Quick Cast Prototyping Solutions: Precision Metal Parts, Quickly

Section 1:Introduction

In today’s fast-paced product development environment, speed and efficiency are paramount. Traditional prototyping methods can often be time-consuming and costly, hindering innovation and delaying time-to-market. Quick cast prototyping offers a revolutionary solution, enabling rapid production of precision metal parts with unmatched speed and accuracy. This article will delve into the intricacies of quick cast prototyping, highlighting its advantages, applications, and how it can significantly accelerate your product development cycle.

Section 2:Understanding Quick Cast Prototyping

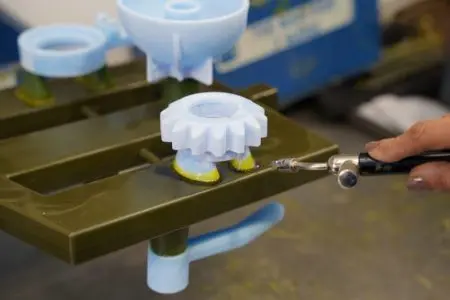

Quick cast prototyping, also known as rapid prototype casting, leverages advanced technologies to expedite the creation of metal prototypes. It involves a streamlined process that significantly reduces lead times compared to conventional methods. The core principle lies in the utilization of 3D printing technology to create intricate wax patterns directly from digital designs. These wax patterns are then used to produce molds for casting, resulting in high-fidelity metal prototypes that closely resemble the final product.

Section 3:Key Advantages of Quick Cast Prototyping

Accelerated Prototyping: Quick cast prototyping drastically reduces the time required to produce metal prototypes. This allows for rapid design iterations and faster decision-making, accelerating the overall product development cycle.

Enhanced Design Flexibility: The process offers exceptional design freedom, enabling the creation of complex geometries and intricate details that may be challenging or impossible to achieve with traditional methods.

Improved Accuracy and Precision: 3D printing technology ensures high accuracy and precision in the wax patterns, translating to highly accurate metal prototypes. This minimizes the risk of costly design flaws and rework.

Cost-Effectiveness: While initial tooling costs may be higher, quick cast prototyping can ultimately reduce overall development costs by minimizing the need for costly redesigns and iterations.

Reduced Time-to-Market: By accelerating the prototyping phase, quick cast prototyping enables businesses to bring products to market faster, gaining a competitive edge.

Section 4:Applications of Quick Cast Prototyping

Quick cast prototyping finds applications across a wide range of industries, including:

Aerospace: Prototyping of complex engine components, aircraft parts, and aerospace hardware.

Automotive: Rapid development of engine blocks, transmission components, and other critical automotive parts.

Medical Devices: Prototyping of surgical instruments, implants, and other medical devices requiring high precision.

Consumer Electronics: Prototyping of intricate electronic components, enclosures, and housings.

Industrial Machinery: Prototyping of complex gears, shafts, and other industrial components.

Section 5:Choosing the Right Quick Cast Prototyping Partner

Selecting the right partner for your quick cast prototyping needs is crucial for ensuring successful project outcomes. Consider the following factors when evaluating potential partners:

Expertise and Experience: Look for a partner with extensive experience in quick cast prototyping and a proven track record of success.

Technological Capabilities: Ensure that the partner possesses the latest technologies and equipment to deliver high-quality prototypes.

Quality Control Measures: Inquire about the partner’s quality control processes and certifications to ensure that prototypes meet stringent standards.

Communication and Collaboration: Choose a partner who fosters open communication and collaboration throughout the prototyping process.

Section 6:Welleshaft: A Trusted Global Supplier and Contract Manufacturer

Welleshaft has established itself as a leading provider of quick cast prototyping solutions, offering a comprehensive range of services to meet the diverse needs of its clients. With a strong emphasis on quality, innovation, and customer satisfaction, Welleshaft has earned a reputation as a trusted partner for businesses worldwide.

Key Features of Welleshaft’s Quick Cast Prototyping Services:

- Advanced Technology: Welleshaft utilizes state-of-the-art 3D printing and casting technologies to deliver high-precision prototypes.

- Experienced Team: A team of skilled engineers and technicians ensures that each project is executed with precision and efficiency.

- Quality Assurance: Welleshaft adheres to strict quality control measures to guarantee that prototypes meet the highest standards.

- Customer-Centric Approach: Welleshaft prioritizes customer satisfaction and provides personalized solutions to meet specific project requirements.

By partnering with Welleshaft, businesses can leverage the power of quick cast prototyping to accelerate product development, reduce costs, and gain a competitive advantage in the market.

Conclusion

Quick cast prototyping is revolutionizing the way products are developed, offering a faster, more efficient, and cost-effective approach to prototype production. By embracing this innovative technology, businesses can unlock new levels of design freedom, accelerate time-to-market, and gain a competitive edge in today’s dynamic market.