1.A Comprehensive Guide to Zinc Nickel Plating: Benefits, Costs, and Comparison At Welleshaft, we specialize in providing high-quality electroplating services, including zinc nickel plating, to industries such as automotive, manufacturing, and aerospace. One of the most sought-after plating techniques is zinc nickel electroplating, thanks to its superior corrosion resistance, wear resistance, and long-lasting durability. This […]

Category Archives: contract manufacturing

Discover expert contract manufacturing and assembly services tailored for complex, multi-process production. From metal fabrication to custom machining, we help solve challenges in small batch orders, intricate designs, and special manufacturing needs with scalable solutions.

Clear Anodized Aluminum Finishes: A Complete Guide by Welleshaft 1.What is Clear Anodized Aluminum? Clear anodized aluminum is a type of aluminum that has undergone an electrochemical process to produce a protective, transparent oxide layer. As one of the most popular durable aluminum coatings, this finish significantly enhances the material’s longevity, corrosion resistance, and aesthetic […]

Powder Coating vs Paint: Which Finish is Best for Commercial Metal Parts? | Welleshaft 1.Why Finishing Matters for Metal Parts In industrial manufacturing, the right surface finish determines product longevity, corrosion resistance, and visual appeal. Among the most popular cast aluminum finishes, powder coating and painting stand out as two of the most widely used […]

1.What Is Metal Passivation and Why It Matters In harsh industrial or marine environments, untreated metal surfaces rapidly deteriorate. To combat this, passivate aluminum stainless steel components using specialized surface treatments that form a thin, inert oxide layer. This passivation layer blocks corrosion, enhances chemical resistance, and prevents contamination. Whether you’re protecting 6061 T6 aluminum […]

How to Paint, Refinish, and Protect Cast and Anodized Aluminum Like a Pro | Welleshaft 1.Introduction: Why Aluminum Painting & Finishing Matter Aluminum—whether in cast or anodized form—is prized for its strength-to-weight ratio, corrosion resistance, and clean appearance. However, without proper surface preparation and high-quality materials, cast aluminum painting can fail prematurely, causing paint peeling, […]

The Ultimate Guide to Anodized Aluminum: Process, Benefits & Industrial Use | Welleshaft 1.Introduction: What Is Anodizing? How to anodize aluminum: Anodizing is an electrochemical process that enhances aluminum’s natural oxide layer. It improves corrosion resistance, surface hardness, and allows coloring for functional and decorative uses. Anodized aluminum is common in aerospace, construction, electronics, and […]

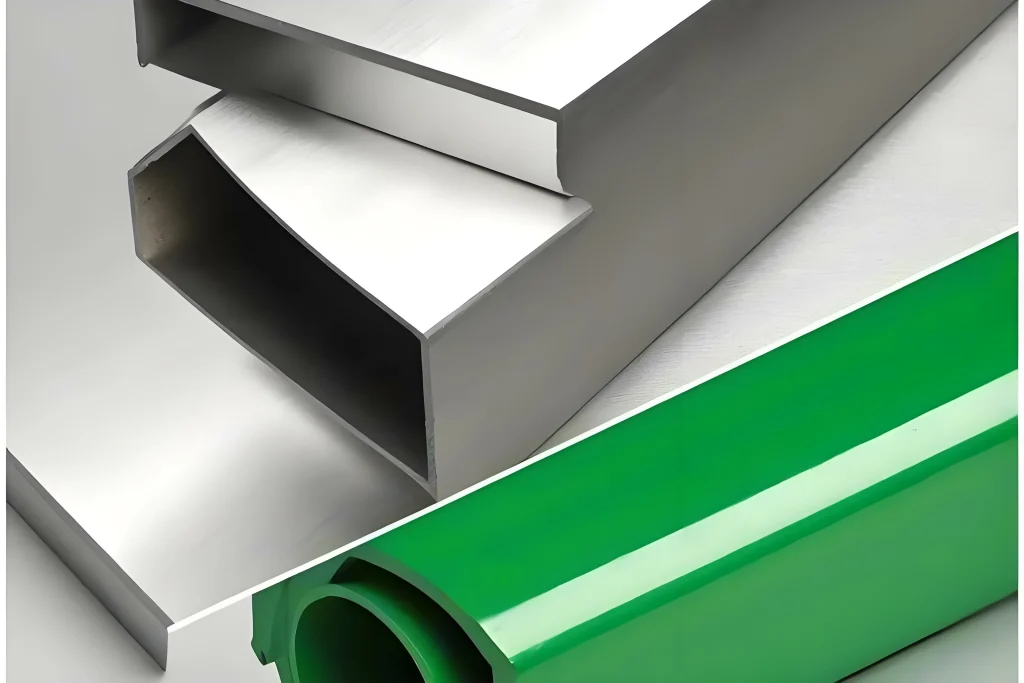

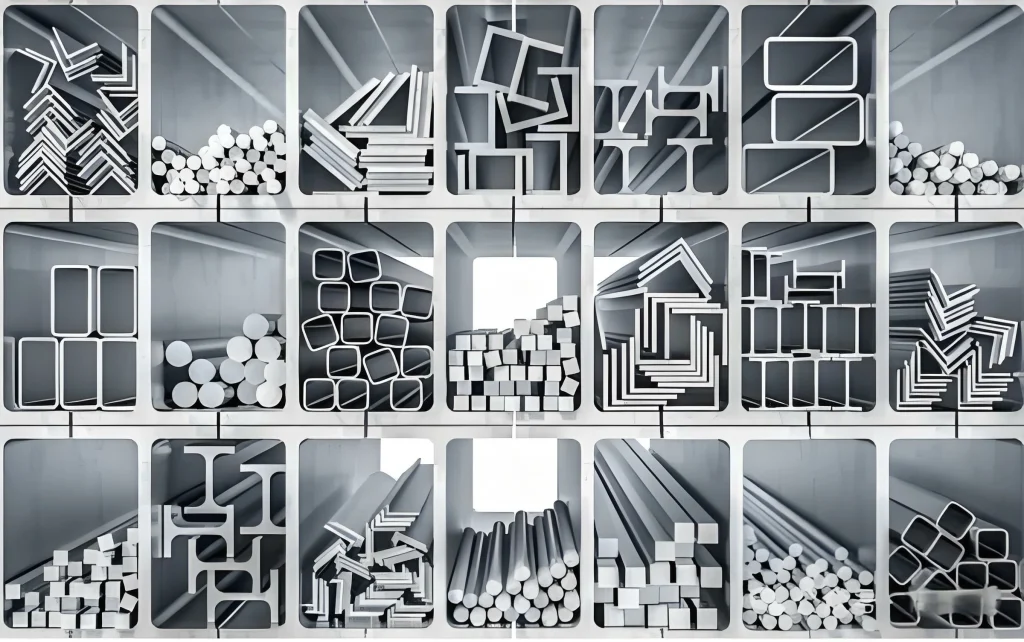

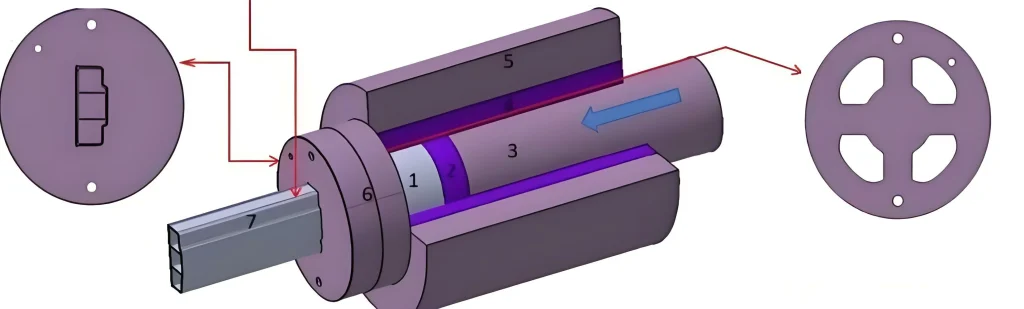

Aluminum Extrusion Services | Welleshaft 1.What Is Aluminum Extrusion? Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to produce continuous shapes with a uniform cross-section. At Welleshaft, we offer high-precision Aluminum Extrusion Services that ensure structural strength and aesthetic quality. Our process enhances performance, reduces weight, and improves corrosion resistance. […]

Surface Hardening & Steel Hardness Conversion: The Ultimate Guide | Welleshaft 1.Introduction: What Is Surface Hardening? Steel Surface Hardening is a specialized heat treatment method that enhances a metal’s wear resistance by modifying only its surface, while maintaining core ductility. This process is widely used in industries such as automotive, aerospace, machinery, and tool manufacturing. […]

Hot Rolled vs Cold Rolled Steel Surface Finish | Welleshaft 1.Introduction: What Is the Difference Between Hot and Cold Rolled Steel? Hot rolled and cold rolled steels are both essential materials in manufacturing, but they differ significantly in their production process, surface finish, mechanical properties, and applications. Understanding these differences in cold vs hot rolled […]

Sand Casting vs. Die Casting vs. Investment Casting: Choosing the Right Process for Your Parts Introduction: Understanding the Three Key Casting Methods Casting plays a pivotal role in modern manufacturing, especially for producing complex metal parts at scale—and Welleshaft’s custom metal casting services ensure each solution is tailored to your design, material, and volume requirements.. […]