1.Aerospace Investment Castings | High-Precision Aerospace Component Casting by Welleshaft

Welleshaft stands out among aerospace casting companies, offering dependable aerospace castings built for both commercial and defense aviation programs. With close to 40 years of hands-on experience, we handle investment casting for aerospace components using a wide set of high-temperature alloy castings for aerospace engines, like stainless steel, nickel, aluminum, and cobalt-based materials.

2.Why Choose Welleshaft for Aerospace Investment Castings

Welleshaft ranks among the top 10 aerospace casting companies worldwide, known for delivering reliable precision castings for aerospace defense systems, satellites, and jet engine setups. As an ISO-certified aerospace casting company, we focus on tight tolerances, consistent quality, and design clarity, working with clients who search for aerospace precision casting near me and abroad.

(1)Our Strengths

Experienced team that supports from blueprint to final shape

In-house toolmaking and full CNC support

We keep control over every step of production

Able to handle bulk aerospace structural component casting services

Proven track record with complex geometries

Long-time supplier for OEM aerospace casting partners in civil and military industries

3.Key Aerospace Casting Capabilities

We provide full-stack casting-based assembly solutions for:

| Capacidade | Description |

| Design Support | Design review and prototype assistance from concept |

| Tooling | Custom toolmaking done in-house |

| Production | Low to large-scale midwest aerospace casting runs |

| Machining | CNC support after cast shaping |

| Testing | NDT and NADCAP-certified checks included |

| Delivery | Ships on time, both domestic and international |

Need airfoil castings for jet engines or aerospace castings for satellite structures? Our crew helps make sure each part lasts, works, and fits.

We solve complex casting challenges using high-temperature alloy castings for aerospace engines and other essential metals. As one of the top American aerospace technical castings providers, we make sure your specs get met—start to finish.

4.Common Aerospace Casting Applications

Our aerospace casting work fits a broad set of mission-critical and flight-ready parts for defense, commercial, and orbital gear.

(1)Flight Systems and Core Structures

Aerospace castings for turbine blades built for propulsion and power units

Lightweight aerospace castings for aircraft frames boost fuel economy

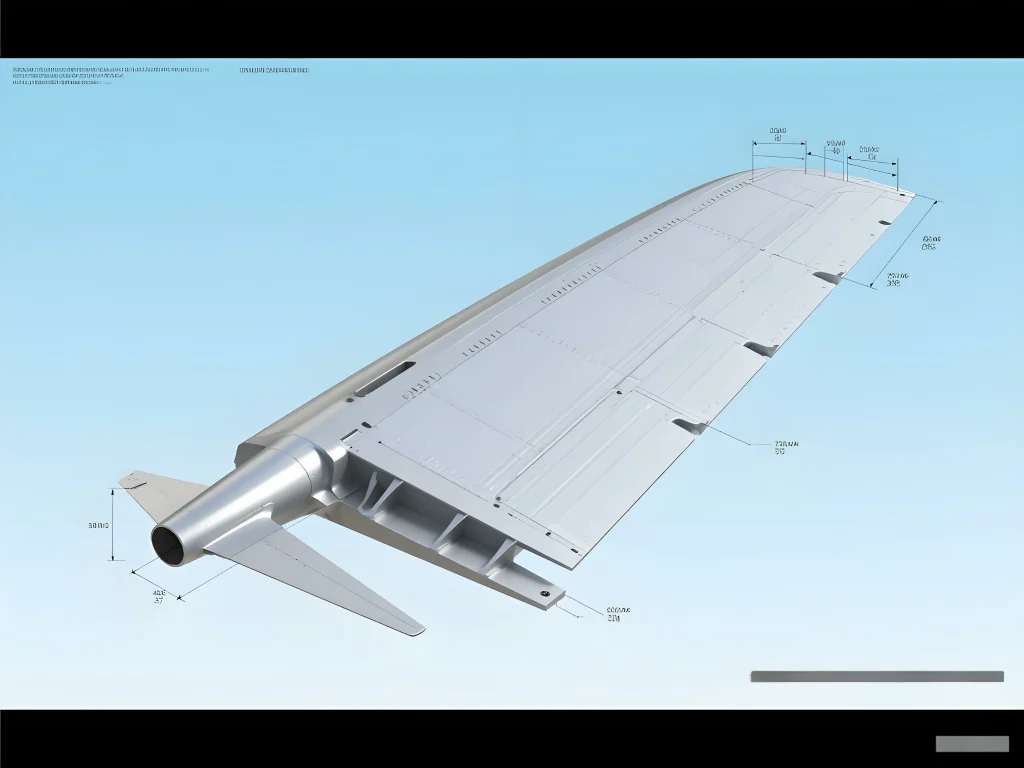

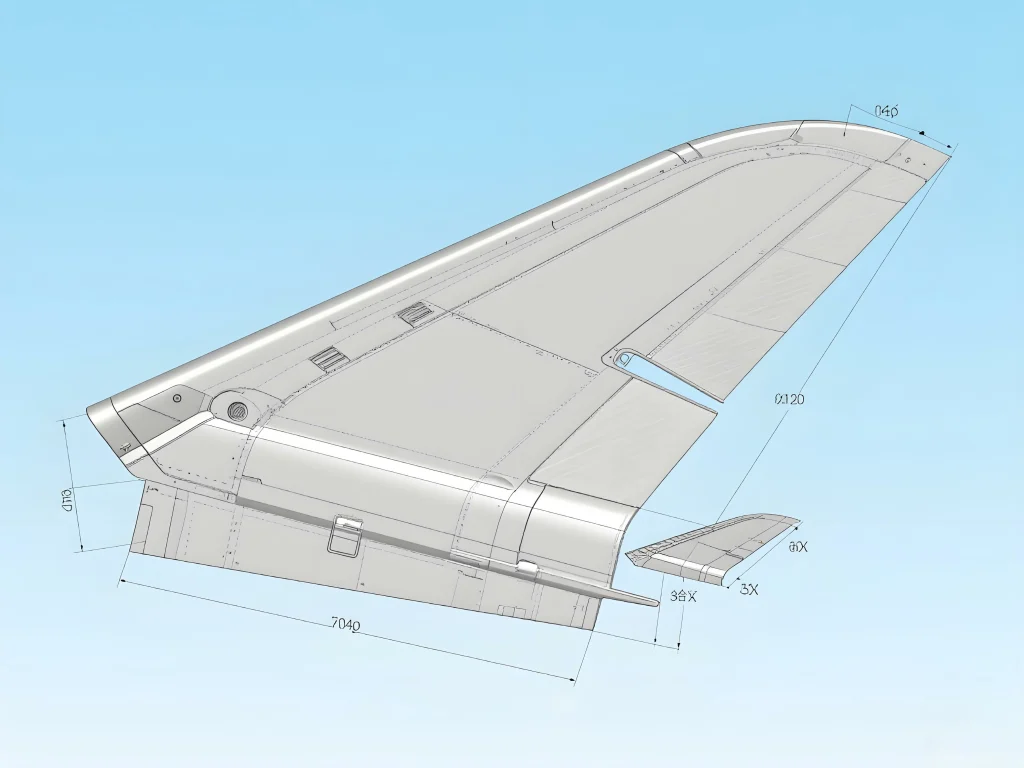

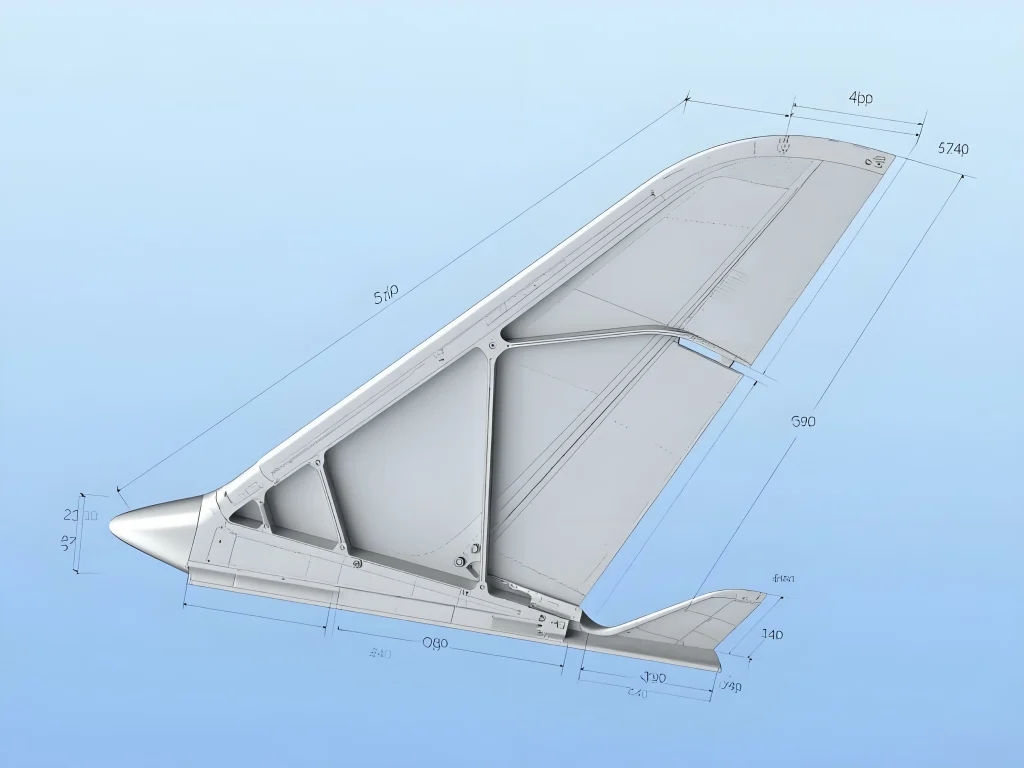

Strong and stiff aerospace structural component casting services for wings or body frames

Parts for brake systems, hydraulics, and flow systems

Gear for landing systems, cargo support, and motion assemblies

(2)Safety and Sensor Modules

Inner and outer sensor covers cast using A356 aluminum alloy

Control, motion, and response part housings

Bearing retainers and other precision castings for aerospace defense systems

(3)Military and Space-Use Parts

Aerospace castings for military aircraft made using defense-level alloys

Spacecraft component castings for aerospace systems and launch support

Airfoil castings for rocket propulsion to meet high-heat and force demands

Custom pieces used in aerospace casting for satellite structures

5.Materials Used in Aerospace Castings

Welleshaft uses a wide mix of aerospace-grade materials that suit flight loads, heat conditions, and electronic uses:

| Material | Application Examples |

| A356 Aluminum Alloy | Light frames, sensor modules |

| Nickel-Based Alloys (Ni) | Heat-resistant aerospace castings for turbine blades |

| Stainless Steel | Frame parts where rust-resist matters |

| Cobalt-Based Alloys | High-stress engine parts |

| Beryllium Copper | Electronic or circuit housing use |

These alloys help shape airfoil castings, support-heavy parts, and weight-saving structures for hard-use jobs. Whether building aerospace castings for military aircraft or passenger airframes, we pick the right alloy—no guesswork.

6.Certified Testing and Quality Assurance

All castings are checked closely—start to finish. Our inspection steps cover:

NDT checks by NADCAP rules

X-ray, ultrasound, and dye lookover

Certification records and trace reports

Fit tests and shape accuracy trials

Matches AS9100, ISO, and top-tier OEM specs

Thanks to our own testing team at American aerospace technical castings, we ship investment casting for aerospace components that meet high bars. If you’re an OEM aerospace casting partner or a defense buyer, you get quality parts, every time.

7.Precision Casting Case Studies

Case Study 1: Jet Engine Airfoil Castings

Problem: Needed to make complex airfoil castings for jet engines that hold up in heat and force.

Fix: Used nickel alloy and investment casting with cooling pathways.

Result: 25% lighter parts; boosted fuel burn by military aircraft.

Case Study 2: Military Aircraft Components

Problem: Needed strong cast parts for hydraulic systems.

Fix: Made stainless steel parts with exacting shape rules.

Result: No defects across 5 batch runs; picked by several aerospace casting companies.

8.People Also Ask

1.What is aerospace investment casting?

Aerospace investment casting makes detailed aerospace castings for flying systems using wax forms and molten metal fills.

2.Why use investment casting for aerospace parts?

It keeps tight size rules, gives clean surfaces, and shapes parts close to final form—great for airfoil castings, sensors, and aerospace structural component casting services.

3.What alloys work best in aerospace castings?

Nickel alloys, A356 aluminum, stainless, cobalt sets, and beryllium copper are used often in high-temperature alloy castings for aerospace engines.

4.Who are top aerospace casting companies?

Teams like Welleshaft, listed in the top 10 aerospace casting companies worldwide, serve OEM aerospace casting partners and defense groups.

5.What are the perks of aerospace airfoil castings?

Aerospace airfoil castings trim drag, guide airflow, resist heat, and stay strong in high skies.

9.Contact Welleshaft

Welleshaft is your reliable source for aerospace investment casting, whether it’s early models or repeat builds. From airfoil castings for rocket propulsion to serving OEM aerospace casting partners, we’re set to handle high-stakes jobs with care.Let’s build your aerospace castings—solid, accurate, and ready to fly.