1.Busbar Applications Across Industries: Power Distribution, Data Centers & More

Busbar products are critical in modern electrical systems, enabling safe, efficient, and scalable power distribution. From copper busbars in manufacturing plants to custom busbar systems in data centers and insulated busbars in renewable energy installations, their versatility makes them essential across industries. Yet many businesses are still unaware of the wide range of Busbar Applications Across Industries, the differences between aluminum and copper busbar solutions, and how busbar components enhance performance in diverse environments.

This article explores how busbar systems are used in power distribution, data centers, renewable energy, manufacturing, transportation, and commercial buildings—helping you answer the key question: What industries use busbar products the most, and why?

2.What Are Busbar Products and Systems?

Busbar systems are metallic conductors designed to distribute electricity efficiently within electrical panels, substations, and large-scale infrastructure. Typically manufactured from copper busbars or aluminum busbars, they replace traditional cabling in many high-power applications.

Key types of busbar products include:

1.Copper busbar – High conductivity and durability, widely used in data centers and industrial plants.

2.Aluminum busbar – Lightweight and cost-effective, suitable for large-scale distribution.

3.Insulated busbar – Designed for safety in compact or high-density installations.

4.Busbar trunking systems – Modular solutions for flexible layouts in buildings and factories.

5.Custom busbar systems – Tailored for unique applications in telecom, renewable energy, and smart factories.

3.Why Industries Depend on Busbar Systems

Compared to cables, busbar products offer:

1.Higher current-carrying capacity with reduced energy loss.

2.Compact design for space-limited facilities like data centers.

3.Modularity for easy expansion in factories and commercial buildings.

4.Safety with better heat dissipation and insulation.

5.Reliability in harsh industrial environments.

This makes them indispensable across industries where efficiency, reliability, and scalability are critical.

4.Busbar Applications Across Key Industries

(1)Data Centers and Telecom

Busbar solutions for data center electrical infrastructure ensure uninterrupted power delivery to servers, cooling systems, and backup power units.

1.Benefits: Scalability, modularity, and reduced downtime.

2.Common setups: Insulated busbar trunking with custom layouts for hot-aisle/cold-aisle containment.

3.Industry insight: Custom busbar systems for telecom and data centers reduce installation complexity and improve load balancing.

(2)Manufacturing Plants and Industrial Facilities

Industrial busbar products for manufacturing plants power heavy machinery, robotic systems, and high-capacity motors.

1.Copper busbars are preferred due to durability and conductivity.

2.Busbar manufacturing innovations include prefabricated components for faster setup.

3.Durable busbar solutions for harsh industrial environments withstand high temperatures, vibration, and dust.

(3)Renewable Energy Systems

Busbar products for renewable energy applications are essential in solar farms, wind turbines, and battery storage systems.

1.Aluminum busbars are often used due to cost-effectiveness in large arrays.

2.Insulated busbars ensure safe operation in compact inverter cabinets.

3.Custom busbar designs integrate with hybrid energy storage systems.

(4)Commercial Buildings and Smart Factories

Busbar products suppliers for commercial buildings support lighting, HVAC, and electrical panels.

1.Busbar trunking systems make retrofitting easier in high-rise buildings.

2.Smart busbar solutions integrate with IoT sensors for monitoring and energy optimization.

(5)Transportation and Infrastructure

Busbar products for electrical panels in the transportation sector power trains, electric buses, and metro systems.

1.Copper busbars are used in high-current traction systems.

2.Insulated busbars prevent electrical faults in compact vehicles.

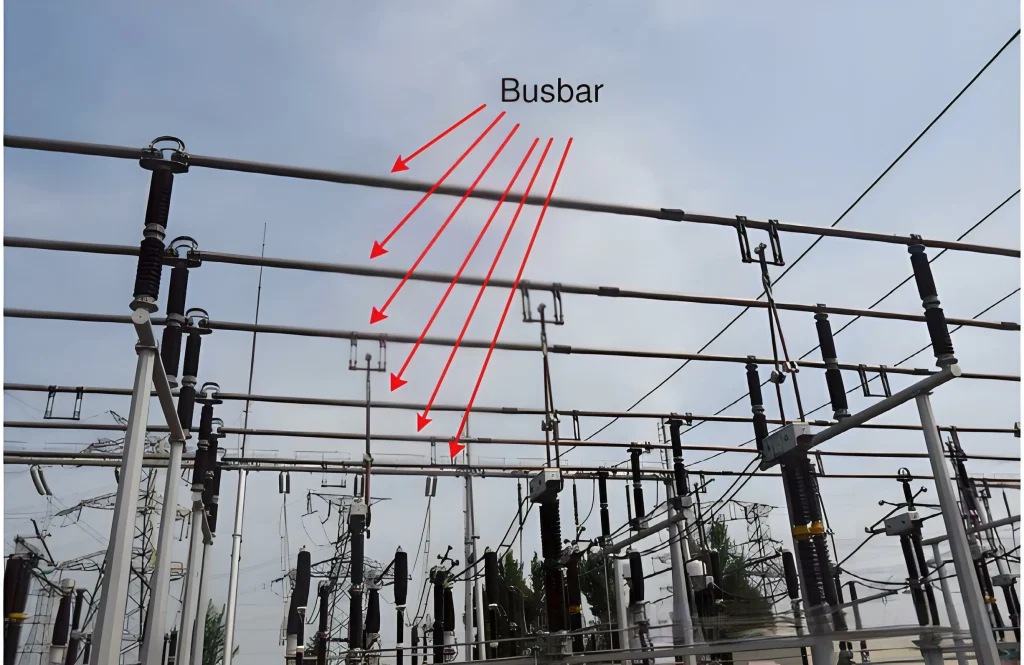

(6)High-Capacity Power Grids

Busbar products designed for high-capacity power grids handle large volumes of electricity in substations.

1.Copper and aluminum busbars balance cost and conductivity.

2.Custom busbar solutions are engineered for high-voltage transmission.

5.Choosing the Right Busbar for Your Industry

When selecting busbar products, consider:

1.Material: Copper vs. aluminum depending on conductivity vs. cost.

2.Environment: Insulated busbars for safety in compact or harsh conditions.

3.Scalability: Modular trunking systems for facilities expecting growth.

4.การปรับแต่ง: Tailored solutions for telecom, renewable energy, or smart factories.

6.Maintenance and Standards for Busbar Products

(1)Maintenance

1.Regular thermal imaging to detect hotspots.

2.Dust cleaning in industrial plants.

3.Tightening connections to avoid resistance buildup.

(2)Standards

What standards apply to busbar products in different industries?

1.IEC 61439 – Low-voltage switchgear and control gear assemblies.

2.IEEE standards – Electrical busbar systems.

3.UL certification – Safety requirements in North America.

7.People Also Ask

(1)What industries use busbar products the most?

Data centers, manufacturing plants, renewable energy, commercial buildings, transportation, and power grids.

(2)Can busbar products improve energy efficiency in factories?

Yes, by reducing resistive losses and integrating monitoring systems.

(3)How do busbar applications differ between industries?

Data centers focus on modularity, factories prioritize durability, and renewable systems need scalability.

This article was written by a quality engineer from เวลเลชาฟท์, with 5+ years of experience in electrical system audits, factory inspections, and industrial quality control. Welle specializes in third-party inspection services for manufacturing and electrical products, helping global clients ensure compliance, safety, and reliability in every project.