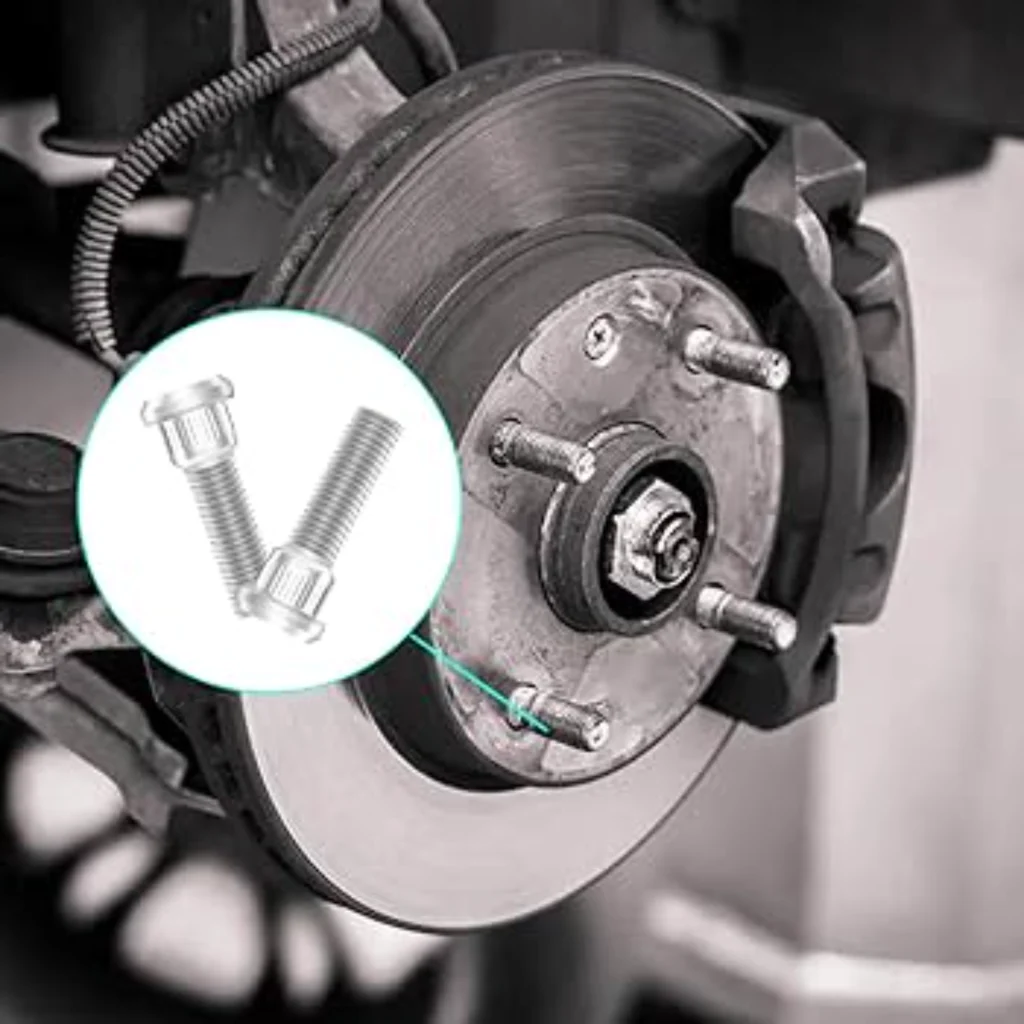

Strong, Reliable Wheel Bolts: Ensure Safe Travels Every Time

Section 1 Introduction

The safety of your vehicle hinges on many components, but one of the most critical, yet often overlooked, is the humble wheel bolt. These small, threaded fasteners are responsible for securing your wheels to the vehicle’s hub, enduring immense stress from acceleration, braking, and cornering forces. A failure in one of these seemingly simple parts can lead to catastrophic consequences, including wheel detachment and loss of vehicle control. Therefore, understanding the importance, types, and selection criteria for wheel bolts is crucial for every vehicle owner. This article will explore the world of wheel bolts, their various forms, and why choosing strong, reliable options is paramount for your safety.

Section 2 The Importance of Strong and Reliable Wheel Bolts

Wheel bolts are more than just simple fasteners; they are key safety components that ensure the wheels remain securely attached to the vehicle. The consequences of using substandard or damaged wheel bolts can be catastrophic:

2.1 Wheel Separation: A leading cause of accidents, wheel separation occurs when the bolts fail, resulting in loss of vehicle control.

2.2 Reduced Vehicle Handling: Loose wheel bolts can cause vibrations, uneven tire wear, and decreased handling responsiveness, making the vehicle difficult to control.

2.3 Premature Wear: Loose or improperly tightened bolts can cause increased stress on the wheel hub, leading to premature wear of the hub and other components.

2.4 Potential for Accidents: The combination of any of these factors significantly increases the risk of accidents, endangering the vehicle’s occupants and other road users.

Therefore, investing in strong, reliable wheel bolts is essential for the safety of any vehicle

Section 3 Understanding Wheel Fastener Terminology

Navigating the world of wheel fasteners can be confusing if you’re unfamiliar with the terminology. Here’s a breakdown of some key terms:

Table 1: Key Wheel Fastener Terms

| Term | Description |

| Wheel Bolt | A threaded fastener that screws into a threaded hole on the hub, used to directly secure the wheel. |

| Wheel Stud | A threaded rod permanently fixed to the hub. The wheel is secured with a lug nut that screws onto the stud. |

| Lug Nut | A nut used to secure the wheel to the hub when studs are present. |

| Hub | The central part of the wheel, to which the brake rotors and other wheel assembly components are attached. |

| Thread Pitch | The distance between adjacent threads on a bolt or stud, crucial for compatibility. |

| Torque | The rotational force applied when tightening a fastener, measured in foot-pounds or Newton-meters. |

| Wheel Fastener | A generic term referring to all components used to secure the wheel (bolts, studs, and lug nuts), also known as wheel hardware. |

| Rim | The outer edge of the wheel where the tire is mounted. |

Section 4 Types of Wheel Bolts and Fasteners

Wheel bolts are available in a variety of types, each designed for specific vehicles and wheels. Here are some of the most common types you might encounter:

4.1 Standard Wheel Bolts: The most common type, designed for OEM wheels and typically used in standard vehicle applications.

4.2 Extended Thread Wheel Bolts: These have longer threads to ensure secure attachment when aftermarket wheels with thicker mounting surfaces are used.

4.3 Locking Wheel Bolts (Wheel Security Bolts): These are designed to prevent wheel theft with a unique key pattern for removal.

4.4 Conical Seat Bolts: These have a cone-shaped seat that centers the wheel on the hub.

4.5 Ball Seat Bolts: Bolts with a rounded, ball-shaped seat, often found on European vehicles.

4.6 Flat Seat Bolts: Used with flat-surfaced wheel mounting areas.

4.7 Hub Bolts: These often refer to bolts securing the hub to the suspension, but can also refer to wheel bolts in some instances.

4.8 Tire Bolts: Another term for wheel bolts, emphasizing their role in attaching tires to the hub.

4.9 Wheel Retention Bolts: Bolts specifically designed to retain the wheel and prevent detachment.

4.10 Lug Bolts: Sometimes used interchangeably with wheel bolts; however, they are sometimes only present in the presence of studs.

4.11 Rim Bolts: Generally bolts that secure the rim to other parts of the wheel or hub.

4.12 Wheel Attaching Bolts: A general term that refers to any bolt attaching a wheel to a hub.

Section 5 The Significance of Strong and Reliable Wheel Bolts

Using subpar wheel bolts can significantly compromise the safety of your vehicle. Poor-quality bolts may suffer from:

5.1 Shearing: Bolts breaking under stress

5.2 Stripping: Thread damage causing the bolt to lose grip

5.3 Corrosion: Structural weakening caused by rust

5.4 Loosening: Bolts failing to maintain proper clamping force

These failures can lead to wheel detachment, resulting in loss of vehicle control and potentially severe accidents. Opting for strong, reliable wheel bolts ensures:

5.5 Improved Safety: Lower risk of wheel separation

5.6 Consistent Performance: Stable fastening, even under high stress

5.7 Durability: Resistance to wear, corrosion, and fatigue

5.8 Peace of Mind: Security of a safe wheel assembly

Section 6 Key Considerations When Selecting Wheel Bolts

6.1 Material: High-tensile steel alloys or hardened steel offer the best strength and durability.

The materials used to manufacture wheel bolts play a significant role in their strength, durability, and resistance to corrosion. Common materials include:

6.1.1 Carbon Steel: A cost-effective option, carbon steel bolts are often heat-treated and coated for increased strength and corrosion resistance.

6.1.2 Alloy Steel: Stronger and more durable than carbon steel, alloy steel bolts are preferred for high-performance vehicles or heavy loads.

6.1.3 Forged Steel: Known for its superior strength and durability, forged steel is often used in high-stress applications, such as motorsports and heavy-duty trucks.

6.1.4 Stainless Steel: Provides superior corrosion resistance, making it suitable for marine applications or areas with harsh weather conditions.

Selecting the appropriate material depends on the specific application needs, performance requirements, and environmental factors.

6.2 Size and Thread Pitch: Ensure the bolts match your vehicle’s specifications. Your vehicle manual or a professional can provide the correct sizing and thread pitch.

6.3 Seat Type: Select the appropriate seat type (conical, ball, or flat) that matches your wheels.

6.4 Length: The bolt should have adequate length to ensure proper thread engagement for secure fastening.

6.5 Material Grade: This defines the strength and mechanical properties of the bolt material.

6.6 Surface Finish: Coatings such as zinc plating, black oxide, or chrome are applied to improve corrosion resistance.

6.7 Diameter: Measured in millimeters (mm) or inches, this refers to the diameter of the bolt’s threaded shank.

6.8 Quality Standards: Opt for bolts manufactured to high industry standards and certifications.

6.9 Brand Reputation: Buy from known brands with a reputation for quality, engineering, and long-term performance.

Section 7 Key Considerations for Choosing Wheel Bolts

When selecting wheel bolts, several critical factors must be taken into account:

7.1 Vehicle Compatibility: Ensure the bolts match your vehicle’s make, model, and wheel specifications.

7.2 Load Rating: Select bolts rated for the load they will be subjected to, particularly for trucks and heavy-duty vehicles.

7.3 Material Strength: Choose materials that provide the necessary strength and durability for your vehicle’s operating conditions.

7.4 Corrosion Resistance: Select coated or corrosion-resistant bolts for areas with high moisture or salt exposure.

7.5 Standards: Choose bolts that meet all relevant industry standards.

Section 8 Where to Purchase High-Quality Wheel Bolts: Recommending Welleshaft

When it comes to sourcing reliable, high-quality wheel bolts, choose a supplier with an excellent reputation for engineering and excellence. We highly recommend Welleshaft as a trusted global supplier and contract manufacturer specializing in high-quality automotive fasteners.

Why Choose Welleshaft

8.1 Global Reputation: Welleshaft has a proven track record of supplying dependable parts to automotive manufacturers, distributors, and aftermarket specialists worldwide.

8.2 Exceptional Quality: They maintain meticulous quality control, adhering to stringent standards and utilizing only top-grade materials.

8.3 State-of-the-Art Manufacturing: Welleshaft uses advanced manufacturing technology to ensure that their products consistently meet and exceed industry standards.

8.4 Wide Range of Products: They offer a vast selection of wheel bolts and related fasteners, suitable for diverse vehicle makes and models.

8.5 Reliable Supply Chain: Welleshaft has streamlined supply chains that prioritize consistent, timely production and dependable delivery.

8.6 Customization: Welleshaft also provides comprehensive customization for specific wheel bolt needs.

Selecting Welleshaft ensures that you receive high-quality wheel bolts engineered for safety and long-lasting performance.

Section 9 Additional Related Terms and Topics

(Here is where I will incorporate further terms from the image)

Table 2: Additional Wheel Component & Fastener Related Terms

| Term | Description |

| Lug Nuts (for vehicles that use lug nuts) | The fasteners that go onto the studs to secure the wheel. |

| Locking Wheel Nuts (for vehicles that use lug nuts) | Lug nuts designed to help to deter wheel theft. |

| Tire-Mounting Bolts | Another term for wheel bolts, focusing on their use in tire assembly. |

| Rotational Fixings | Refers to all types of fasteners for rotating components, including wheel bolts and studs. |

| Wheel Threaded Connectors | A general term for wheel fasteners involving a threaded connection. |

| Retention Bolts (for Wheels) | General description of fasteners securing the wheel to the hub. |

| Wheel Screws | Often used to refer to smaller fasteners used in wheel assembly. |

| Studs, Nuts & Clamps | Other related components in the automotive fastener sector. |

| Wheel Stud Failures | Issues associated with studs and other components in wheel assembly. |

| Threaded Products | A broader term referring to parts utilizing threads for assembly and joining. |

| Wheel Fastener Guide | Reference guides providing information for correct usage and selection of wheel fasteners. |

| **Wheel Fasteners | Wheel Hardware** |

| Wheel Bolts vs Studs | A description of the differences and uses of wheel bolts and wheel studs. |

| What are the bolts on wheels called? | Common question about wheel fasteners. |

| Why wheel bolts vs studs? | Question that refers to the engineering and manufacturing decisions regarding the use of different methods. |

| What is a bolt on wheel? | Informational question regarding the functionality and design of a wheel bolt. |

| Can you replace wheel bolts? | A common question about the need to replace wheel bolts. |

Section 10 The Role of Wheel Bolts in Wheel Safety

Wheel bolts directly contribute to vehicle safety by:

10.1Securing the Wheels: They provide the secure clamping force necessary to keep the wheels attached to the vehicle.

10.2 Preventing Wheel Separation: By maintaining a secure connection, they prevent the dangerous and often catastrophic event of wheel separation.

10.3 Maintaining Wheel Alignment: Proper torque on wheel bolts helps ensure the wheel is aligned and balanced properly for a smooth ride.

10.4 Ensuring Balanced Load Distribution: Even clamping force on all wheel bolts helps ensure that stress is distributed evenly over the wheel hub.

Section 11 Wheel Bolt Standards

Various standards and regulations govern the manufacturing and testing of wheel bolts to ensure safety and performance. Key standards bodies include:

11.1 ISO (International Organization for Standardization): ISO standards define dimensional and performance requirements for fasteners.

11.2 SAE International (Society of Automotive Engineers): SAE standards specify mechanical properties, materials, and testing requirements for fasteners in the automotive industry.

11.3 DIN (Deutsches Institut für Normung): DIN standards are widely used in Europe and specify the dimensions, materials, and testing requirements for wheel bolts.

Compliance with these standards ensures the quality and reliability of wheel bolts.

Conclusion

Strong, reliable wheel bolts are a cornerstone of vehicle safety and must be given due diligence for any vehicle owner, enthusiast, or technician. Understanding their importance, types, and proper maintenance practices is essential for ensuring safe travels. Choosing high-quality bolts from trusted suppliers, like Welleshaft, provides confidence and peace of mind knowing that your wheels are securely fastened. By prioritizing quality, correct installation, and regular maintenance, you can help ensure your own safety and that of others on the road.