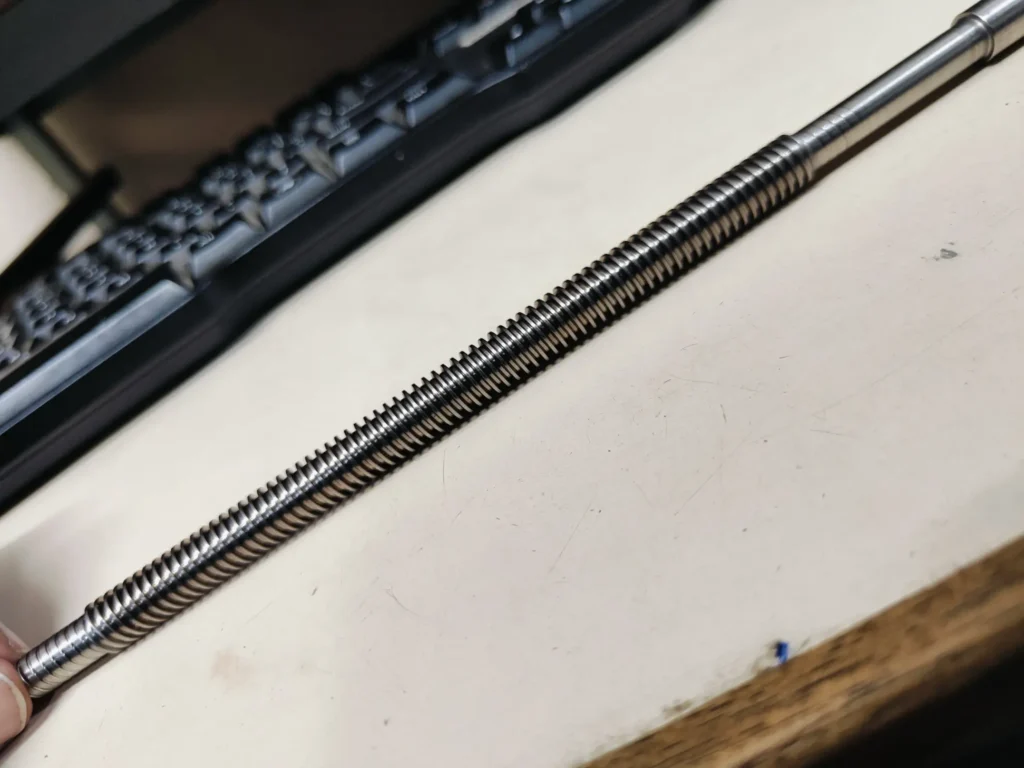

When it comes to precision engineering and mechanical design, the stainless steel ACME rod is a go-to solution for many applications. Known for its durability and resistance to corrosion, this versatile component is essential in various industries. In this article, we will explore the features, advantages, and applications of stainless steel ACME rods, and why Welleshaft is your trusted global supplier for these high-quality components.

What is an ACME Threaded Rod?

An ACME threaded rod is a type of screw or rod that features a trapezoidal thread profile. TEngineers originally developed the ACME thread design—with its 29-degree angle—to create strong, efficient threads for linear motion applications. This design delivers robust and reliable performance compared to other threading systems.

What Does ACME Stand for in Threads?

Engineers didn’t assign a specific full form to the term “ACME”; instead, they used it to represent a standardized thread profile. They originally named it for its intended use in engineering applications where high performance was essential. Industry professionals widely adopt the ACME thread profile for its strength and durability, especially in demanding environments.

Stainless Steel ACME Rod: Benefits and Applications

Corrosion Resistance

Stainless steel ACME rods offer a key advantage with their exceptional resistance to corrosion. Engineers choose stainless steel for its ability to withstand harsh environments, including exposure to moisture, chemicals, and extreme conditions. This corrosion resistance extends the rod’s lifespan and reduces maintenance needs.

Precision Engineering

ACME threaded rods are designed for precision. The trapezoidal thread profile allows for smooth and accurate linear motion, which is crucial in applications like lead screws, jacks, and other machinery components. Stainless steel enhances this precision by providing a stable and reliable threading system.

Versatility in Applications

The versatility of stainless steel ACME rods makes them suitable for a wide range of applications. From aerospace and automotive industries to manufacturing and robotics, these rods offer reliable performance across various sectors. The robust nature of stainless steel ensures that the rods can handle high loads and stresses, making them suitable for heavy-duty applications.

What is the Difference Between ACME Thread and Standard Thread?

ACME threads differ from standard threads in several key ways:

- Thread Profile:ACME threads have a trapezoidal profile, while standard threads are typically triangular. The trapezoidal shape provides better load distribution and less friction.

- Strength: The ACME thread’s design allows for higher strength and durability compared to standard threads.

- Applications:ACME threads are often used in linear motion applications, whereas standard threads are used in a variety of general fastening applications.

ACME Thread Chart and Sizes

Understanding the various sizes and types of ACME threads is crucial for selecting the right rod for your needs. The ACME thread chart provides information on different thread sizes, pitch, and diameter, which helps in identifying the appropriate rod for specific applications.

Common Sizes

3/4″ ACME Threaded Rod: Popular for medium-duty applications.

1/2″ ACME Threaded Rod: Often used in smaller machinery and equipment.

1″ ACME Threaded Rod: Suitable for heavy-duty applications requiring greater strength.

Acme Thread Angle

The ACME thread angle is set at 29 degrees, which provides a balance between strength and ease of machining. This angle is optimized for efficient power transmission and durability.

Difference Between ACME Thread and Trapezoidal Thread

While both ACME and trapezoidal threads have a similar profile, the key differences lie in their applications and precision. ACME threads are designed for more precise motion control, while trapezoidal threads are often used in more general-purpose applications.

Advantages and Disadvantages of ACME Threads

Advantages

- Durability: ACME threads are highly durable and can withstand significant loads.

- Corrosion Resistance: Stainless steel ACME rods offer excellent resistance to corrosion, extending their lifespan.

- Precision:The ACME thread profile allows for accurate and smooth linear motion.

Disadvantages

- Cost: Stainless steel ACME rods can be more expensive than other materials.

- Complexity:The manufacturing process for ACME threads is more complex compared to standard threads.

Why ACME Threads are 29 Degrees

The 29-degree angle of ACME threads is chosen for its optimal balance between strength and ease of machining. This angle provides efficient power transmission and ensures that the threads can handle significant loads without excessive wear.

Welleshaft: Your Trusted Supplier for Stainless Steel ACME Rods

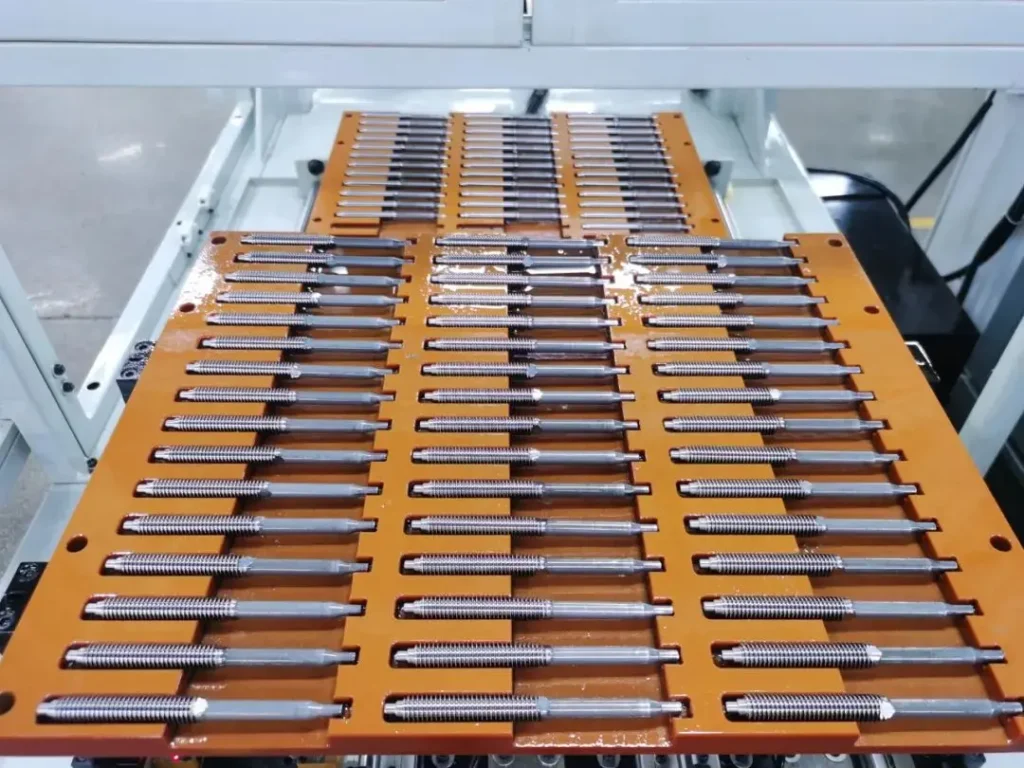

When it comes to sourcing high-quality stainless steel ACME rods, look no further than Welleshaft. As a leading global supplier and contract manufacturer, Welleshaft offers a wide range of ACME threaded products to meet your specific needs. Their commitment to quality and precision ensures that you receive only the best components for your applications.

Whether you need a stainless steel ACME rod near you or specialized ACME precision threaded rods, Welleshaft is your go-to source. Their extensive experience and expertise in manufacturing ACME threaded rods make them a trusted partner for engineers and manufacturers worldwide.

Conclusion

The stainless steel ACME rod is an essential component for various industrial and engineering applications, offering exceptional durability, precision, and corrosion resistance. Understanding the features and advantages of ACME threads helps in selecting the right rod for your needs. For high-quality ACME threaded products, Welleshaft stands out as the trusted global supplier and contract manufacturer, delivering excellence in every component.

For more information on stainless steel ACME rods and other precision engineering components, visit Welleshaft and explore their extensive range of products.