1.Why Aluminum Heat Sink QC Matters

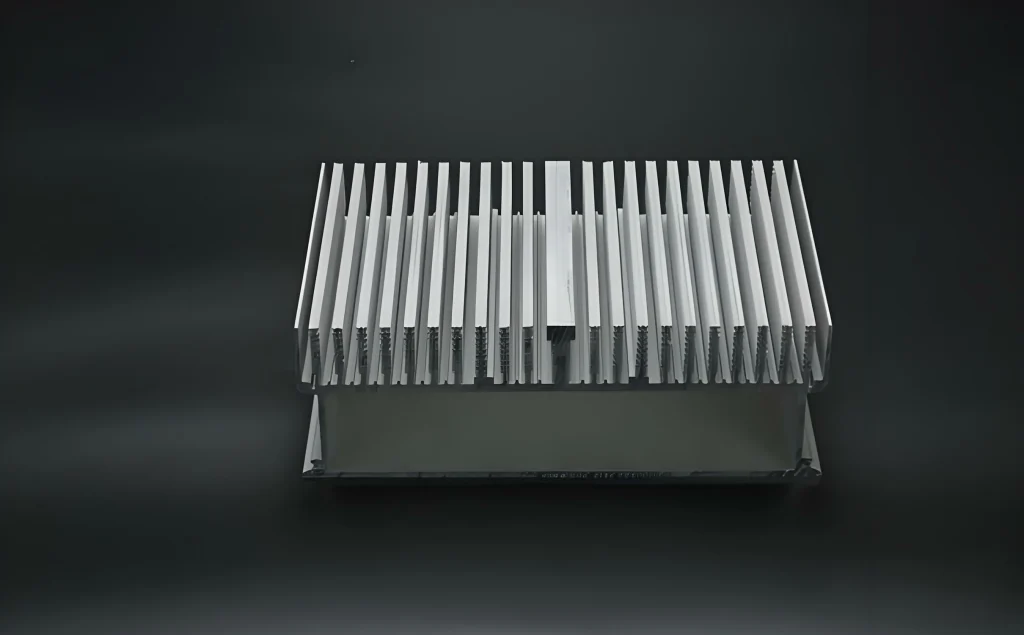

In modern electronics manufacturing, aluminum heat sink inspection is a critical step to ensure optimal thermal performance, reliability, and compliance with industry standards. A single poorly performing heat sink can compromise the efficiency of CPUs, GPUs, power supplies, and other high-performance electronics. Choosing the Right Aluminum Heat Sink QC Service enables manufacturers to detect defects such as warping, poor surface finish, dimensional inaccuracies, and thermal conductivity issues early, saving time, reducing costs, and ensuring consistent product quality.

Choosing the right aluminum heatsink QC service can be challenging due to differences in inspection accuracy, turnaround time, and cost. This guide explores the process in depth and provides practical advice for selecting a provider that meets your production requirements.

2.Understanding Aluminum Heat Sink QC Services

1.Aluminum heat sink testing service involves multiple steps to verify both the physical and functional performance of the component. Core inspection procedures typically include:

2.Dimensional inspection: Verifying tolerances using calipers, CMM, or laser scanners.

3.Surface quality assessment: Detecting scratches, burrs, or anodization issues.

4.Thermal performance testing: Measuring heat dissipation efficiency.

5.Material verification: Ensuring alloy composition meets specifications.

By hiring a professional heat sink QC service for manufacturers, you gain access to trained engineers, standardized inspection procedures, and reliable documentation that supports compliance and export requirements.

3.Key Challenges in Choosing a QC Provider

Selecting the right QC service is not straightforward. Manufacturers face several common difficulties, making Choosing the Right Aluminum Heat Sink QC Service essential to ensure accurate defect detection, reliable performance, and compliance with industry standards.

1.Accuracy: How precise are the measurements? Do they have the right tools for aluminum heatsink QC service?

2.Cost: Comparing the cost of aluminum heatsink QC service across providers while ensuring quality is difficult.

3.Speed: Fast inspection services may compromise accuracy, while slower services may delay production.

Other factors include certifications, experience with specific electronics applications, and the ability to offer on-site QC service for aluminum heat sinks.

4.Steps to Choose the Right Aluminum Heat Sink QC Service

(1)Evaluate Technical Capabilities

When looking for a reliable aluminum heat sink inspection and QC service, check for:

1.Precision measuring tools (CMM, laser profilometers)

2.Thermal testing rigs for functional evaluation

3.Experience with industrial electronics

4.Ability to handle custom QC service for high-performance heat sinks

Ask providers “How do professionals ensure accurate heat sink inspection?” and request sample reports to evaluate thoroughness.

(2)Assess Standards and Certification

Top-quality services follow industry standards such as ISO 9001, IPC, or JEDEC thermal guidelines. Confirm whether the provider offers:

1.Aluminum heat sink inspection and certification service

2.Traceable measurement protocols

3.Standardized reporting procedures

Understanding what standards do heat sink QC services follow helps prevent production errors and thermal failures.

(3)Compare Cost vs. Benefit

While price is important, low-cost providers may compromise precision. Consider:

1.Cost of aluminum heatsink QC service relative to potential losses from defective products

2.Value-added services, including consultation and customized inspection solutions

3.Availability of industrial heat sink QC solutions for electronics

Ask yourself: “How much does aluminum heat sink QC service cost, and is it worth the reliability it offers?”

(4)Consider On-Site or Remote Inspection Options

Depending on your production needs, on-site QC service for aluminum heat sinks can be more efficient. Advantages include:

1.Immediate feedback for manufacturing adjustments

2.Reduced transportation risks

3.Faster turnaround for high-volume production

Some providers also offer remote reporting or temporary lab setups for larger orders.

(5)Review Client Experience and Case Studies

The best providers demonstrate experience with:

1.Automotive electronics

2.Power supply units

3.High-performance computing components

Check references and case studies to evaluate reliability. Professional heat sink QC service for manufacturers should provide clear documentation, images, and reports demonstrating defect detection and corrective actions.

5.Common Questions When Hiring a Heat Sink QC Provider

1: How often should aluminum heat sinks undergo QC inspection?

Regular inspections are recommended for every production batch or at critical process stages to prevent thermal failures.

2: Can QC services prevent heat sink thermal failures?

Yes, through functional and material testing, QC services detect flaws that could compromise heat dissipation.

3: Which QC method is best for aluminum heat sinks?

A combination of dimensional, visual, and thermal testing ensures comprehensive evaluation.

4: What should I look for in a heat sink quality control provider?

Certifications, experience, technical equipment, accurate reporting, and on-site support.

5: What questions should I ask before hiring a heat sink QC provider?

Ask about turnaround times, inspection scope, report formats, certifications, and past case studies.

6.Why Hire a Professional Aluminum Heatsink QC Service

1.Reliability: Reduces product failures and warranty claims.

2.Compliance: Ensures components meet ISO, JEDEC, and client specifications.

3.Cost-efficiency: Prevents scrap and rework.

4.Flexibility: Offers custom QC service for high-performance heat sinks and scalable inspection solutions.

7.Comparison Table: Selecting the Best QC Provider

| Factor | What to Consider | Questions to Ask |

| Accuracy | Tools, methods, repeatability | Can they detect hidden defects? |

| Speed | Turnaround time, batch size handling | Do they offer same-day reporting? |

| Cost | Per unit, per batch, subscription | How much does aluminum heat sink QC service cost? |

| Certifications | ISO, IPC, JEDEC | Which standards do they follow? |

| Experience | Industry, product type | Have they handled similar high-performance heat sinks? |

Written by the engineering team at welleshaft , experts in electronics manufacturing QC. With over a decade of experience in heat sink testing, certification, and quality assurance, our team helps manufacturers ensure thermal efficiency, reliability, and compliance worldwide.