Spline Shafts: Power Transmission and Precision

Introduction to Spline Shafts

In the realm of mechanical engineering,

spline shafts play a pivotal role in transmitting power efficiently across various systems. These shafts are designed with grooves or teeth that mesh with complementary features on mating components, ensuring a secure and precise connection.

What are Spline Shafts?

These cylindrical mechanical components have ridges or teeth, called splines, machined along their length. The splines transmit torque while allowing axial movement or rotation.

Importance in Mechanical Systems

These components play a crucial role in applications requiring reliable power transmission and rotational integrity. They are widely used in automotive drivetrains, industrial machinery, aerospace systems, and more.

Types of Spline Shafts

Spline shafts come in several configurations tailored to specific applications:

Parallel Spline Shafts

Parallel shafts feature straight teeth cut parallel to the shaft’s axis, providing robust torque transmission capabilities. They are commonly used in heavy-duty applications such as gearboxes and hydraulic pumps.

Involute Spline Shafts

Involute splines use a tooth profile that enables smoother engagement and disengagement of mating components. This design improves efficiency and reduces wear, making them ideal for precision machinery and automotive differentials.

Helical Spline Shafts

Helical splines incorporate helical teeth that provide increased load-bearing capacity and reduced noise during operation. These components are favored in applications requiring high torque transmission and minimal vibration.

Components of Spline Shafts

These shafts consist of several essential components:

Spline Teeth

The spline teeth are the grooves or ridges machined along the shaft’s circumference. These teeth engage with complementary features on mating components, ensuring a secure connection while transmitting torque.

Spline Hubs

Spline hubs are components that fit onto shafts with external splines. They feature internal splines matching the shaft’s, enabling a mechanical connection that efficiently transfers power.

Spline Joints

Spline joints refer to the interfaces where splined shafts connect with other components. These joints must withstand axial and radial forces while accommodating rotational movement.

Design and Engineering Considerations

The design and engineering involve meticulous considerations:

Spline Shaft Standards

Various international standards govern spline shaft design, ensuring compatibility and interchangeability across different manufacturing environments. Standards such as ANSI B92.1 and ISO 4156 define tooth profiles and dimensions.

Material Selection for Spline Shafts

Manufacturers typically use high-strength materials such as Bosch Rexroth’s alloy steels, Thyssenkrupp’s stainless steels, and Saint-Gobain’s ceramics, depending on the application’s requirements. Material selection impacts durability, load-bearing capacity, and resistance to wear.

Applications of Spline Shafts

These components find diverse applications across industries:

Automotive Industry

In automobiles, these components are integral to transmission systems, enabling smooth gear shifts and efficient power delivery from the engine to the wheels.

Industrial Machinery

Industrial equipment such as machine tools and conveyors use these components to transmit rotational motion with high precision and reliability.

Aerospace Sector

In aerospace applications, actuators, landing gear mechanisms, and propulsion systems use these components, where lightweight yet durable parts are essential.

Advantages of Using Spline Shafts

Using these shafts offers several advantages over alternative mechanisms:

Efficient Power Transmission

These shafts minimize energy loss during power transmission, ensuring maximum efficiency in mechanical systems.

Reducing Slippage

The precise fit between these shafts and mating components reduces slippage, enhancing overall system reliability and performance.

Enhanced Torque Transmission

These shafts can transmit higher torque loads compared to other shaft mechanisms, making them suitable for heavy-duty applications.

Comparison with Other Shaft Mechanisms

Understanding the differences between these shafts and alternative mechanisms is crucial.

Shaft Key vs. Spline Shafts

Unlike shaft keys that transmit torque through friction and shear forces, these shafts distribute load more evenly along their length, reducing wear and maintenance needs.

Spline Shafts vs. Splined Hubs

While these shafts feature external teeth, splined hubs have internal teeth that engage with external splines on shafts. Each configuration offers distinct advantages depending on the application’s requirements.

Manufacturing Process of Spline Shafts

The manufacturing process involves specialized techniques.

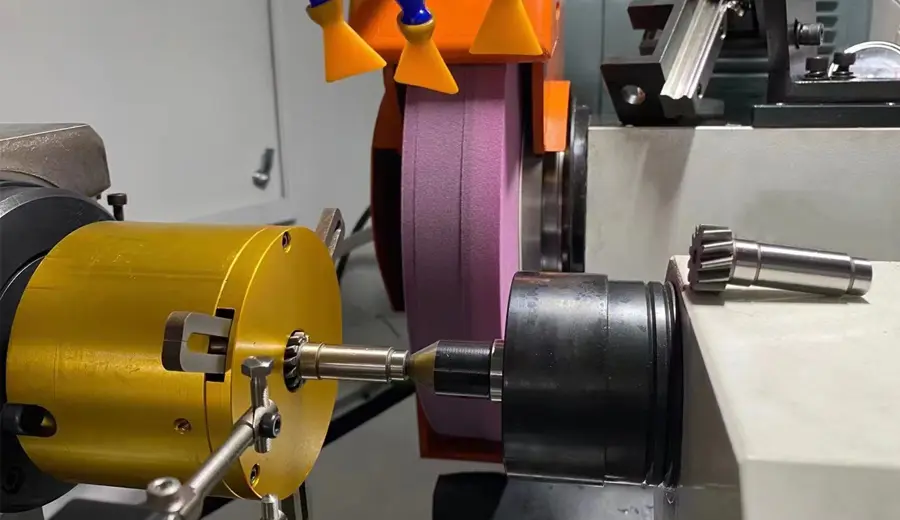

Machining Techniques

Spline shafts are typically machined using CNC (Computer Numerical Control) equipment to ensure precise tooth profiles and dimensional accuracy. Grinding and hobbing processes are common for achieving high-quality spline profiles.

Quality Control Measures

Stringent quality control measures, including dimensional inspections and material testing, ensure that spline shafts meet industry standards for durability and performance.

Maintenance and Troubleshooting

Proper maintenance is essential for optimizing spline shaft performance:

Common Issues with Spline Shafts

Issues such as wear on spline teeth, improper lubrication, and misalignment can affect shaft performance and longevity.

Maintenance Tips

Regular inspection, lubrication, and alignment checks are key to preventing premature wear and ensuring reliable operation.

Future Trends in Spline Shaft Technology

Advancements in spline shaft technology are driving innovation:

Innovations in Spline Design

Ongoing research focuses on developing advanced spline profiles and materials to enhance efficiency and durability in diverse applications.

Sustainability in Manufacturing

Efforts to reduce environmental impact through sustainable manufacturing practices are shaping the future of spline shaft production.

Conclusion

In conclusion, these components represent a critical part in modern mechanical systems, enabling efficient power transmission, precise motion control, and reliability across various industries. As technology advances, the evolution of their design and manufacturing continues to meet the demands for higher performance and sustainability.

FAQs

What is this shaft?

This mechanical component has ridges or teeth that transmit torque while allowing axial movement or rotation.

What is the purpose of a spline?

Splines create a secure and precise connection between mating parts, enabling efficient power transmission.

What are the advantages?

These shafts provide efficient power transmission, reduce slippage, and enhance torque transfer compared to other mechanisms.

What is the difference between a shaft key and this shaft?

A shaft key transmits torque through friction, while these shafts distribute the load evenly along their length, reducing wear and maintenance.

How are these shafts manufactured?

Manufacturers typically machine them using CNC equipment to ensure precise tooth profiles and follow rigorous quality control processes.