duty rollers are essential for larger loads or frequent use scenarios.

2.Material:

Consider the material of the rollers based on your application needs. Steel rollers offer strength and durability, while nylon rollers provide smooth and quiet operation.

3.Channel Compatibility:

Ensure the rollers are compatible with the specific size and type of Unistrut channel you are using. This compatibility ensures proper fit and functionality. –

4.Environment:

Evaluate the environmental conditions where the rollers will be used. Factors such as temperature extremes, moisture, and chemical exposure may influence your material choice.

Where to Buy Unistrut Rollers

Finding the right Unistrut rollers for your project involves choosing a reputable supplier that offers quality products and reliable service. Here are some popular options:

1. Hardware Stores:

Local hardware stores often carry a selection of Unistrut rollers, including standard and heavy-duty varieties. Stores like Home Depot and Bunnings Warehouse are known for their comprehensive inventory.

2. Online Retailers:

Websites like Amazon, Grainger, and specialized industrial suppliers offer a wide range of Unistrut rollers with detailed specifications and customer reviews. This option provides convenient shopping and delivery to your doorstep.

3. Manufacturer Direct:

Some manufacturers of Unistrut systems and components sell rollers directly through their websites(Welleshaft) or authorized distributors. This ensures product authenticity and often provides technical support for your specific application needs.

4. Specialized Industrial Suppliers:

Industrial supply companies(Jinan Welle Metal Products company) that focus on material handling, construction, or engineering solutions often stock a variety of Unistrut components, including rollers. They can provide expert advice and tailored solutions for complex projects.

DIY Projects with Unistrut Rollers

For DIY enthusiasts and small-scale projects, Unistrut rollers offer versatility and ease of assembly. Here are a few popular DIY applications:

1.Sliding Doors:

Create smooth-sliding doors for workshops, garages, or industrial spaces using Unistrut rollers and tracks.

2.Tool Carts and Workstations:

Build customized tool carts or mobile workstations that can move along Unistrut channels, providing flexibility and organization in your workspace.

3.Material Handling Trolleys:

Construct heavy-duty trolleys for transporting materials within warehouses or industrial facilities, utilizing Unistrut rollers for smooth movement and robust support.

Conclusion

Unistrut rollers are indispensable components in a wide range of applications, from industrial settings to DIY projects. Choosing the right roller involves considering load capacities, materials, and compatibility with Unistrut channels. Whether you’re looking for standard rollers, heavy-duty options, or specialized pipe rollers, reputable suppliers and online retailers offer a variety of choices to suit your needs. By understanding these factors and exploring the available options, you can confidently select Unistrut rollers that ensure efficiency, durability, and smooth operation in your projects.