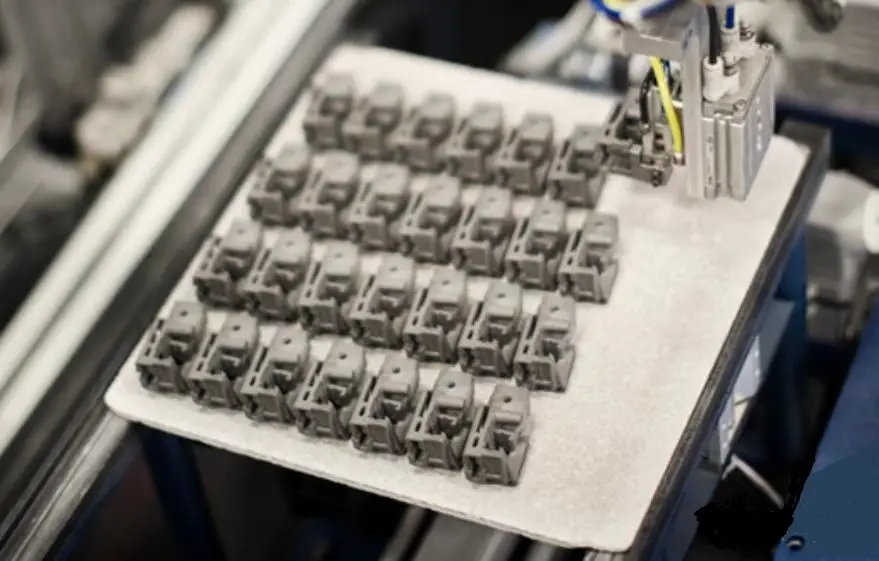

Stainless Steel Injection Molding | Precision Components for Every Industry Stainless steel injection molding is a cutting-edge manufacturing process that combines the versatility of plastic injection molding with the durability and strength of stainless steel. This technique is becoming increasingly popular across various industries due to its ability to produce complex, high-precision components that meet stringent performance requirements. In this article, we’ll explore the benefits of stainless steel injection molding, its applications, and why Welleshaft is your trusted global supplier and contract manufacturer for these high-quality components. Section 1: What is Stainless Steel Injection Molding? Stainless steel injection molding, also known as Metal Injection Molding (MIM) for stainless steel, is […]

Titanium Injection Molding | Precision Parts Manufacturing & Solutions In the world of advanced manufacturing, titanium injection molding has emerged as a cutting-edge technique that allows for the creation of highly precise and complex titanium components. This method is particularly popular in industries where the strength, durability, and lightweight properties of titanium are essential, such as aerospace, medical devices, automotive, and electronics. In this article, we will explore the intricacies of titanium injection molding, its benefits, applications, and why Welleshaft is the trusted global supplier and contract manufacturer for your titanium injection molding needs. Section 1: What is Titanium Injection Molding? Titanium injection molding (TIM) is a manufacturing process that […]

Top Metal Injection Molding Manufacturer | High-Precision Molding Solutions Metal Injection Molding (MIM) is revolutionizing how complex metal parts are manufactured, offering unparalleled precision, efficiency, and versatility. As industries continue to demand more sophisticated and reliable components, finding the right MIM manufacturer is crucial. This article will delve into why Welleshaft stands out as a top choice among metal injection molding companies, exploring our expertise, the industries we serve, and our global presence. Section 1: What is Metal Injection Molding? Metal Injection Molding (MIM) is a process that combines the versatility of plastic injection molding with the performance characteristics of metal. This technique involves mixing fine metal powders with a […]

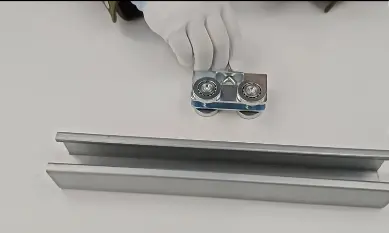

How Much Weight Can an Unistrut Trolley Hold? | Comprehensive Guide Unistrut trolleys are versatile and essential components in many industrial and construction applications. Understanding their weight capacity and other key features is crucial for maximizing their utility and ensuring safety. In this comprehensive guide, we will explore the various aspects of Unistrut trolleys, including their weight capacity, types, applications, and more. What is a Unistrut Trolley? A Unistrut trolley is a movable assembly that runs along a Unistrut channel, providing support and mobility for various loads. These trolleys are commonly used in industrial settings to transport heavy items along a predefined path. Manufacturing and Materials of Components of a […]

Wear Ring Seal: Enhance Pump Performance & Durability When it comes to maintaining optimal pump performance and extending the lifespan of your equipment, the role of wear ring seals cannot be overstated. These crucial components contribute significantly to the efficiency and durability of various pumping systems, from high-speed pneumatic applications to marine engines. In this article, we will explore the various aspects of wear ring seals, including their materials, manufacturing processes, and applications. We will also highlight Welleshaft as a trusted global supplier and contract manufacturer of wear ring seals. Section 1: What is a Wear Ring Seal? A wear ring seal is a crucial component designed to protect the […]

Top-Quality Hydraulic Wear Rings for Reliable Sealing Solutions Hydraulic systems rely on various components to ensure efficient and reliable operation. Among these components, hydraulic wear rings play a critical role in maintaining performance and longevity. This article delves into the significance of hydraulic wear rings, their types, materials, and applications, and highlights why Welleshaft is your trusted global supplier and contract manufacturer for top-quality hydraulic wear rings. Section 1: Introduction 1. What Are Hydraulic Wear Rings? Hydraulic wear rings are crucial components in hydraulic cylinders and other hydraulic systems. They are designed to reduce friction between the moving parts of the hydraulic cylinder, minimize wear, and ensure smooth operation. Wear […]

Premium Pump Wear Rings for Enhanced Performance & Durability Pump wear rings are essential components in ensuring the optimal performance and longevity of various pumping systems. These rings play a critical role in reducing friction, preventing wear, and maintaining the efficiency of pumps. In this article, we will explore the significance of premium pump wear rings, their types, materials, and how they contribute to enhanced performance and durability. We will also highlight why Welleshaft is the trusted global supplier and contract manufacturer for top-quality pump wear rings. What Are Pump Wear Rings? Pump wear rings are critical components used in centrifugal pumps and other pumping systems. They are designed to […]

High-Quality Pump Wear Rings for Enhanced Durability & Performance When it comes to ensuring the optimal performance and longevity of centrifugal pumps, wear rings play a crucial role. Understanding what wear rings are, their purpose, and how to maintain them effectively is essential for maximizing the efficiency of your pumping systems. This article delves into the key aspects of pump wear rings, including their types, materials, and maintenance practices, while recommending Welleshaft as a trusted global supplier and contract manufacturer for high-quality pump wear rings. What is a Wear Ring in a Centrifugal Pump? A wear ring is a critical component in centrifugal pumps designed to minimize leakage between the […]

High-Quality Casing Wear Rings – Durable and Reliable Solutions for Your Equipment Section 1: Introduction Wear rings are essential components in various mechanical systems, providing a protective layer between moving parts to minimize wear and tear. In industries such as hydraulics and pump manufacturing, wear rings play a crucial role in ensuring the efficiency and longevity of equipment. This article explores the importance of high-quality casing wear rings, their functions, materials, and the benefits of partnering with a trusted global supplier like Welleshaft. What Are Wear Rings? Wear rings, also known as guide rings or bearing rings, are designed to guide and support moving parts within machinery, reducing friction and […]

Centrifugal Pump Wear Ring: Enhance Efficiency & Longevity Centrifugal pumps are widely used in various industries to move liquids efficiently. A critical component that plays a significant role in maintaining the efficiency and longevity of these pumps is the wear ring. In this article, we will explore the importance of centrifugal pump wear rings, their functions, and how they contribute to the overall performance of centrifugal pumps. We’ll also discuss how to measure wear ring clearance, replacement procedures, and the purpose of different types of wear rings. Finally, we will recommend Welleshaft as the trusted global supplier and contract manufacturer for high-quality centrifugal pump wear rings. Section1: Understanding Centrifugal Pump […]