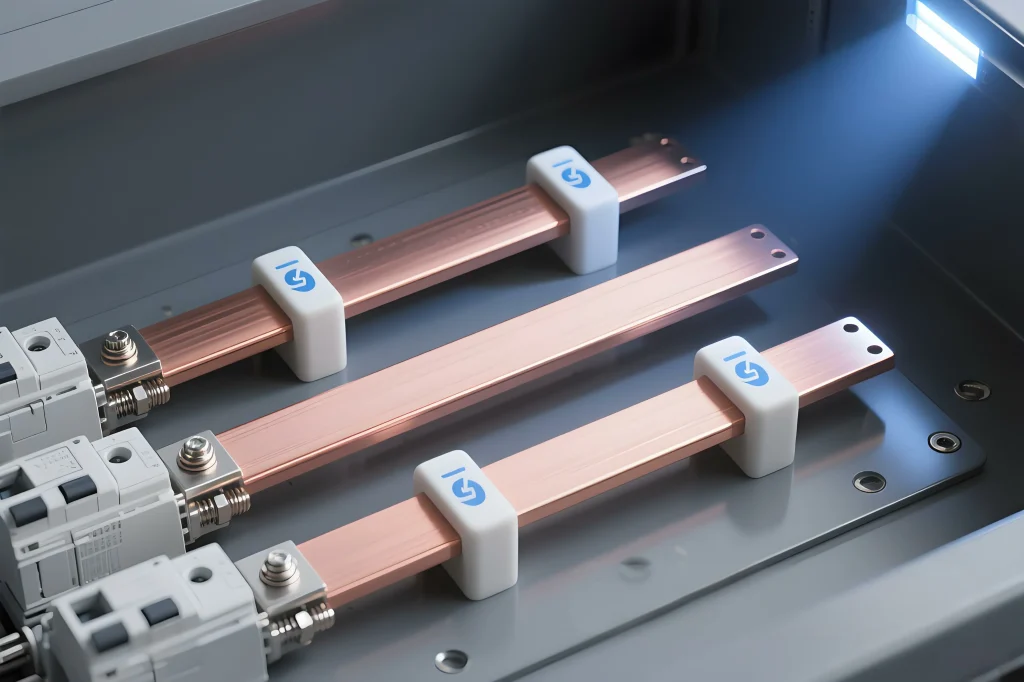

1.Introduction: What Are Plated Copper Bus Bars?

Plated copper bus bars are solid conductors coated with metals like tin or silver to improve corrosion resistance, conductivity, and durability. These bus bars serve as central nodes for distributing power in systems ranging from EV batteries to electrical switchgear. At Welleshaft, we specialize in Tin Plated Copper Bus Bars for EV Charging Systems, offering advanced tin plating and silver electroplating services that meet industrial and military specifications.

2.Principle of Tin and Silver Electroplating on Copper

The electroplating process involves immersing a cleaned copper bar into a plating bath where tin or silver ions bond to the surface through an electric current. This process ensures uniform coating, improved oxidation resistance, and extended lifespan. Welleshaft uses automated lines to maintain high consistency in Tin Plated Copper Bus Bars for EV Charging Systems, delivering mil-t-10727 compliant tin plating and ASTM B700 silver finishes that meet strict industrial standards.

3.Why Is Copper Bus Bar Tin Plated?

Copper bus bars are tin plated to enhance corrosion resistance, maintain conductivity, and extend service life in harsh environments. This thin protective layer prevents oxidation without impacting electrical performance. At welleshaft, our tin plated copper bus bar solutions meet MIL-T-10727 standards, offering exceptional durability and solderability across industrial applications.

4.What Is MIL-T-10727 Tin Plating Specification?

MIL-T-10727 is a U.S. military specification defining quality standards for tin plating copper components. It mandates coating thickness, adhesion, and purity levels to ensure reliability in electrical systems. Welleshaft follows this spec for all tin plated copper bars, making our products ideal for mission-critical use in energy, EV, and telecom sectors.

5.Difference Between Tin Plated and Silver Plated Copper Bus Bars

While tin plated bus bars resist corrosion and are cost-effective, silver plated copper bus bars offer superior conductivity and thermal performance. Silver is ideal for high-current systems and RF applications. Welleshaft provides both finishes, letting customers select the best solution for their environment and budget.

6.How to Choose Between Silver Plating and Tin Plating for Busbars

The choice between silver plating copper and tin plating depends on your application. Use bright tin plating for cost-effective corrosion resistance. Opt for silver plating (ASTM B700 compliant) when conductivity, temperature tolerance, and reliability under high loads are critical.

7.Tin Plated vs Bare Copper for Electrical Conductivity

Bare copper oxidizes quickly, reducing long-term efficiency. Tinned copper bus bars preserve surface conductivity over time, especially in humid or industrial environments. Our plated copper solutions ensure consistent performance without ongoing maintenance.

8.What Are the Benefits of Matte Tin Plating vs Bright Tin Plating?

Matte tin plating offers improved solderability and less whisker growth, making it ideal for sensitive electronics. Bright tin plating provides a shiny finish and is used for exposed components in switchgear. Welleshaft offers both options for plated copper bus bars and tin plated aluminum bus bars.

9.Tin Plating Thickness Standards for Bus Bars

| Standard | Coating Type | Thickness Range |

| MIL-T-10727 | Electroplated Tin | 0.0003″–0.0005″ |

| ASTM B545 | Matte/Bright Tin | 5–12 microns |

| ASTM B700 | Silver on Copper | 40–60 microinches |

These ensure durability, conductivity, and solderability. Welleshaft precisely controls coating thickness to meet customer specs.

10.Applications for Tin Plated Aluminum and Copper Bus Bars

Tin plated aluminum bus bars are ideal for lightweight, high-current assemblies in switchgear and renewable energy systems. Our tin copper bus bars and tinned copper flat bars are used in EV battery packs, industrial panels, and power grids.

11.Silver Plated Copper for PCB Grounding and RF

Silver plated copper bars are critical in high-frequency, low-resistance applications like PCB grounding and RF systems. Their low impedance makes them the go-to choice for telecom and aerospace. Welleshaft offers electroplating silver onto copper for optimized performance.

12.Welleshaft’s Plating Services & Technical Capabilities

Welleshaft provides tin plating and silver plating services backed by international standards. We offer:

In-house automated bar plating lines

MIL-T-10727 and ASTM B700 compliance

XRF coating thickness analysis

RoHS-compliant finishes

Custom OEM and small-batch runs

13.Certifications and Equipment

Welleshaft is ISO 9001 and ISO 14001 certified. Our facility includes:

Precision electroplating tanks with temperature and flow controls

High-purity plating baths

Optical and XRF inspection tools

Environmental fume extraction systems

We ensure every tin plated copper bar and silver plated busbar meets or exceeds industry expectations.

14.Our Team and Expertise

Our engineers bring over 15 years of collective experience in electroplating and busbar manufacturing. We’ve supported over 500 global clients across power generation, automotive, energy storage, and telecom sectors.

15.Case Study: EV Manufacturer Upgrades to Silver Plated Copper Busbars

A leading EV company approached Welleshaft to reduce energy losses in their battery interconnects. We provided custom silver plated copper busbars compliant with ASTM B700. The result: a 17% reduction in heat buildup and a 9% boost in energy efficiency.

16.Common Questions About Plated Copper Bars

(1)Why is copper bus bar tin plated?

To resist corrosion and oxidation without losing conductivity.

(2)Is silver plating better than tin plating on copper?

Yes, if you prioritize conductivity and performance over cost.

(3)What is ASTM B700 and is it RoHS compliant?

ASTM B700 defines silver plating standards. Yes, we offer RoHS-compliant silver plating.

(4)How long does tin plating last?

Typically 10–20 years, depending on environment and thickness.

(5)Can aluminum bus bars be tin plated effectively?

Yes, using specific preparation processes.

17.Why Choose Welleshaft?

Over 10 years of metal finishing experience

MIL and ASTM certified plating processes

Short lead times, fast prototyping

Global logistics and multilingual support

Dedicated plating lines for tin plated and silver plated copper busbars

18.Common Questions About Tin and Silver Plated Copper Bars

(1)What causes discoloration in tin plated copper bus bars?

Exposure to high humidity or industrial gases can discolor tin. Our matte tin plating reduces this risk.

(2)Is silver plating better than tin plating on copper?

Yes, for conductivity and temperature tolerance. Tin is better for cost-sensitive, non-critical systems.

(3)How to test tin thickness on copper bars?

Non-destructive XRF (X-ray fluorescence) is commonly used. Welleshaft includes coating reports with every order.

(4)Can aluminum bus bars be tin plated effectively?

Yes. Tin plated aluminum bus bars offer bonding and corrosion resistance in hybrid systems.

Welleshaft, specializing in copper bar plating, silver plating to ASTM B700, and mil-t-10727 tin plating services. With over a decade of hands-on experience, our expert supports clients across the energy, automotive, and telecom sectors.