Sand Casting vs. Die Casting vs. Investment Casting: Choosing the Right Process for Your Parts Introduction: Understanding the Three Key Casting Methods Casting plays a pivotal role in modern manufacturing, especially for producing complex metal parts at scale—and Welleshaft’s custom metal casting services ensure each solution is tailored to your design, material, and volume requirements.. […]

Category Archives: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

1.What is Sandblasted Metal – Basics of Metal Sand Blasting | Welleshaft Metal sandblasting is a common surface treatment used in many industries like automotive, marine, and construction. Here at Welleshaft, we explain what sandblast is, how to sandblast metal, and why a good sandblasted metal finish matters for your project. 2.What is Sandblasting Metal and […]

1.Advantages of Zinc Die Casting | Zinc Part Design Guide by Welleshaft Picking Wooting 80HE zinc or plastic isn’t just about looks—it affects build, feel, and lifespan. Welleshaft makes zinc die cast parts and custom zinc alloy housings for electronics. This guide explores key Zinc Die Cast Advantages and shows why alloys with zinc often […]

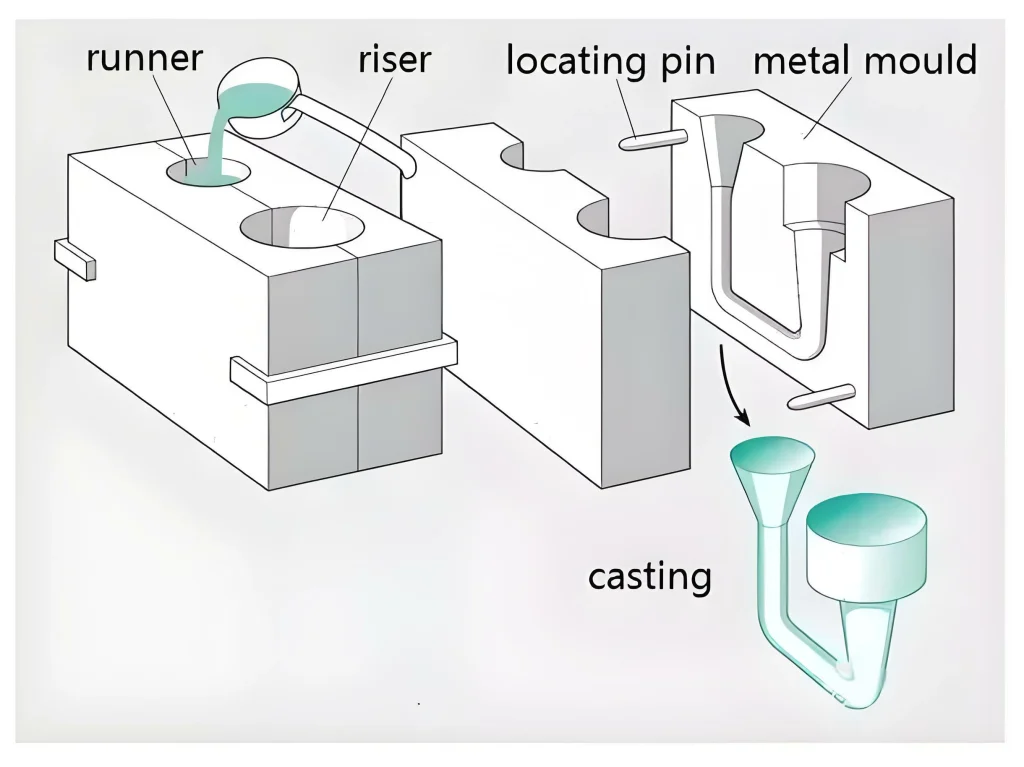

The Crucial Role of Gating and Degating in Zinc Casting | Welleshaft 1.Introduction to Degating and Casting Gating in Zinc Die Casting In high-pressure zinc die casting, degating means removing bits like runners, gate in casting, and overflows that don’t belong on the finished part. These come from the casting gating system that guides molten […]

1.Zinc Alloys for Die Cast Manufacturing | Welleshaft Die Casting with Zinc Alloys is widely used across industries ’round the world for its strength, reliability, and ability to take on all sorts of shapes. At Welleshaft, we help folks get their zinc die casting needs met with parts that look good and hold up—whether in […]

1.What to Know About Zinc Alloys for Casting | Welleshaft Zinc alloys stay a reliable pick when it comes to precision casting. Thanks to their low melting temp, resistance to rust, and shaping flexibility, zinc alloy casting holds its ground in today’s factories. What is zinc alloy material? At Welleshaft, we build custom cast zinc […]

1.Why Zinc Die Casting Stands Out for Durable Parts Many engineers and manufacturers pick zinc die casting because of its great zinc strength, accuracy, and affordability. At Welleshaft, we work with casting zinc and zinc alloy die casting daily, delivering reliable zinc die casting parts across various fields. This article explains how strong is zinc, dives into key properties […]

1.What Is ZAMAK? The Ultimate Guide to Zinc Die Casting Alloys | Welleshaft ZAMAK, also called ZAMAC, is a long-used family of zinc alloys that changed high-pressure die casting when it came on the scene in the 1920s. Here at Welleshaft, your go-to zinc die cast manufacturer, we work hands-on with zamak casting across industries needing tough […]

Does Zinc Die Cast Rust? 1.Does Zinc Alloy Rust Over Time? Choosing material for die cast metal parts means asking—does zinc alloy rust? People often worry about how parts hold up once they hit air, water, or chemicals. Welleshaft’s zinc alloy parts resist wear that steel can’t match—without turning into red rust. 2.What Is Zinc Alloy […]