1.Bevel Gear Troubleshooting & Repair Services | Welleshaft

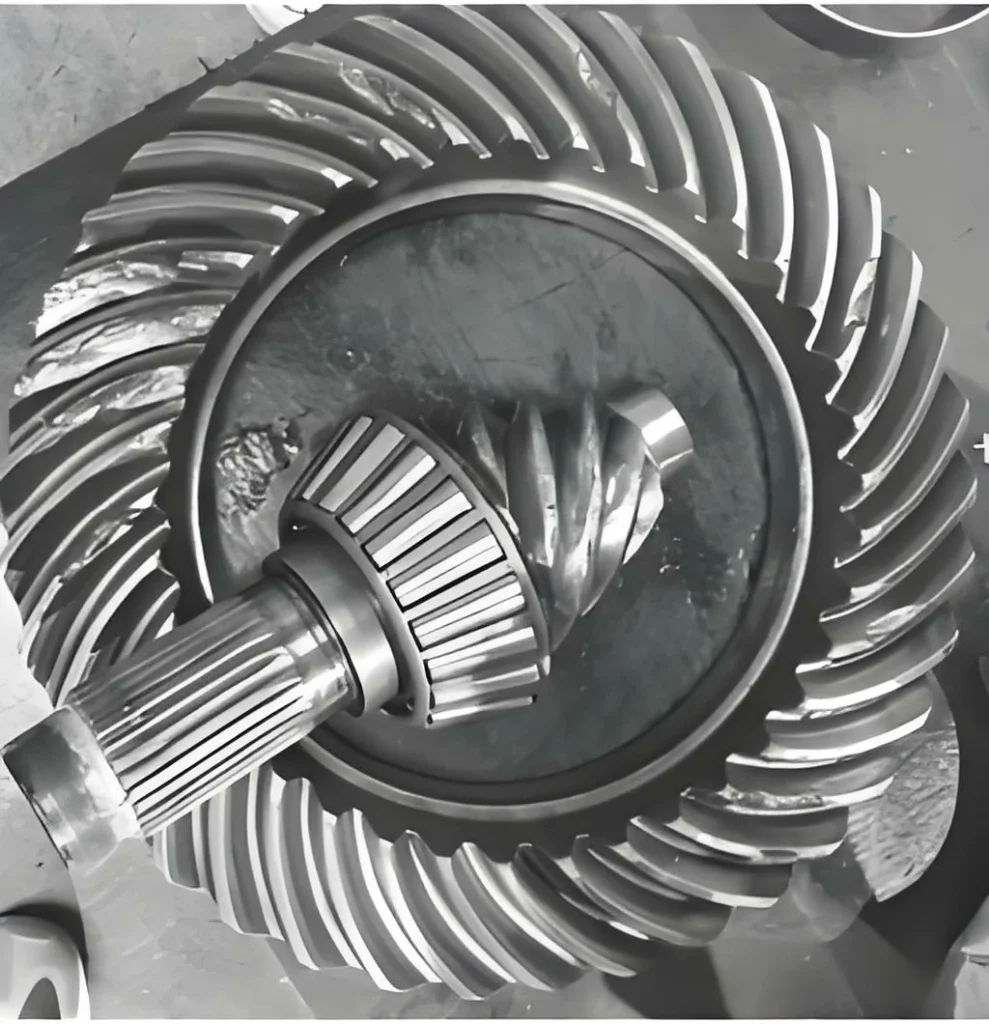

Bevel gears are a critical component in many industrial machines, transmitting torque and changing the axis of rotation efficiently. However, unexpected failures in bevel gears can lead to costly machine downtime, unplanned maintenance, and production losses. Industrial facilities that rely on precise bevel gears for bevel gears manufacturing, precision bevel gear production, or spiral bevel gear manufacturing need expert Bevel Gear Troubleshooting services, including industrial bevel gear inspection, bevel gear machining services, and custom bevel gear repair services for heavy machinery. At Welleshaft, we provide comprehensive Bevel Gear Troubleshooting and repair services, ensuring your machinery runs reliably with minimal disruptions.

2.Understanding the Impact of Bevel Gear Failures

(1)Unexpected Machine Downtime Due to Bevel Gear Failure

Bevel gear failures can halt production immediately, leading to significant financial losses. Common causes include:

- Tooth breakage or pitting, which disrupts torque transmission.

- Misalignment between bevel gear and pinion, causing uneven load distribution.

- Overheating due to insufficient lubrication or excessive load, reducing gear life.

Even a single failed bevel gear in a critical assembly, such as zerol bevel gear or straight bevel gears, can stop an entire production line. This is especially costly in heavy industries relying on CNC bevel gear production or custom bevel gear manufacturing.

Solution: Regular bevel gear inspection services and early diagnosis using precision bevel gear inspection and maintenance solutions can prevent catastrophic failures. Welleshaft engineers perform bevel gear wear inspection and corrective services to detect issues before they escalate.

(2)Difficulty in Early Detection of Misalignment or Gear Wear

Bevel gears, including spiral miter gears and straight bevel gear assemblies, often operate in enclosed housings, making visual inspection challenging. Signs of wear, misalignment, or fatigue can be subtle, such as:

- Slight vibration or unusual noise in the bevel gear and pinion

- Gradual reduction in performance or torque transmission efficiency.

- Minor surface pitting that is not immediately noticeable.

Without proper monitoring, these early warning signs can be overlooked, leading to sudden breakdowns. For example, large bevel gear repair and restoration specialists are often called in after small issues escalate into major failures.

Solution: Implementing a structured inspection workflow with on-site bevel gear maintenance for industrial equipment or laboratory-grade bevel gear quality inspection and defect rectification ensures early detection. Welleshaft’s bevel gear reverse engineering and reconditioning services allow precise identification of wear patterns and misalignment before production is impacted.

(3)High Cost of Unplanned Maintenance and Production Losses

Unplanned maintenance due to bevel gear failure carries several hidden costs:

- Replacement costs for custom or high-precision bevel gears.

- Downtime losses, especially in continuous manufacturing operations.

- Labor and emergency repair expenses, often higher than scheduled maintenance.

For companies relying on industrial bevel gear inspection and precision bevel gear production, these costs can quickly escalate. Additionally, improper or rushed repairs may cause bevel gear noise, vibration, or premature failure.

Solution: Welleshaft provides professional bevel gear alignment and refurbishment and bevel gear noise reduction and performance tuning services, minimizing downtime and extending gear life. Our emergency bevel gear repair for manufacturing plants ensures rapid response in critical situations, preventing cascading production losses.

3.Bevel Gear Troubleshooting Process: Step by Step

- Initial Assessment

Visual inspection of spiral gear, zerol bevel gear, or straight bevel gears.

Identifying wear patterns, chipping, pitting, or misalignment.

- Precision Measurement & Inspection

Using bevel gear testing, repair, and alignment company tools for backlash, tooth thickness, and pitch analysis.

Measuring gear alignment and concentricity for CNC bevel gear production or custom bevel gear manufacturing.

- Failure Analysis

Root cause determination using metallurgical testing or operational history review.

Identifying common failure modes such as overload, lubrication issues, or material defects.

- Repair & Maintenance

Reconditioning worn gears through bevel gear machining and repair service provider processes.

Aligning assemblies and adjusting backlash for precision bevel gear inspection and maintenance solutions.

- Preventive Recommendations

Scheduling regular industrial bevel gear inspection.

Implementing lubrication, load management, and operational best practices.

4.Common Questions About Bevel Gear Troubleshooting

- What are the most common bevel gear problems in machinery?Tooth wear, misalignment, pitting, overheating.

- How to fix noise and vibration in bevel gears?Alignment, lubrication, and precision machining.

- Can worn bevel gears be reconditioned instead of replaced?Yes, via bevel gear refurbishment and performance optimization.

- How often should industrial bevel gears be inspected?Recommended at regular intervals based on operating hours and load.

- What tools are used for bevel gear troubleshooting and inspection?Backlash gauges, micrometers, CMM, gear analyzers.

Welleshaft is a professional industrial gear inspection and repair provider with over 10 years of experience in bevel gear machining services, precision bevel gear inspection, and custom bevel gear manufacturing. Our engineers specialize in troubleshooting, reconditioning, and optimizing gears for heavy machinery, ensuring maximum uptime and operational efficiency.