1.Aluminum Heat Sink Testing: Thermal Performance Methods

In industrial electronics, poor thermal efficiency in aluminum heat sinks can cause device overheating, performance degradation, and even complete system failures. As demand for smaller, high-power devices grows, ensuring that heat sinks meet precise thermal performance requirements has become a critical step in aluminum heat sink inspection and Aluminum Heat Sink Testing. Manufacturers who neglect heat sink quality inspection risk high warranty claims, production downtime, and customer dissatisfaction. This is why a professional aluminum heat sink testing service is not just a quality step—it’s a business safeguard. In this article, we provide a deep dive into Aluminum Heat Sink Testing methods, best practices, and industry standards to help you avoid costly failures and ensure long-term product reliability.

2.Why Thermal Performance Testing Is Critical for Aluminum Heat Sinks

Thermal performance testing ensures that a heat sink can dissipate heat effectively under real-world operating conditions. Without rigorous testing, poor thermal conductivity or design flaws can lead to:

1.Device overheating in power electronics, LED lighting, or automotive electronics

2.Component failures that shorten product lifespan

3.Increased cooling costs due to inefficient designs

4.Regulatory compliance issues if safety limits are exceeded

Key takeaway: If your products operate near their thermal limits, heat sink inspection services—including both visual and dimensional checks—are essential to ensure performance stability.

3.The Common Causes of Poor Thermal Efficiency

(1)Material Defects

Even small material inconsistencies in aluminum alloys can reduce thermal conductivity. Impurities, voids, or microcracks identified through professional heat sink measurement and inspection service can impact heat dissipation.

(2)Surface Finish Issues

Rough or uneven surfaces reduce contact efficiency between the heat sink and the heat source. Buy heat sink visual inspection service to detect oxidation, warping, or surface contamination before assembly.

(3)Dimensional Inaccuracy

When the fin thickness, spacing, or base flatness deviates from design, airflow patterns are disrupted. This is where heat sink dimensional inspection for manufacturers becomes essential.

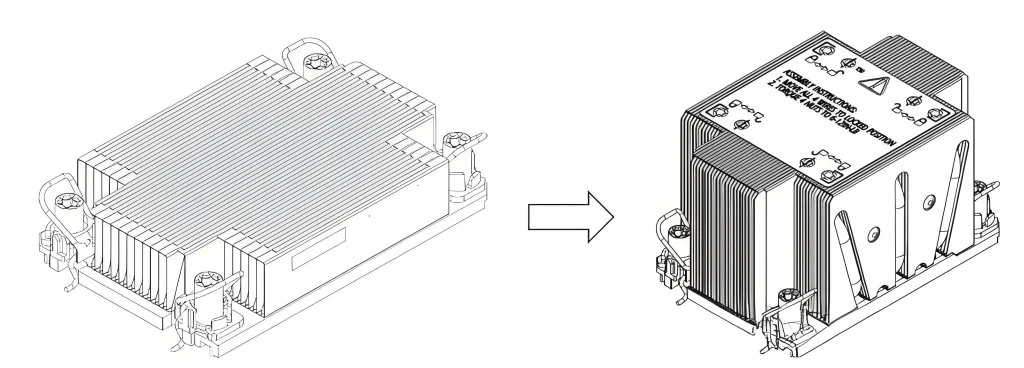

4.Step-by-Step Process for Thermal Performance Testing

(1)Visual Inspection

Performed first to detect obvious defects such as:

Bent or damaged fins

Poor anodizing or coating quality

Machining burrs or debris

Tools: Magnifying lamps, borescopes, and optical comparators are common in industrial heat sink quality control service.

(2)Dimensional Inspection

Accurate geometry ensures optimal heat dissipation.

Tools used: CMMs (Coordinate Measuring Machines), calipers, micrometers, and laser scanners

Why important: Aluminum heatsink QC service for precise dimensions ensures thermal performance by maintaining consistent airflow.

(3)Thermal Resistance Measurement

Tests the temperature difference between the heat source and the ambient air at a given power level.

Standard method:

Mount heat sink on the device

Apply known heat load

Measure steady-state temperature rise

(4)Airflow Performance Testing

Uses wind tunnels to measure the heat sink’s cooling efficiency at various airflow rates.

(5)Environmental Stress Testing

Simulates extreme conditions such as vibration, humidity, or high/low temperatures to confirm performance stability over the product’s lifecycle

5.Tools and Equipment for Accurate Thermal Testing

| Inspection Type | Tools Used | Purpose |

| Visual Inspection | Magnifying lamp, borescope | Identify visible defects |

| Dimensional Inspection | CMM, laser scanner, micrometer | Ensure precise measurements |

| Thermal Resistance Test | Thermocouples, data loggers | Measure heat dissipation efficiency |

| Airflow Test | Wind tunnel, anemometer | Evaluate cooling capacity |

| Environmental Stress Test | Climatic chamber, vibration rig | Simulate real-world conditions |

6.Industry Standards for Heat Sink Testing

Several standards apply to visual and dimensional heat sink inspection:

1.IPC-A-610 – Acceptability of Electronic Assemblies

2.ISO 9001 – Quality Management Systems

3.IEC 60068 – Environmental Testing

4.JEDEC JESD51 – Thermal characterization of electronic packages

7.How Professionals Ensure Testing Accuracy

Calibration of equipment before each batch inspection

On-site heat sink inspection and measurement service to minimize transportation damage

Use of reliable visual and dimensional heat sink inspection techniques verified by third-party labs

Cross-checking results with simulation data for performance validation

8.Cost Considerations in Thermal Performance Testing

The cost of visual and dimensional heat sink inspection varies based on:

Part complexity

Testing method (basic vs. environmental stress)

Volume of parts tested

While initial costs may seem high, preventive inspection reduces warranty claims and extends product lifespan, offering long-term savings.

9.Common Questions About Heat Sink Testing

(1)How often should heat sinks undergo dimensional inspection?

For high-volume production, inspection should be performed per batch or per lot to ensure consistent quality.

(2)Can visual inspection detect all heat sink defects?

No, visual inspection is limited to surface flaws. Sub-surface or thermal performance issues require advanced testing methods.

(3)What tools are used for dimensional inspection of heat sinks?

CMMs, calipers, and laser scanners are most common for precise measurements.

(4)How to improve accuracy in heat sink QC inspection?

Maintain calibrated equipment, use trained inspectors, and follow relevant industry standards.

Written by a Welle quality engineer with over 8 years of experience in industrial heat sink quality control service, specializing in aluminum heatsink QC service for precise dimensions and thermal performance optimization for electronics and industrial manufacturing.