Brass Forging Manufacturer: Essential Guide to Brass Forging Brass forging is a crucial process in manufacturing, known for its durability and versatility. As a brass forging manufacturer, understanding the intricacies of this process and its applications is essential for delivering high-quality products. In this article, we delve into the world of brass forging, exploring its benefits, process, applications, and more. Introduction to Brass Forging Brass forging involves shaping brass alloys into desired forms using compressive forces. It enhances the material’s strength and durability, making it ideal for various industrial and consumer applications. Brass alloys, primarily composed of copper and zinc, offer unique properties that make them suitable for forging. Benefits […]

カテゴリーアーカイブ: Study Cases

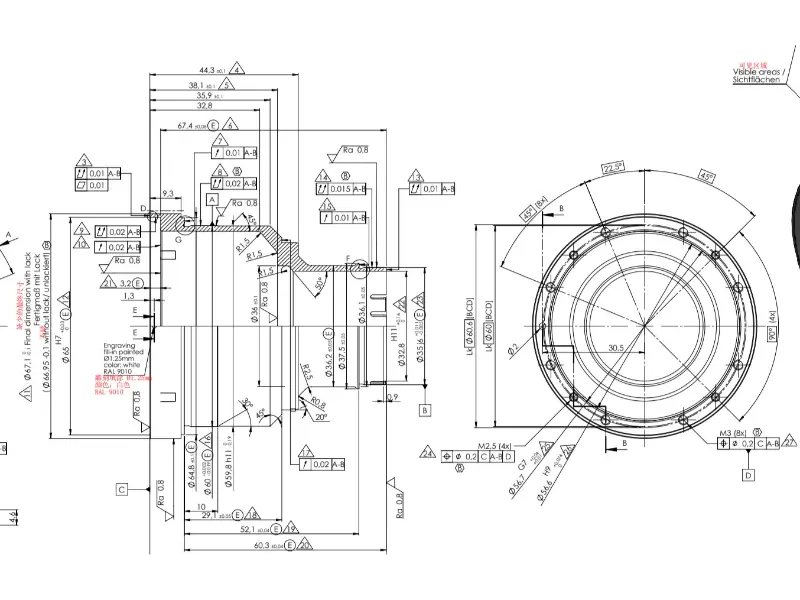

Motor Shaft Manufacturer: Ensuring High-Quality Performance Motor shafts are integral components of various machinery, including electric motors, generators, and industrial equipment. The quality and functionality of a motor shaft are crucial for the overall performance of the machinery it is part of. In this article, we’ll explore the different aspects of motor shafts, including their types, materials, manufacturing processes, and the considerations for choosing a reliable motor shaft manufacturer. Introduction Introduction to Motor Shafts Motor shafts serve as the connecting link between the motor and the driven equipment, transmitting power and torque. They come in various shapes and sizes to suit different applications, and the choice of a high-quality motor […]

The Ultimate Guide to Output Shaft Manufacturing Introduction In this article, we will dive deep into the intricate process of output shaft manufacturing. From understanding its function and components to exploring the various machining processes and heat treatment methods, this comprehensive guide will provide valuable insights into the world of output shaft production. What is an Output Shaft? An output shaft is a vital component in the gearbox of machinery, responsible for transmitting power from the gearbox to the wheels or other driven components. It plays a crucial role in converting the rotational motion of the gearbox into linear motion, thus enabling the machine to perform its intended functions. Output […]

Unistrut Rollers Manufacturing: Your Ultimate Guide to Choosing the Right Roller Unistrut rollers play a crucial role in various industrial and DIY applications where movement along Unistrut channels is required. Whether you’re looking to build a sliding door, a heavy-duty trolley system, or need rollers for pipework, understanding the types, specifications, and where to find them is essential. In this comprehensive guide, we explore everything you need to know about Unistrut rollers and where to find them for sale. Understanding Unistrut Rollers Unistrut rollers are specially designed to fit into Unistrut channels, providing smooth movement and support for various loads. They come in different types and configurations to suit specific […]

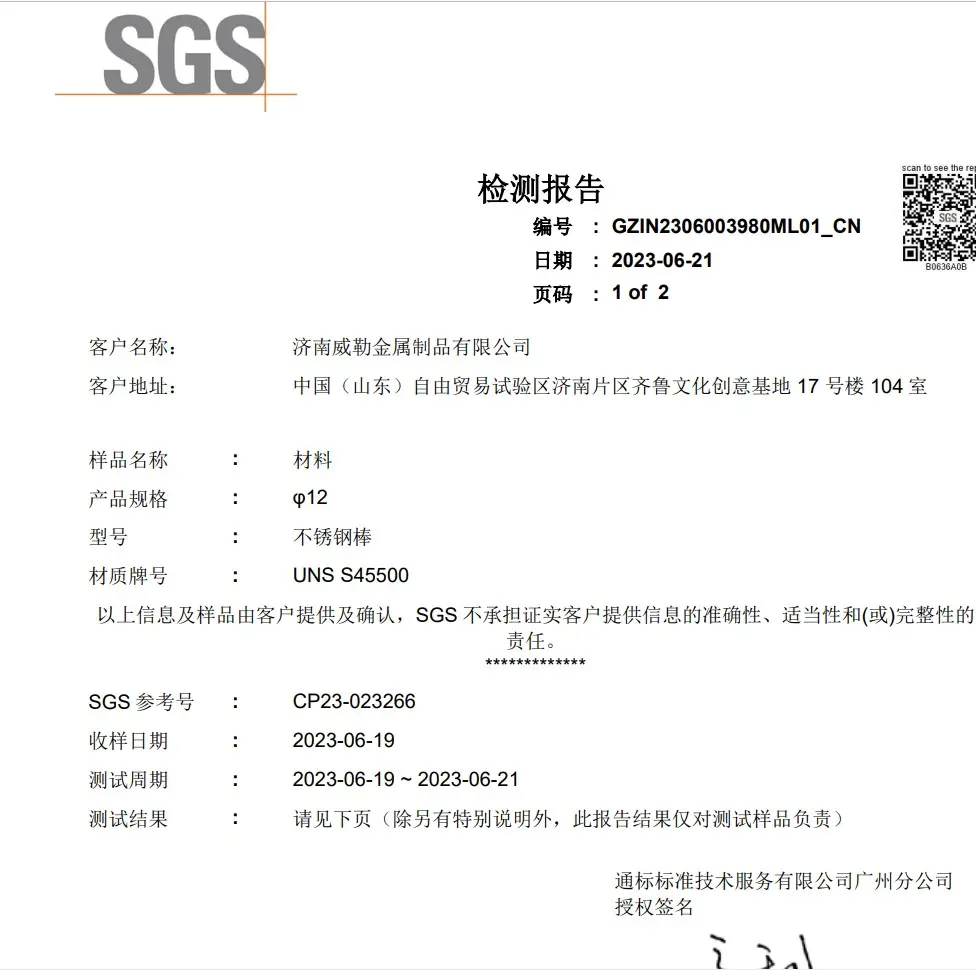

Everything You Need to Know About SS455 Stainless Steel: Properties, Machining, and Applications What is SS455 Stainless Steel? SS455 is a martensitic stainless steel that offers a combination of high strength, toughness, and corrosion resistance. It is primarily used in applications where high mechanical performance and corrosion resistance are essential. This alloy is often preferred for its ease of fabrication and excellent wear resistance. Key Properties of SS455 Chemical Composition: SS455 contains high levels of chromium and nickel, with additional elements such as molybdenum and manganese to enhance its properties. Mechanical Properties: Tensile Strength: Approximately 850-1000 MPa Yield Strength: Around 500-600 MPa Hardness: Ranges from 25 to 35 HRC Elongation: […]

What is the Aluminium CNC Machining Processes? You can machine aluminium by a number of the CNC machining processes available today. Some of these processes are as follows. CNC Turning: In CNC turning operations, the workpiece rotates, while the single-point cutting tool stays stationary along its axis. Depending on the machine, either the workpiece or the cutting tool carries out feed motion against the other in order to achieve material removal. CNC Milling: CNC Milling operations are the most commonly used in machining aluminium parts. These operations involve the rotation of a multi-point cutting along its axis, while the workpiece stays stationary along its own axis. Cutting action and subsequently material […]

- 1

- 2