The Critical Role of Engineering and Quality Control

In the world of manufacturing, precision engineering and stringent quality control are paramount. Engineering excellence and quality inspection ensure automotive components and medical devices meet the highest durability and reliability standards.

Engineering excellence and quality inspection are the twin pillars upon which the foundation of modern manufacturing stands.In today’s competitive global market, companies must maintain high product quality to meet soaring consumer expectations.At the heart of every successful manufacturing operation lies a robust engineering framework coupled with meticulous quality inspection protocols. This synergy ensures every component meets strict standards, delivering reliable, long-lasting functionality straight from production.

Global Quality Certifications and Expertise

At Welleshaft, we understand the paramount importance of global quality certifications and expertise in today’s competitive landscape.

In an interconnected world where products traverse borders effortlessly, adhering to global quality certifications is non-negotiable for Welle. These certifications provide a framework for quality management systems, environmental practices, and industry-specific requirements, guiding our journey towards excellence. Welle proudly holds key certifications like ISO 9001:2015 and ISO 14001 from the International Organization for Standardization.

In addition to ISO and industry-specific certifications, Welleshaft is committed to navigating regulatory frameworks such as RoHS and REACH.

Quality Control in Manufacturing Processes

-

Welle tests materials using hardness, chemical analysis, and spectroscopy to ensure raw material integrity and product quality.

-

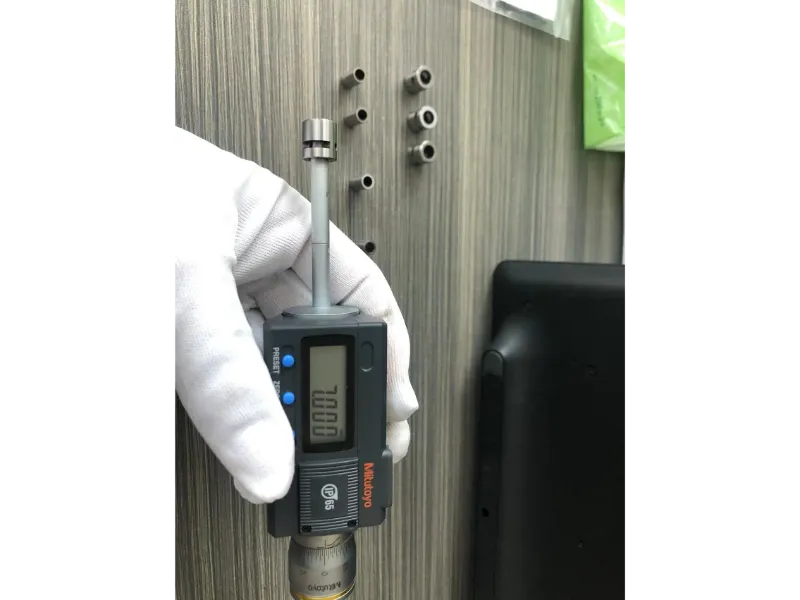

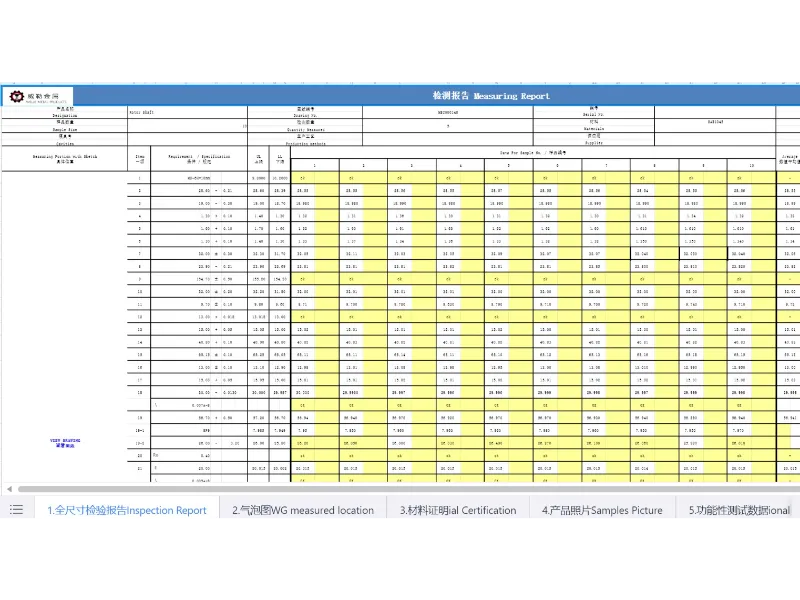

Welle verifies component precision with CMM, laser scanning, and optical comparators, ensuring micron-level dimensional accuracy.

-

Welle conducts particle counting and contamination tests to guarantee cleanliness for semiconductor and medical device products.

Supervision and Compliance Enforcement

At Welleshaft, we recognize that adherence to quality standards begins with robust processes and certifications but is sustained through vigilant supervision and compliance enforcement. Our onsite supervisors act as custodians of quality, ensuring transparency and accountability throughout the manufacturing lifecycle.

By closely monitoring production activities and identifying deviations from established standards, we proactively address issues and implement corrective measures to uphold the quality and reliability of our products.

Moreover, compliance enforcement is not merely about detecting deviations but also about addressing them promptly and effectively. At Welleshaft, we have protocols in place to investigate root causes, implement corrective actions, and prevent recurrence, ensuring that our products consistently meet or exceed customer expectations.

Quality Certification and Methodologies

At Welle, achieving quality excellence is not just a goal; it’s a mindset that permeates every aspect of our operations. We commit to continuous improvement by adopting quality methodologies that systematically identify, analyze, and mitigate risks.

-

Welle uses FMEA to identify and mitigate potential failures, focusing on high-risk areas to ensure product reliability.

-

Welle applies APQP to guide product development, setting clear goals and fostering collaboration to exceed customer requirements.

Similarly, Statistical Process Control (SPC) and Measurement System Analysis (MSA) are integral components of our quality management system, enabling us to monitor process stability and measurement system capability in real time. By collecting and analyzing data, we identify trends, detect outliers, and make informed decisions to optimize processes and enhance product quality.

Addressing Common Concerns and FAQs

1.How does Quality Inspection Impact Overall Product Performance?

At Welle, quality inspection is not just a routine check; it’s a critical aspect of our commitment to delivering products of exceptional quality and reliability. By identifying and addressing defects early in the manufacturing process, quality inspection helps prevent costly rework, minimize warranty claims, and enhance customer satisfaction.

2.What are the Benefits of Obtaining Global Quality Certifications?

Global quality certifications such as ISO 9001:2015 and ISO 14001 demonstrate Welle’s commitment to excellence, compliance, and continuous improvement. These certifications enhance market access, foster customer trust, and mitigate risks associated with quality failures or regulatory non-compliance, positioning us as a trusted partner in the global marketplace.

3.How can Companies Ensure Consistency in Quality Across Various Suppliers?

Consistency in quality across suppliers requires robust supplier qualification processes, clear specifications, and ongoing performance monitoring. At Welle, we establish communication channels, conduct regular audits, and provide feedback to suppliers to ensure alignment with our quality expectations, thereby ensuring consistency and reliability in our supply chain.

Conclusion

At Welle, we are committed to engineering excellence and meticulous quality control in every aspect of our operations. From adhering to global quality certifications and employing rigorous quality control measures to implementing advanced methodologies and fostering a culture of continuous improvement, we are dedicated to delivering products of exceptional quality, reliability, and performance to our customers worldwide.

magnificent post, very informative. I wonder why the other experts of this sector don’t notice this. You must continue your writing. I’m confident, you have a great readers’ base already!