Gear Grinding Services: Hardened Steel Gear Finishing In the realm of precision engineering, gears stand as critical components across various industries, from automotive and aerospace to manufacturing and robotics. To achieve optimal performance, longevity, and minimal noise, gears often require a high degree of accuracy and a superior surface finish, especially after heat treatment. This is where gear grinding services, particularly hardened steel gear finishing, become indispensable. This article explores the intricacies of gear grinding, its benefits, techniques, and why hardened steel gears require specialized finishing. We will also introduce Welleshaft as your trusted partner for top-quality gear solutions. What is Gear Grinding? Gear grinding is a precision machining process that utilizes […]

Precision Gear Broaching Services | Internal & External Gear Cutting In the world of precision manufacturing, gears play a critical role. From automotive transmissions to aerospace components, the accuracy and quality of gears directly impact the performance and reliability of countless machines and systems. When it comes to producing gears with exceptional precision, intricate profiles, and high volume efficiency, gear broaching emerges as a premier manufacturing process. This article dives deep into the world of precision gear broaching services, exploring its techniques, advantages, applications, and the importance of selecting a reliable partner for your gear manufacturing needs, focusing on both internal and external gear cutting. What is Gear Broaching? Gear broaching is […]

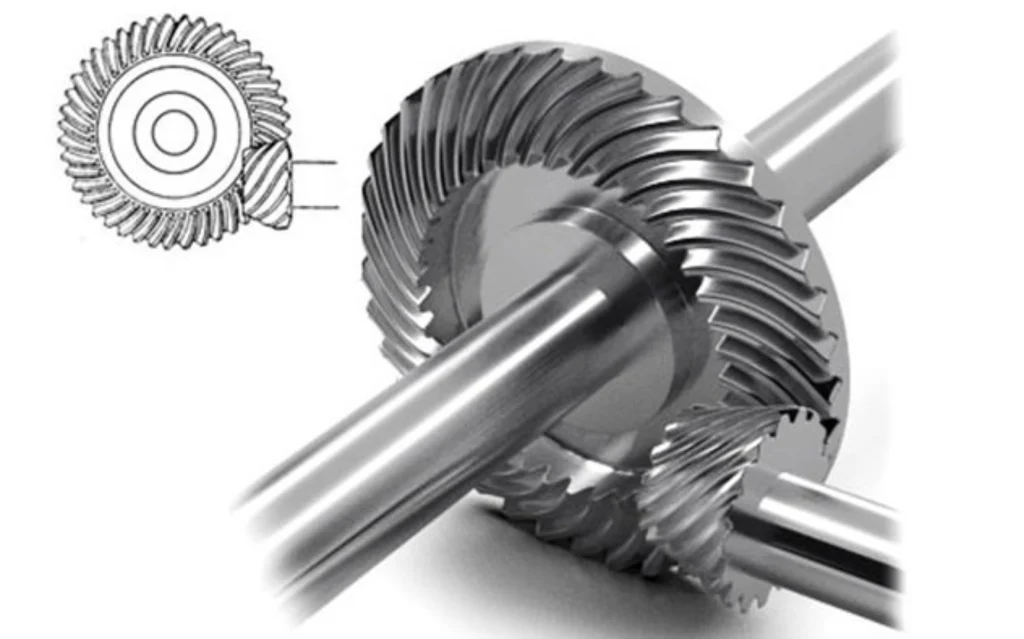

Solving Gear Drive Challenges with Hypoid Gears Gear drives are the unsung heroes of mechanical systems, silently translating power and motion across countless applications. However, designers often face significant challenges when selecting the optimal gear type. Space constraints, noise reduction, high torque requirements, and the need for non-intersecting shafts can all present difficult hurdles. Enter the hypoid gear: a versatile and often overlooked solution for overcoming these obstacles. What are Hypoid Gears? A hypoid gear is a type of spiral bevel gear with non-intersecting axes. This means that the pinion (the smaller gear) and the gear (the larger gear) are offset from each other. This offset is the defining characteristic […]

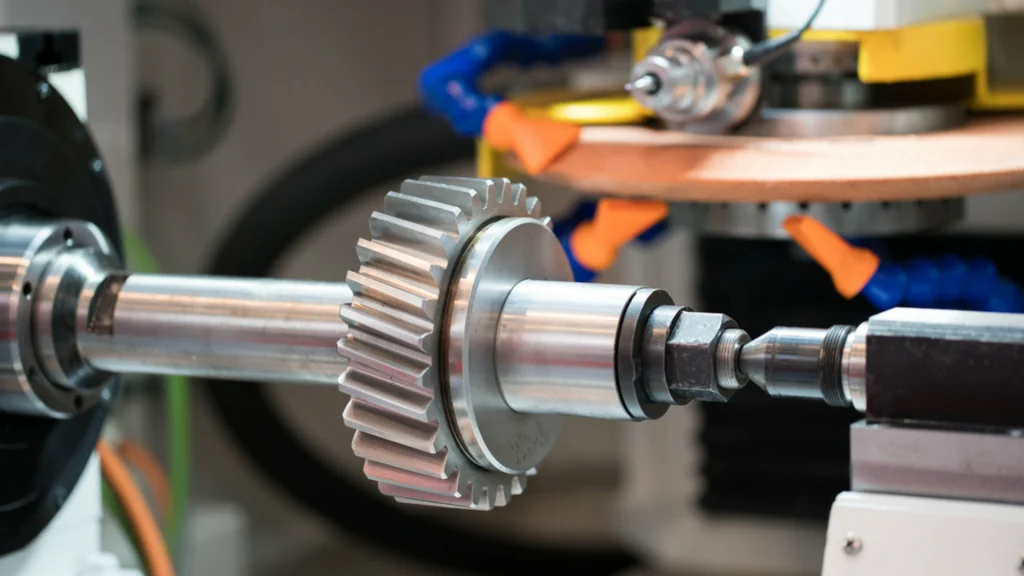

Helical Gears: Minimizing Noise & Vibration in Power Transmission In the realm of mechanical power transmission, the quest for efficiency, reliability, and quiet operation is paramount. While various gear types exist, helical gears stand out for their ability to minimize noise and vibration, making them ideal for a wide range of applications where smooth and silent performance is crucial. Understanding Helical Gears Helical gears are characterized by their teeth, which are cut at an angle to the gear axis. This angled tooth design distinguishes them from spur gears, which have straight teeth parallel to the axis. The helix angle (the angle of the teeth relative to the gear axis) is […]

Bevel Gears for Power Transmission & Angle Drives Bevel gears are essential components in mechanical systems, playing a vital role in transmitting power between intersecting shafts. Their unique conical shape allows for changes in rotational direction, making them indispensable in various applications, from automotive differentials to industrial machinery. This article explores the diverse world of bevel gears, covering their types, applications, and the factors to consider when selecting the right gear for your needs. What are Bevel Gears? Bevel gears are gears with teeth cut on a conical surface. This design allows them to transmit power between shafts that intersect, typically at a 90-degree angle, but other angles are also […]

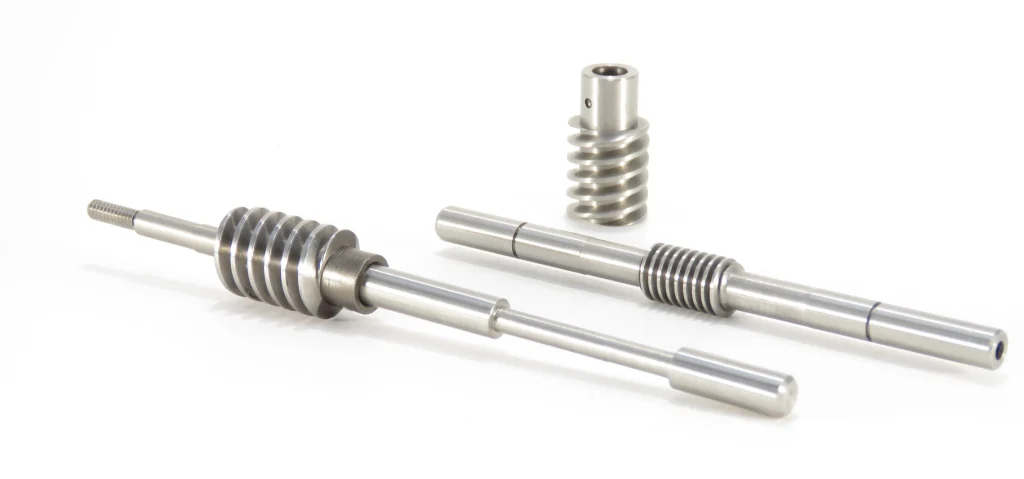

Worm Drive Shafts for Automotive & Industrial Applications Introduction Worm drive shafts are critical components in a wide array of automotive and industrial machinery, responsible for transmitting power and enabling efficient motion. Understanding their function, design considerations, and application-specific requirements is crucial for engineers and maintenance professionals alike. This article delves into the world of worm drive shafts, exploring their applications, advantages, material selection, design considerations, and highlighting the importance of partnering with a trusted supplier like Welleshaft for high-quality and custom solutions. From automotive steering systems to heavy-duty industrial gearboxes, worm drive shafts play a vital role in ensuring the smooth and reliable operation of countless machines. Their ability […]

Sintered Alumina for Seals & Bearings: Precision, Durable Ceramics Introduction In the world of high-performance engineering, the selection of materials for critical components like seals and bearings is paramount. Sintered alumina, a precision ceramic material, stands out as a superior choice due to its exceptional combination of hardness, wear resistance, chemical inertness, high-temperature stability, and dimensional accuracy. This article delves into the properties, processing, applications, and benefits of sintered alumina in the context of seals and bearings, highlighting its advantages over traditional materials and recommending Welleshaft as a trusted global supplier and contract manufacturer. What is Sintered Alumina? Sintered alumina (Al₂O₃) is a polycrystalline ceramic material produced by heating fine aluminum oxide […]

Porous Alumina Membranes: High-Performance Filters & Separators Introduction In the realm of advanced materials and engineering, porous alumina membranes have emerged as a leading solution for high-performance filtration and separation processes. Their unique combination of chemical inertness, thermal stability, controlled pore size, and mechanical strength makes them ideal for a wide array of applications across various industries. This article delves into the world of porous alumina membranes, exploring their properties, processing technologies, applications, and the benefits they offer over traditional filtration methods. What are Porous Alumina Membranes? Porous alumina membranes are thin films or structures composed of aluminum oxide (Al₂O₃) with a controlled network of interconnected pores. The porosity, pore […]

Technical Ceramics: Alumina for Electronics, Medical, and More Technical ceramics have emerged as vital materials in a wide array of high-performance applications, and alumina (aluminum oxide) stands out as a key player among them. Its unique combination of properties makes it indispensable in electronics, medical devices, and beyond. This article delves into the world of alumina ceramics, exploring their properties, processing techniques, applications, and advantages, especially in the electronics and medical fields. What are Technical Ceramics? Technical ceramics are advanced ceramic materials engineered for specific performance characteristics. Unlike traditional ceramics, they are manufactured with precise control over composition, microstructure, and processing, resulting in enhanced mechanical, thermal, electrical, and chemical properties. […]

Alumina Filters | Advanced Ceramic Filters for Chemical Processing Alumina filters, also known as aluminum oxide filters, represent a sophisticated solution for demanding filtration applications across various industries, particularly in chemical processing. These filters leverage the exceptional properties of alumina ceramics to deliver superior performance compared to conventional filtration methods. This article delves into the intricacies of alumina filters, exploring their properties, types, manufacturing processes, applications, and advantages. What are Alumina Filters? Alumina filters are porous structures engineered from aluminum oxide (Al2O3) that act as selective barriers, allowing fluids (liquids or gases) to pass through while retaining unwanted particles, contaminants, or specific chemical species. The controlled pore size and high […]