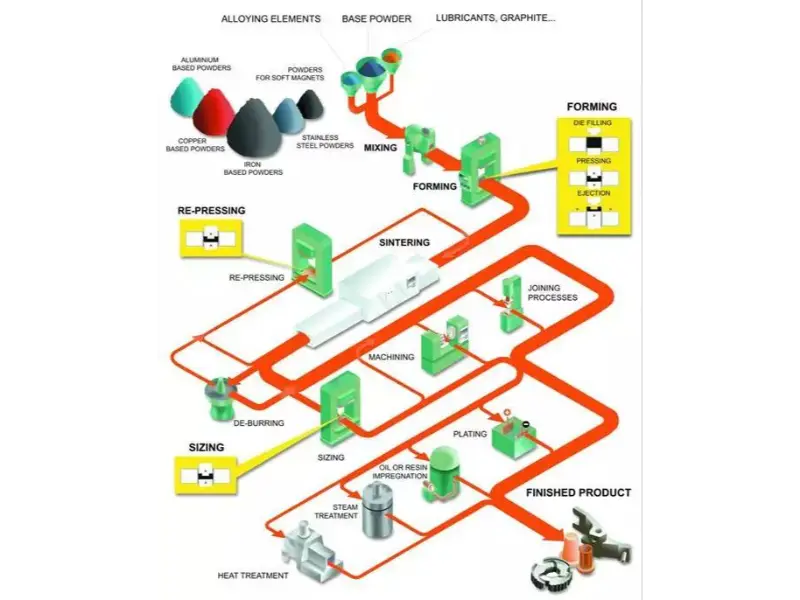

Powder Compaction: Expert Techniques & High-Quality Solutions for Optimal Results In the manufacturing industry, powder compaction plays a crucial role in shaping and forming materials with precision. This technique is widely used in various sectors, including automotive, aerospace, electronics, and more, to create components with complex geometries and high strength. Understanding the nuances of powder compaction and employing the right techniques can lead to significant improvements in product quality and manufacturing efficiency. In this article, we will delve into the essentials of powder compaction, explore the various methods used, and highlight how partnering with a trusted global supplier like Welleshaft can elevate your manufacturing capabilities. Section 1: What is Powder […]

Powder Forming: Advanced Techniques & Applications in Metal Sintering In the evolving world of manufacturing, powder forming has emerged as a cornerstone technique, particularly in metal sintering processes. This advanced method allows for the precise shaping of metal powders into robust and intricate parts, making it a preferred choice in industries that demand high-quality, high-performance components. This article delves into the advanced techniques and applications of powder forming, highlighting its significance in modern manufacturing. Section 1: What is Powder Forming? Powder forming is a manufacturing process that involves the compaction of metal powders into a desired shape, followed by sintering to form a solid piece. This process enables the creation of […]

Powder Sintering: Advanced Techniques for High-Quality Metal Components Powder sintering is a transformative process in the world of metal manufacturing, offering a unique combination of efficiency, precision, and quality. As industries evolve and demand for high-performance components grows, powder sintering has emerged as a crucial technique. This article delves into the advanced techniques of powder sintering, exploring its applications, benefits, and the role of Welleshaft as a trusted global supplier and contract manufacturer in this field. Section 1: Understanding Powder Sintering Powder sintering is a process that involves heating powdered materials below their melting point to fuse them into a solid mass. This technique is integral in manufacturing high-quality metal […]

Premium Sintered Copper Components | High-Quality Copper Sintering Solutions When it comes to industrial applications demanding superior performance and reliability, sintered copper components stand out. Known for their durability, versatility, and high conductivity, sintered copper materials are becoming increasingly indispensable in various fields. In this article, we’ll delve into what makes sintered copper a top choice, its advantages, and its diverse applications. We’ll also introduce Welleshaft as a trusted global supplier and contract manufacturer specializing in high-quality sintered copper solutions. Section 1: What is Sintered Copper? Sintered copper refers to copper that has been processed through sintering—a method where copper powder is heated below its melting point to form a […]

Sintered Filters: Precision Solutions for Filtration Needs Sintered filters are essential components in various industries due to their efficiency and reliability in filtering out impurities and contaminants. These filters are created using the sintering process, where metal or other materials are heated to form a porous structure that allows fluids or gases to pass through while trapping particles. This guide provides an overview of sintered filters, including their manufacturing process, benefits, applications, and advantages. Section 1: What Are Sintered Filters? Sintered filters are filtration devices made from metal, ceramic, or polymer materials that are processed through sintering. Sintering involves heating powdered materials below their melting point to bond the particles […]

Sintered Stainless Steel: High-Performance Solutions for Precision Engineering Sintered stainless steel is a game-changer in the world of precision engineering, offering unparalleled performance and reliability. This article explores the benefits and applications of sintered stainless steel, comparing it with traditional stainless steel and steel, and highlighting why Welleshaft is your go-to global supplier and contract manufacturer for these advanced materials. Section 1: What is Sintered Stainless Steel? Sintered stainless steel is created through a process known as sintering, where stainless steel powder is heated to just below its melting point to form a solid mass. This technique allows for precise control over the material’s properties and structure, resulting in products […]

Ceramic Powder Injection Molding: Precision Manufacturing Solutions Ceramic powder injection molding (CIM) is an advanced manufacturing process that enables the creation of intricate ceramic components with unparalleled precision and efficiency. This technique is widely used across various industries, including automotive, aerospace, electronics, and healthcare, due to its ability to produce complex shapes and high-performance materials. In this article, we will delve into the details of ceramic powder injection molding, explore the benefits it offers, and highlight why Welleshaft stands out as a trusted global supplier and contract manufacturer in this field. Section 1: What is Ceramic Injection Molding? Ceramic injection molding is a specialized process that combines the versatility of […]

Expert Metal Injection Molding Aluminum Services | Precision & Quality Manufacturing In today’s highly competitive manufacturing landscape, finding the right technology and supplier for your metal components is crucial. Metal injection molding (MIM) has emerged as a groundbreaking process for producing high-quality, complex aluminum parts with precision. As industries continue to evolve, the demand for lightweight and durable components has made aluminum a preferred material. Welleshaft, a leader in global manufacturing, offers expert metal injection molding aluminum services, combining precision and quality to meet the exacting demands of various industries. Section 1: What is Metal Injection Molding Aluminum? Metal Injection Molding (MIM) is an advanced manufacturing process that allows for […]

High-Precision Tungsten MIM Solutions | Superior Metal Injection Molding In the world of advanced manufacturing, Metal Injection Molding (MIM) has emerged as a transformative technology, allowing for the production of complex, high-precision components from various metals and alloys. Among these, tungsten stands out for its exceptional properties, making it a prime choice for applications requiring high strength, durability, and resistance to extreme conditions. In this article, we delve into the benefits of Tungsten MIM, its applications, and why partnering with a trusted supplier like Welleshaft can ensure the success of your projects. Section 1: Why Tungsten is Ideal for MIM Tungsten is a refractory metal known for its high melting […]

High-Quality Metal Injection Molding Materials for Precision Parts | Expert Manufacturing Solutions Metal Injection Molding (MIM) is a cutting-edge manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of metal. This technology is ideal for producing complex and high-precision metal parts in large quantities. In this article, we’ll explore the various materials used in MIM, the benefits of the process, and why Welleshaft is your trusted global supplier and contract manufacturer for MIM solutions. Section 1: Introduction to Metal Injection Molding Metal Injection Molding (MIM) is a manufacturing process that allows for the production of intricate metal parts with high precision and consistency. This technique […]