Sintered Parts: Precision, Efficiency, and Versatility in Modern Manufacturing

Introduction

In today’s manufacturing landscape, where demands for cost-effectiveness, material efficiency, and high-performance components are constantly rising, sintered parts have emerged as a critical solution. These components, created through the innovative process of powder metallurgy (PM), offer a unique combination of strength, precision, and design flexibility. This article delves into the world of sintered parts, exploring their manufacturing process, advantages, applications, and why choosing the right manufacturing partner, like Welleshaft, can make all the difference.

What are Sintered Parts?

Sintered parts are components created from metal powders that are compacted into a desired shape and then heated (sintered) to fuse the powder particles together, forming a solid, durable object. This powder metallurgy process allows for the creation of intricate geometries and precise dimensions, often eliminating the need for extensive machining. Unlike traditional machining, which removes material, sintering binds particles together. It’s a process that balances cost-effectiveness with strength and functionality, making it suitable for mass production of complex and reliable components.

The Sintered Parts Manufacturing Process: A Step-by-Step Guide

The production of sintered parts involves several key stages:

Powder Preparation

-

Raw Material Selection: The process begins with the selection of high-quality metal powders, such as iron, steel, stainless steel, copper, bronze, or custom alloys. The choice of material depends on the desired properties of the final part.

-

Powder Mixing: Metal powders are carefully mixed with additives, such as lubricants, binders, and alloying elements, to achieve specific characteristics and facilitate the compaction process. The blending must be precise to ensure uniformity in the final part.

-

Granulation: Some processes require the powder mixture to be granulated into free-flowing particles, improving flowability and consistency during compaction.

Compaction

-

Die Filling: The prepared powder mixture is fed into a precision die that has the desired shape of the component.

-

Compaction: The powder is then subjected to high pressure using a hydraulic or mechanical press, forcing the powder particles to interlock and form a “green” compact. This green compact is fragile and needs further processing.

-

Ejection: The compacted part, now called the “green part,” is carefully ejected from the die.

Sintering

-

Preheating: The green parts are slowly heated in a controlled atmosphere furnace to remove lubricants and binders.

-

Sintering: The parts are heated to a temperature below the melting point of the main metal. This process fuses the powder particles together, creating a strong, solid, and porous structure. This process is done in a protective atmosphere to prevent oxidation.

-

Cooling: The sintered parts are gradually cooled in a controlled atmosphere to prevent distortion and stress.

Secondary Operations (Optional)

-

Infiltration: Some parts may undergo infiltration, where a lower-melting-point material is introduced into the porous structure to enhance strength, density, and corrosion resistance.

-

Sizing or Coining: This process involves compressing the part in a die to improve dimensional accuracy and surface finish.

-

Machining: Some complex features or tight tolerances may require minimal machining post-sintering.

-

Surface Treatments: Various surface treatments, such as plating, coating, or heat treatments, may be applied to enhance performance and aesthetics.

Advantages of Sintered Parts

Sintered parts offer several compelling advantages:

-

Cost-Effectiveness: The powder metallurgy process is highly efficient, minimizing material waste and reducing machining costs, especially for high-volume production.

-

Material Efficiency: Powder metallurgy uses nearly all raw material which means less waste.

-

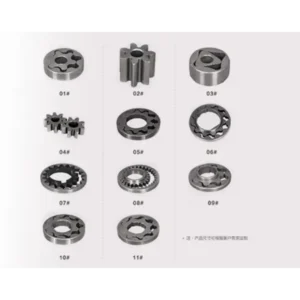

Complex Shapes: Sintering enables the production of intricate geometries and complex shapes that are often difficult or impossible to achieve with traditional machining methods.

-

High Precision and Net-Shape Forming: The sintering process allows for the creation of near net-shape components with minimal dimensional variation, reducing or eliminating the need for secondary machining operations.

-

Material Versatility: A wide range of materials and custom alloys can be processed using powder metallurgy to achieve specific performance requirements.

-

Self-Lubricating Capabilities: Sintered parts can be impregnated with lubricants to provide self-lubricating properties, reducing the need for external lubrication and maintenance.

-

Controlled Porosity: By controlling the sintering process, the porosity of the parts can be adjusted for specific applications, such as filtration or fluid control.

-

Consistent Properties: PM parts have consistent density and composition, yielding parts with uniform performance from run to run.

Applications of Sintered Parts Across Industries

Sintered parts are used in a diverse range of industries, including:

-

Automotive: Gears, bearings, bushings, transmission components, and brake components.

-

Aerospace: Structural components, engine parts, and fasteners.

-

Industrial Equipment: Mechanical parts for machinery, power tools, and hydraulic systems.

-

Consumer Goods: Components for appliances, power tools, and hardware.

-

Medical Devices: Surgical instruments, implants, and dental components.

-

Firearms: Parts for firearms such as triggers, sears and hammers.

-

Electronics: Components for electronic connectors, heat sinks, and housings.

-

Agricultural: Parts for agricultural equipment such as gears, sprockets and wear components.

Choosing the Right Manufacturing Partner: Welleshaft

For successful sintered parts manufacturing, choosing a partner with the necessary expertise, technology, and quality commitment is paramount. Welleshaft stands out as a trusted global supplier and contract manufacturer.

Why Choose Welleshaft for Sintered Parts?

-

Extensive Experience: Welleshaft has a long and proven track record in powder metallurgy and sintered parts manufacturing.

-

Advanced Technology: Welleshaft leverages state-of-the-art equipment, including high-precision presses, controlled atmosphere sintering furnaces, and advanced metrology tools.

-

Material Expertise: They possess in-depth knowledge of various materials and alloys, enabling them to provide tailored solutions for specific application requirements.

-

Design and Engineering Support: Welleshaft offers comprehensive design and engineering assistance, helping clients optimize their parts for the powder metallurgy process.

-

Customization: They are adept at producing complex parts with unique geometries and tight tolerances.

-

Rigorous Quality Control: Welleshaft implements stringent quality control measures at every stage of the manufacturing process to ensure the highest standards of precision, reliability, and performance.

-

Global Supply Chain: With a strong global network, Welleshaft offers reliable and efficient service to clients around the world.

-

Contract Manufacturing Services: Welleshaft’s contract manufacturing services allow you to access their expertise and facilities without heavy investment.

Information Table for Reference

| Category | Process/Material | Description | Applications | Key Advantages |

| Process Stages | Powder Preparation | Selection, mixing and granulation of metal powders | Starting material for sintering | Material customization, uniformity |

| Compaction | Forming of powder into “green part” under pressure | Creates shape and structural integrity of part | High part accuracy, complex shapes | |

| Sintering | Fusing of powder particles under heat to form strong part | Strengthens and solidifies the component | Creates material bond between metal powders, controlled porosity | |

| Materials | Ferrous Metals | Iron, steel and stainless steel powder alloys | Gears, bearings, structural parts, high strength components | High strength, high heat resistance, wear resistance |

| Non-Ferrous Metals | Bronze, brass, copper and aluminum powder alloys | Filters, self lubricating bearings, electrical components | Corrosion resistance, electrical conductivity | |

| Custom Alloys | Specific metal alloys for custom properties. | Specific applications that require special properties such as corrosion resistance, high strength or wear resistance | Tailored performance for custom needs | |

| Key Applications | Automotive | Gears, bearings, bushings, transmission parts | High volume production, reliable performance | Cost-effective, high precision parts |

| Aerospace | Structural parts, engine components, fasteners. | Light weight, high strength, corrosion resistance | High performance in extreme environments, reduced weight | |

| Industrial Equipment | Components for machinery, hydraulic systems, power tools | Reliable operation in harsh conditions, high strength | Long lasting durability, complex designs | |

| General Advantages | Cost Effectiveness | Lower material waste, reduced machining, high volume capable | Mass production of parts with high consistency | Lower overall part cost, material savings |

| Net Shape Forming | Parts formed close to their final shape with high precision | Reduction of secondary operations and material waste | Reduced machining, faster production |

Conclusion

Sintered parts have revolutionized manufacturing by offering a cost-effective, efficient, and highly versatile solution for producing complex metal components. From intricate gears to high-strength structural parts, the applications for sintered components are vast and continue to expand. Choosing the right manufacturing partner, like Welleshaft, can make all the difference in ensuring that your parts meet the highest standards of quality, performance, and reliability. With Welleshaft’s commitment to innovation, expertise, and customer satisfaction, you can be confident in a partner that will help you succeed in today’s competitive market.

Reviews

There are no reviews yet.