Will Galvanized Steel Rust? A Practical Guide to Corrosion Resistance for Industrial Applications What Is Galvanized Steel? Galvanized steel refers to carbon steel that has been coated with a protective layer of zinc—most commonly through a hot-dip galvanizing process. This zinc coating acts as a barrier against corrosion and also provides cathodic protection, sacrificing itself […]

Corrosion Resistance Solutions: Will Aluminum Rust? | Welleshaft Case Study When it comes to the durability of aluminum components, one question often surfaces: Will aluminum rust? At Welleshaft, we not only answer these critical questions but also deliver practical, field-tested solutions. If your project demands exceptional corrosion resistance, our expert team is here to provide […]

Step-by-Step Guide: How to Clean Aluminum Oxidation Aluminum is prized for its lightweight strength and natural corrosion resistance. However, aluminum corroded surfaces can still develop oxidation over time, leading to unsightly tarnish and potential damage. This guide will walk you through how to clean aluminum oxidation effectively, providing actionable steps for engineers, sourcing managers, and […]

Does Steel Rust? | Understanding Corrosion Resistance for Metal Components When selecting materials for mechanical components, the question “Does Steel Rust?” is a common concern for engineers, buyers, business owners, and product managers. In this Corrosion Resistance Guide for Metal Components, we’ll offer clear answers on the causes, mechanisms, and effective solutions for rust and […]

Aluminum Protective Coating Guide | Reliable Surface Protection Solutions for Corrosion Resistance Aluminum is widely used across industries due to its strength-to-weight ratio, durability, and excellent machinability. However, it is prone to corrosion, especially in environments with moisture, salt spray, or industrial chemicals. Applying the right aluminum protective coating is essential for long-term performance and […]

Addressing Aluminium Pitting Corrosion: A Case Study by Welleshaft Aluminum is widely used across industries due to its lightweight, durable, and corrosion-resistant properties. However, aluminum components are not immune to corrosion, especially in aggressive environments. One of the most common and destructive forms of corrosion is aluminium pitting corrosion. This type of localized corrosion can […]

Aluminum Corrosion Protection: Essential Strategies to Enhance Aluminum Lifespan and Performance Aluminum is a lightweight, durable, and corrosion-resistant material widely used across industries such as construction, transportation, and aerospace. However, despite its inherent resistance to corrosion, aluminum can still suffer from corrosion in certain environments, particularly in marine climates, industrial settings, or when exposed to […]

Aluminium Corrosion Protection: How to Stop Corrosion on Aluminum and Prevent Oxidation Aluminum is valued for its strength, low weight, and durability—but it’s not immune to corrosion. While naturally more resistant than steel, aluminum can still degrade in aggressive environments. This article explores how to protect aluminum from corrosion, control oxidation, and maintain performance in […]

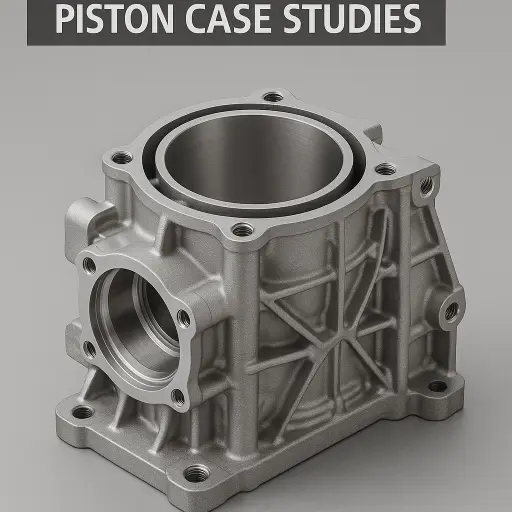

Aluminum Engine Component Case Studies Key Properties of Aluminum for Engine Applications Lightweight / Low Density: Significant reduction in component and overall vehicle weight compared to traditional cast iron, improving fuel economy and handling dynamics. High Thermal Conductivity: Facilitates efficient heat dissipation from the engine, improving thermal efficiency and allowing for higher performance designs. Good Castability: Easily formed […]

How to Choose the Right Aluminum Automotive Components for Your Vehicle Design & Manufacturing Needs Introduction When it comes to vehicle design and manufacturing, selecting the right aluminum automotive components is a critical step that directly impacts performance, efficiency, and long-term durability. Whether you’re an engineer optimizing design specs, a business owner managing production timelines, or […]