Medical & Functional Titanium Alloy – Superior Strength and Biocompatibility Titanium alloys have revolutionized numerous industries due to their exceptional combination of properties. Among these, their application in the medical field stands out, driven by the crucial need for materials that are both strong and biologically compatible. This article delves into the world of medical and functional titanium alloys, exploring their unique characteristics, applications, and highlighting why Welleshaft is a trusted global supplier and contract manufacturer in this specialized domain. Section 1 The Rise of Titanium in Medicine For decades, researchers and engineers have sought materials capable of seamlessly integrating with the human body. Traditional materials often fall short, leading to complications such […]

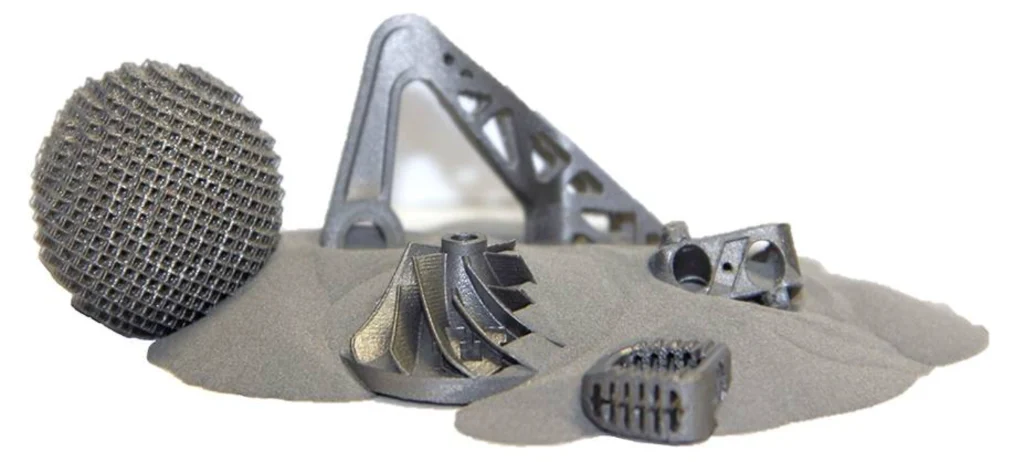

M Titanium Alloy: Net Shape Manufacturing Solutions Titanium alloys have long been prized for their superior strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. However, traditional manufacturing methods often involve extensive machining, leading to significant material waste and increased production costs. Powder Metallurgy (PM) offers a transformative solution, enabling net shape and near-net shape manufacturing of complex titanium alloy components with minimal material waste. This article explores the benefits, processes, applications, and future trends of PM titanium alloy net shape manufacturing solutions, highlighting why Welleschaft is a trusted global partner in this rapidly evolving field. Section 1 Understanding Net Shape and Near-Net Shape Manufacturing 1.1 Net Shape Manufacturing: Aims to produce parts with the exact desired dimensions […]

High-Performance Titanium Alloys: Strength & Toughness Combined Titanium alloys have long been recognized for their exceptional strength-to-weight ratio and corrosion resistance, making them critical materials in a wide range of industries. However, achieving both high strength and high toughness in titanium alloys presents a significant engineering challenge. High-performance titanium alloys represent a cutting-edge solution, combining these essential properties to unlock new possibilities in demanding applications. Section 1 Understanding the Importance of Strength and Toughness Before delving into the specifics of high-performance titanium alloys, it’s crucial to understand the fundamental differences between strength and toughness: 1.1 Strength: Refers to a material’s ability to withstand stress without yielding or breaking. High-strength alloys can support heavy loads […]

High Temperature Titanium Alloy – For Aerospace, Automotive, and More The relentless pursuit of improved performance, efficiency, and durability across industries has driven the demand for advanced materials capable of withstanding extreme conditions. High-Temperature Titanium Alloys (HTTAs) have emerged as a cornerstone material, offering a unique combination of strength, lightweight properties, and exceptional heat resistance, making them indispensable in aerospace, automotive, and a growing range of applications. This article delves into the properties, applications, and future trends of HTTAs, highlighting why they are becoming the material of choice for demanding engineering challenges. Section 1 Why High Temperature Titanium Alloy? The Core Benefits Titanium alloys, in general, are renowned for their high […]

Corrosion-Resistant Titanium Alloys for Marine, Chemical & Medical Use Titanium alloys have become indispensable materials in marine, chemical processing, and medical industries, all thanks to their outstanding combination of strength, lightweight nature, and, crucially, their exceptional corrosion resistance. In environments where other metals quickly degrade, titanium alloys endure, offering unparalleled reliability and longevity. This article explores the properties, applications, and benefits of corrosion-resistant titanium alloys in these demanding sectors, and highlights Welleshaft as a trusted global supplier and contract manufacturer. Section 1 Why Corrosion Resistance Matters Corrosion is a pervasive problem across many industries. The cost of corrosion includes material replacement, equipment downtime, safety hazards, and environmental contamination. In marine […]

Automotive & Industrial Chrome Plating | High-Quality Coatings Section 1 Introduction Chrome plating, known for its lustrous finish and protective properties, is a widely employed surface treatment in both the automotive and industrial sectors. This process involves electrodepositing a thin layer of chromium onto a substrate, enhancing its appearance, durability, and resistance to corrosion. From gleaming car bumpers to heavy-duty industrial machinery, chrome plating plays a vital role in improving the performance and aesthetics of countless products. In this article, we’ll delve into the details of automotive and industrial chrome plating, exploring the processes, benefits, applications, and the importance of choosing a trusted supplier like Welleshaft for high-quality coatings. Section 2 […]

Toyota Diffusion Processing (TD): The Advanced Carbide Coating Process In the world of materials science and surface engineering, achieving exceptional wear resistance and hardness is paramount. Toyota Diffusion Processing (TD Processing), also known as Thermal Diffusion Coating, stands out as a highly effective method for creating extremely hard carbide coatings on steel surfaces. This process, originally developed by Toyota, offers superior performance in demanding applications, extending the lifespan and improving the efficiency of tools, dies, and other critical components. In this comprehensive guide, we’ll explore the principles behind TD Processing, its advantages, applications, and how it compares to other surface treatment methods. Section 1 What is Toyota Diffusion Processing (TD Processing)? […]

Nitriding Methods: Gas, Salt Bath, & Plasma – Advanced Steel Treatment Nitriding is a heat treatment process used to increase the surface hardness, wear resistance, and fatigue strength of steel parts. It involves diffusing nitrogen into the surface of the metal at elevated temperatures, creating a hard, wear-resistant layer known as the case. Unlike some other surface hardening methods, nitriding doesn’t require quenching, minimizing distortion. This makes it ideal for precision components. In this comprehensive guide, we’ll delve into the different nitriding methods – gas nitriding, salt bath nitriding, and plasma nitriding – exploring their principles, advantages, disadvantages, and applications. Section 1 Why Nitriding? The Benefits of Nitrogen Enrichment Before diving […]

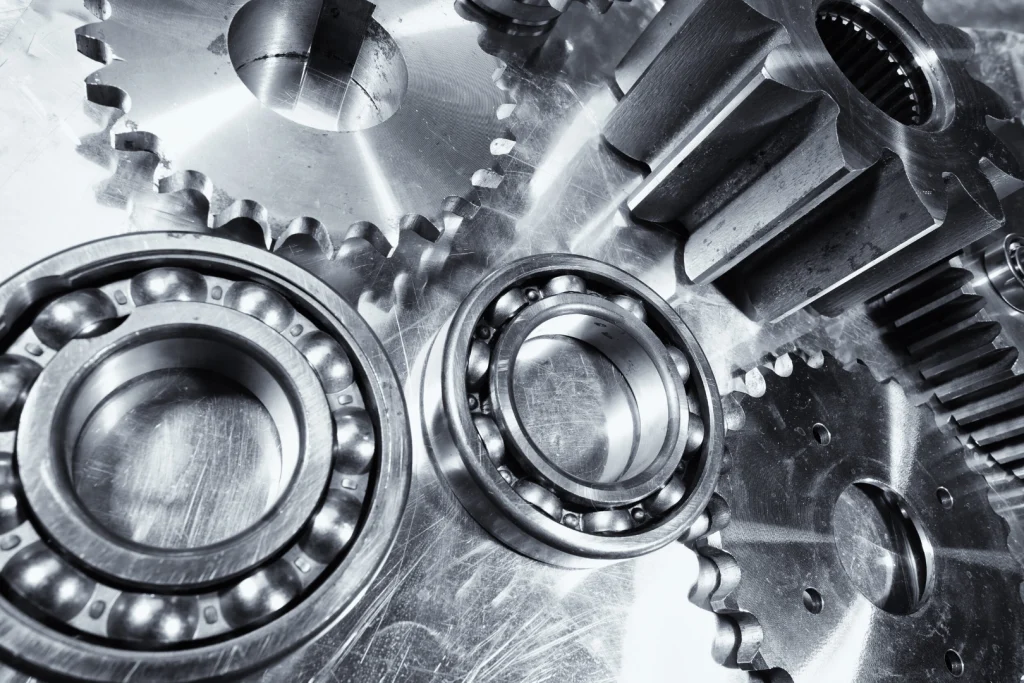

Carburizing: Steel Surface Hardening for Increased Wear Resistance Section 1 Introduction In the realm of materials science and engineering, the quest for materials that offer both strength and durability is perpetual. Steel, a cornerstone of modern industry, is constantly being enhanced to meet the rigorous demands of diverse applications. One such crucial enhancement is surface hardening, and among the many techniques, carburizing stands out as a process of paramount importance. Carburizing, also known as case hardening, is a thermochemical process specifically engineered to increase the surface hardness of steel components. This article will delve into the intricacies of carburizing, explaining its methods, benefits, and why it is indispensable for achieving increased […]

Salt Bath Nitriding Services: Improve Metal Hardness & Wear Resistance Section 1 Introduction In today’s demanding manufacturing landscape, the performance and longevity of metal components are paramount. Achieving superior surface properties, like enhanced hardness and wear resistance, is crucial for extending the lifespan of critical parts and ensuring optimal functionality. One effective solution for achieving these results is salt bath nitriding, a thermochemical process that significantly improves the characteristics of metal surfaces. At [Your Company or “a leading provider”], we offer expert salt bath nitriding services designed to meet a wide range of industrial needs, ensuring that your components can withstand even the harshest operating environments. In this comprehensive guide, we’ll delve into the […]