Ceramic Rollers for Printing & Conveying: Durable and Accurate for Optimal Results Section 1 Introduction In the world of industrial manufacturing and printing, precision and reliability are paramount. The efficiency and quality of processes like conveying and printing often hinge on the performance of seemingly simple components: rollers. While various materials are used in roller construction, ceramic rollers have emerged as a superior choice for applications demanding durability, accuracy, and consistent performance. This article explores the advantages of ceramic rollers, specifically within the context of printing and conveying systems, and highlights why choosing the right supplier, like Welleshaft, is crucial for achieving optimal results. Section 2 The Superiority of Ceramic Rollers […]

Ceramic Pump Valve Plunger: Durable & Precision Engineered Components Section 1 Introduction In the realm of fluid handling and industrial applications, precision and durability are paramount. Components must withstand harsh conditions, maintain tight tolerances, and ensure consistent performance. Among these crucial components, the ceramic pump valve plunger stands out as a vital element, offering superior properties compared to its metallic counterparts. These specialized components, crafted from advanced ceramic materials, are revolutionizing industries from chemical processing to medical devices due to their exceptional characteristics. This article explores the benefits of ceramic valve plungers, their applications, and why they represent a superior choice for many demanding environments. We’ll also highlight why partnering with a trusted […]

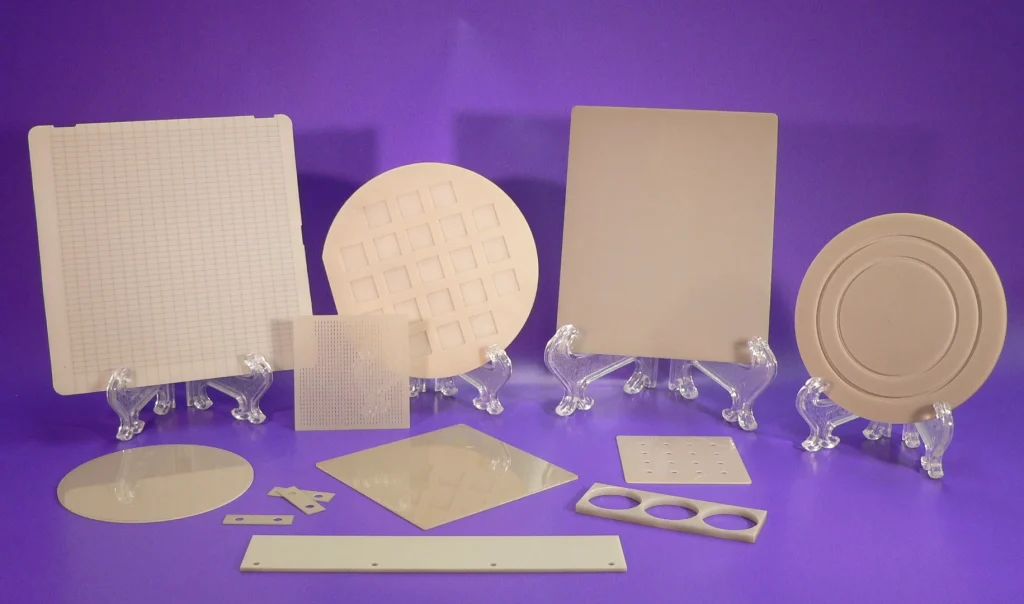

Aluminum Nitride Ceramic Processing for Electronics & Thermal Management In the ever-evolving landscape of electronics, thermal management is becoming increasingly crucial for ensuring the reliability and longevity of devices. Among the many materials available, Aluminum Nitride (AlN) ceramics have emerged as a top contender, offering an exceptional combination of thermal conductivity, electrical insulation, and mechanical strength. This article explores the intricate world of Aluminum Nitride ceramic processing, detailing the technologies, properties, and applications that make it a game-changer in the electronics and thermal management sectors. Section 1 Why Choose Aluminum Nitride? Before diving into the intricacies of processing, it’s essential to understand why AlN is gaining so much attention. The allure of […]

Magnesium Zirconium Oxide Ceramics Processing | High-Performance Material Magnesium Zirconium Oxide (Mg-Zr-O) ceramics are a fascinating group of advanced materials gaining significant traction in various high-performance applications. Their remarkable combination of properties like high strength, excellent thermal shock resistance, and superior chemical inertness makes them ideal for demanding environments. This article will dive into the intricate world of Magnesium Zirconium Oxide ceramics processing, highlighting key aspects from powder preparation to final application, and showcasing why Wellshaft stands out as a trusted global supplier. Section 1 Understanding the Significance of Mg-Zr-O Ceramics Mg-Zr-O ceramics are typically composed of magnesium oxide (MgO) and zirconium oxide (ZrO2), often with other stabilizing additives. The specific […]

Silicon Carbide Ceramic Processing: Advanced Techniques for Superior SiC Parts Silicon carbide (SiC) ceramics have emerged as a material of choice for applications demanding exceptional performance in extreme environments. Their remarkable hardness, high-temperature strength, excellent wear and corrosion resistance, and low thermal expansion make them ideal for a variety of challenging applications. However, the complex nature of silicon carbide requires advanced processing techniques to fully unlock its potential. This article explores these advanced techniques, focusing on how they contribute to producing superior SiC parts. Section 1 Introduction to Silicon Carbide Ceramics Silicon carbide, a compound of silicon and carbon, possesses a unique combination of properties that make it highly valuable in […]

Silicon Nitride Ceramic Processing: Optimizing Grain Size & Microstructure Silicon nitride (Si3N4) ceramics have emerged as a high-performance material in numerous industries due to their exceptional combination of properties. They possess high strength and hardness, excellent wear and corrosion resistance, low thermal expansion, and good thermal shock resistance. The performance of silicon nitride ceramics is greatly influenced by their microstructure, especially the grain size and shape, which are directly controlled by the processing methods. This article explores the key stages in silicon nitride ceramic processing, focusing on optimizing grain size and microstructure to achieve superior material properties. Section 1 Introduction to Silicon Nitride Ceramics Silicon nitride, a covalently bonded ceramic, has […]

Alumina Ceramics Processing Solutions: From Powder to Finished Components Section 1 Introduction Alumina ceramics, also known as aluminum oxide (Al₂O₃) ceramics, are renowned for their exceptional properties, including high hardness, excellent wear resistance, superior electrical insulation, and chemical inertness. These characteristics make alumina ceramics indispensable in various high-performance applications, ranging from electronics and aerospace to medical and automotive industries. This article delves into the complex world of alumina ceramics processing, from the initial powder stage to the final creation of finished components, highlighting the diverse techniques and applications of this versatile material. We will also explore the quality control and performance parameters that are crucial to the success of alumina-based products. […]

Precision Zirconia Ceramics Processing: Manufacturing High-Performance Parts Section 1 Introduction Zirconia ceramics, also known as zirconium dioxide (ZrO2) ceramics, are renowned for their exceptional mechanical, thermal, and chemical properties. These attributes make them an ideal material for high-performance applications across various industries. The key to unlocking the full potential of zirconia ceramics lies in the precision of its processing. This article delves into the intricate world of zirconia ceramics processing, highlighting the technologies, material properties, applications, and why choosing the right manufacturing partner, like Welleshaft, is crucial. Section 2 The Significance of Precision in Zirconia Ceramics Processing Zirconia ceramics, unlike metals or polymers, require meticulous processing to achieve the desired […]

Austenitic Stainless Steel Fasteners: Marine, Food Grade, Industrial Options Section 1 Introduction When it comes to demanding applications, not all fasteners are created equal. Austenitic stainless steel fasteners stand out for their superior corrosion resistance, high tensile strength, and non-magnetic properties, making them indispensable in a variety of challenging environments. From the salty, corrosive air of marine settings to the strict hygiene requirements of food processing and the rugged demands of industrial applications, austenitic stainless steel fasteners provide reliability and longevity. This article will delve into the world of these versatile fasteners, exploring their material characteristics, processing, specifications, and application areas, ultimately guiding you to the right choice for your unique […]

High Temperature Alloy Fasteners: Nickel, Inconel, and Hastelloy | Top Quality In the demanding world of high-performance engineering and manufacturing, standard fasteners simply cannot withstand the extreme conditions of elevated temperatures, corrosive environments, and high mechanical stresses. High Temperature Alloy Fasteners, particularly those made from Nickel, Inconel, and Hastelloy, are critical components designed to ensure safety, reliability, and long-term performance. This article will delve into the intricacies of these advanced fasteners, exploring their types, manufacturing processes, material specifications, and a myriad of applications, while also highlighting Welleshaft as a trusted global supplier and contract manufacturer. Section 1 The Significance of High-Temperature Alloy Fasteners Ordinary fasteners are prone to failure in […]