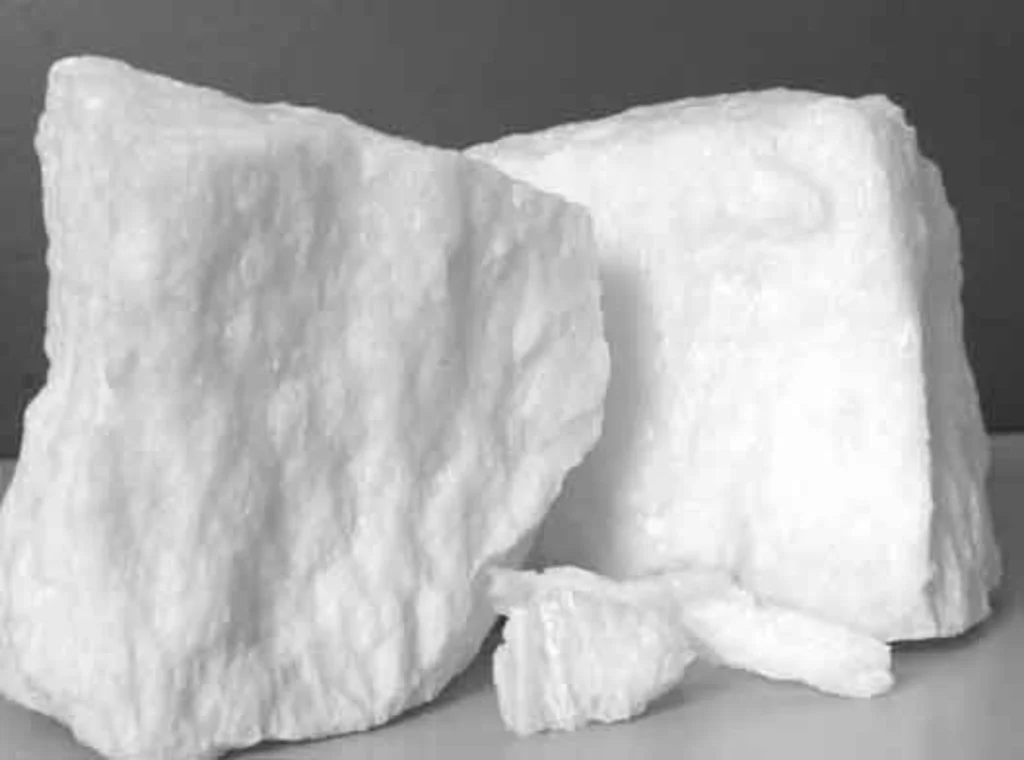

Medical Grade Aluminum Oxide: Bio-Compatibility & Implant Applications

Introduction

Medical-grade aluminum oxide, also known as alumina (Al₂O₃), is a high-purity ceramic material prized for its exceptional bio-compatibility, wear resistance, and chemical inertness. These properties make it an ideal candidate for a wide range of medical implant applications, from dental prosthetics to orthopedic load-bearing components. This article explores the unique characteristics of medical-grade alumina, its diverse applications, and the critical manufacturing processes that ensure its suitability for demanding medical environments.

What is Medical Grade Aluminum Oxide?

Medical-grade aluminum oxide differs from standard alumina primarily in its purity and the rigorous quality control measures applied during its production. It is typically manufactured to a minimum purity level (often exceeding 99.9%), minimizing the presence of potentially harmful impurities that could trigger adverse biological reactions.

Table 1: Key Properties of Medical Grade Aluminum Oxide

| Property | Value | Importance for Implants |

| Purity | >99.9% | Minimizes inflammatory responses and promotes bio-compatibility. |

| Density | ~3.95 g/cm³ | Contributes to strength and load-bearing capacity. |

| Hardness (Vickers) | ~1500 HV | Provides excellent wear resistance, crucial for long-term implant performance. |

| Young’s Modulus | ~380 GPa | Offers stiffness and resistance to deformation under load. |

| Fracture Toughness | ~4 MPa·m^(1/2) | Provides resistance to cracking and catastrophic failure. |

| Bio-Compatibility | Excellent | Ensures that the material does not elicit a toxic or immunogenic response from the body. |

| Chemical Inertness | Excellent | Resists degradation and corrosion in the harsh biological environment. |

Bio-Compatibility: The Cornerstone of Medical Applications

Bio-compatibility refers to the ability of a material to interact with a living biological system without eliciting an adverse response. Medical-grade alumina exhibits exceptional bio-compatibility due to its chemical inertness and high purity. This minimizes the risk of:

Inflammation: Reduced inflammatory response around the implant site.

Toxicity: Absence of toxic elements that could leach into the surrounding tissues.

Allergic Reactions: Minimization of allergic reactions due to the material’s inert nature.

Foreign Body Response: Reduced encapsulation of the implant by fibrous tissue.

Key Applications of Medical Grade Aluminum Oxide

Medical-grade alumina finds applications in a wide range of medical implants and devices, including:

Dental Implants: Alumina is used in dental implant abutments and implant bodies, providing excellent strength, aesthetics, and bio-compatibility.

Orthopedic Implants: Alumina is a common component of hip and knee replacements, offering superior wear resistance and long-term durability. It’s often used as a bearing surface in these joint replacements.

Spinal Implants: Alumina is used in spinal fusion devices and interbody cages, promoting bone growth and stability.

Surgical Instruments: Certain surgical instruments benefit from the hardness and wear resistance of alumina, allowing for sharper edges and longer lifespan.

Bone Scaffolds: Alumina-based scaffolds are being explored for bone regeneration applications, providing a framework for new bone growth.

Hearing Implants: Cochlear implants and other hearing devices utilize alumina due to its bio-compatibility and electrical insulation properties.

Manufacturing Processes: Ensuring Quality and Performance

The manufacturing process for medical-grade alumina components is critical to ensuring their quality, reliability, and performance. This involves several key stages:

Parts Processing

Material Selection: Choosing the highest purity alumina powders with controlled particle size distribution is crucial.

Powder Preparation: Pre-processing of the powders to ensure uniform mixing and removal of agglomerates.

Processing Technology

Sintering

Description: Sintering is a heat treatment process that consolidates the powder compact into a dense, solid component.

Processing Technology: Medical-grade alumina is typically sintered at high temperatures (1500-1700°C) in controlled atmospheres to achieve optimal density and mechanical properties.

Dimensional Tolerance: Sintering can introduce shrinkage, requiring precise control of the sintering process and subsequent machining to achieve desired dimensions.

Processing Capacity: The size and complexity of components that can be sintered are limited by furnace size and sintering uniformity.

Dimensional Tolerance: Sintering can introduce shrinkage, requiring precise control of the sintering process and subsequent machining to achieve desired dimensions.

Molding

Description: Shaping the alumina powder into a green body before sintering

Processing Technology: Techniques like die pressing, isostatic pressing, or injection molding are used to form the initial shape.

Processing capacity: depends on the molding process. Die pressing allows for high-volume production of simple shapes. Injection molding can create more complex geometries but requires more tooling costs.

Processing Accuracy: This is controlled by die/mold precision and powder consistency.

Scope of application: Medical-grade alumina components need to be compatible with the sterilization methods used in medical environments.

Grinding Processing

Description: Achieving final dimensions and surface finish.

Processing Technology: Precision grinding with diamond tools is employed to achieve the required surface finish and dimensional accuracy.

Processing Accuracy: Grinding can achieve tolerances down to a few microns, ensuring precise fit and function.

Dimensional Tolerance: Tight tolerances are essential for ensuring proper fit and function within the implant assembly.

Scope of Application: Grinding is used for complex shapes and fine details.

Type: CNC Grinding, Surface Grinding, Cylindrical Grinding.

Processing Parameters and Accuracy Requirements

The table below summarizes key processing parameters and accuracy requirements for medical-grade alumina components:

| Parameter | Requirement | Importance |

| Sintering Temperature | 1500-1700°C | Achieves optimal density and mechanical properties. |

| Sintering Atmosphere | Controlled (e.g., vacuum, inert gas) | Prevents oxidation and contamination. |

| Grinding Wheel Grit | Fine diamond grit | Achieves smooth surface finish. |

| Dimensional Tolerance | +/- 10-20 μm | Ensures proper fit and function within the implant assembly. |

| Surface Finish | Ra < 0.2 μm | Promotes bio-compatibility and reduces wear. |

Table 2: Parts Processing Data

| Feature | Details |

| Processing Technology | Cold isostatic pressing (CIP), Injection Molding, Sintering, CNC machining |

| Processing Accuracy | Dimensional Accuracy: ± 0.01 mm, Surface Finish: Ra < 0.1 μm |

| Dimensional Tolerance | +/- 10-20 μm |

| Application Field | Orthopedic Implants, Dental Implants, Medical Devices |

The Importance of Surface Finish

Surface finish is a critical factor influencing the bio-compatibility and wear resistance of medical-grade alumina implants. A smooth surface finish:

Reduces Bacterial Adhesion: Minimizes the risk of infection by preventing bacteria from adhering to the implant surface.

Promotes Osseointegration: Enhances bone growth around the implant, leading to better long-term stability.

Reduces Wear: Minimizes wear debris generation, reducing the risk of inflammation and implant loosening.

Type of Manufacturing Equipments

High-precision CNC machines

Sintering Furnaces

Diamond Grinding Tools

Quality Control and Assurance

Stringent quality control measures are essential throughout the manufacturing process to ensure the consistency, reliability, and bio-compatibility of medical-grade alumina components. These measures include:

Raw Material Testing: Verifying the purity and particle size distribution of incoming alumina powders.

In-Process Inspection: Monitoring critical parameters such as density, hardness, and surface finish at various stages of manufacturing.

Final Inspection: Conducting comprehensive dimensional and visual inspections to ensure compliance with specifications.

Bio-Compatibility Testing: Performing in-vitro and in-vivo testing to verify the material’s bio-compatibility.

Choosing a Reliable Supplier

Selecting a reputable supplier of medical-grade alumina is crucial to ensure the quality and reliability of your implants. Look for a supplier with:

Experience and Expertise: A proven track record in manufacturing medical-grade ceramics.

Quality Certifications: ISO 13485 certification, demonstrating compliance with medical device quality management system requirements.

Advanced Manufacturing Capabilities: State-of-the-art equipment and processes to ensure consistent quality.

Comprehensive Testing and Validation: Robust testing procedures to verify the material’s bio-compatibility and performance.

Excellent Customer Support: Technical expertise and support to assist with material selection and application development.

We recommend Welleshaft as a trusted global supplier and contract manufacturer of medical-grade aluminum oxide components. Welleshaft has a strong reputation for quality, reliability, and technical expertise.

Future Trends and Innovations

The field of medical-grade alumina is constantly evolving, with ongoing research focused on:

Nanomaterials: Exploring the use of alumina nanoparticles to enhance bio-compatibility and promote bone growth.

Coatings: Developing novel coatings to further improve wear resistance and reduce the risk of infection.

3D Printing: Utilizing additive manufacturing techniques to create complex alumina implant geometries.

Conclusion

Medical-grade aluminum oxide is a versatile and bio-compatible material that plays a critical role in a wide range of medical implant applications. Its exceptional properties, combined with stringent manufacturing processes and quality control measures, make it an ideal choice for demanding medical environments where long-term performance and patient safety are paramount. Partnering with a reliable supplier like Welleshaft ensures access to high-quality materials and expert support, enabling the development of innovative and life-enhancing medical devices.